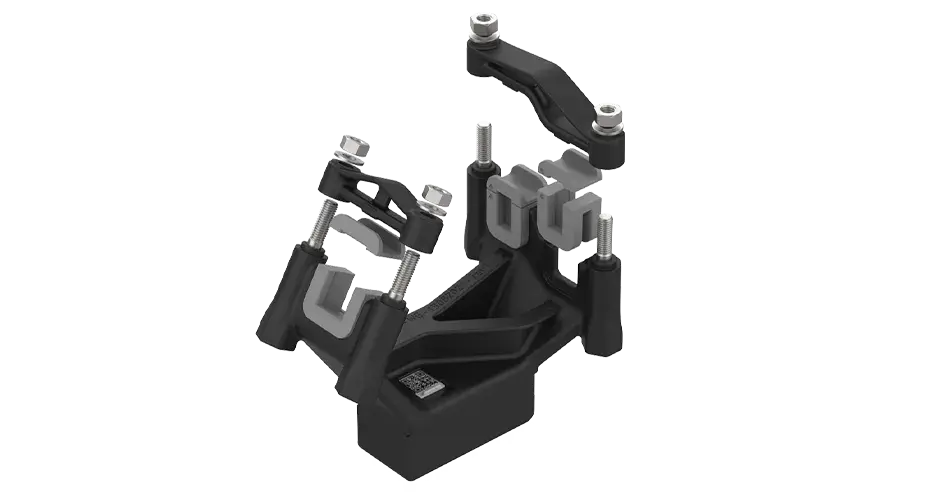

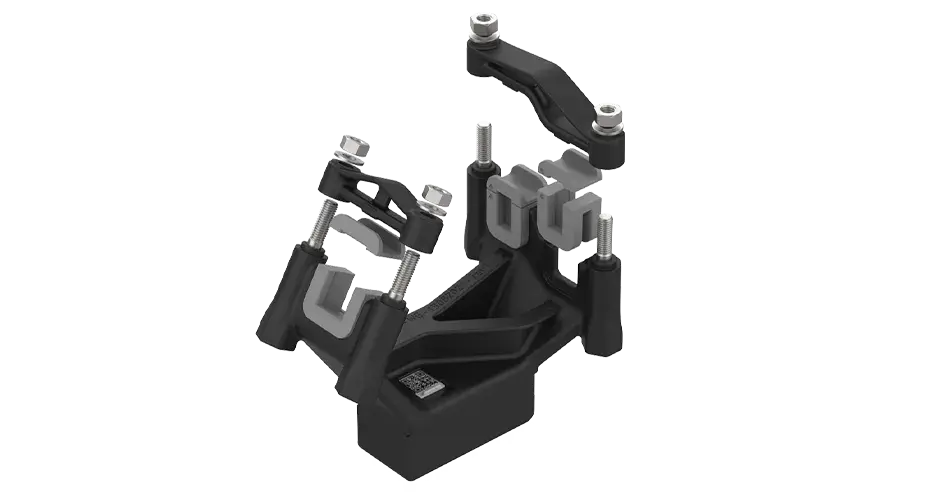

Modular CNC fixture that adjusts to 3D scan data of the final part.

Modular CNC fixture that adjusts to 3D scan data of the final part.

Fabrication, assembly and service processes can be complex, prone to quality issues

and unpredictable in terms of efficiency and time. Manufacturing aids are often used to reduce applied labor time and improve ergonomics and quality. To better achieve these targets they have become more and more complex and subject to frequent modifications.

Use our 3D printing solutions to flexibly print jigs, aids and tools on-site. Optimize fabrication, assembly, quality and service operations while improving ergonomics and controlling inventory costs — even in the most challenging environments. Tailor your devices to your specific processes and components and quickly iterate for continuous improvement without the expense of traditional tooling and inventory.

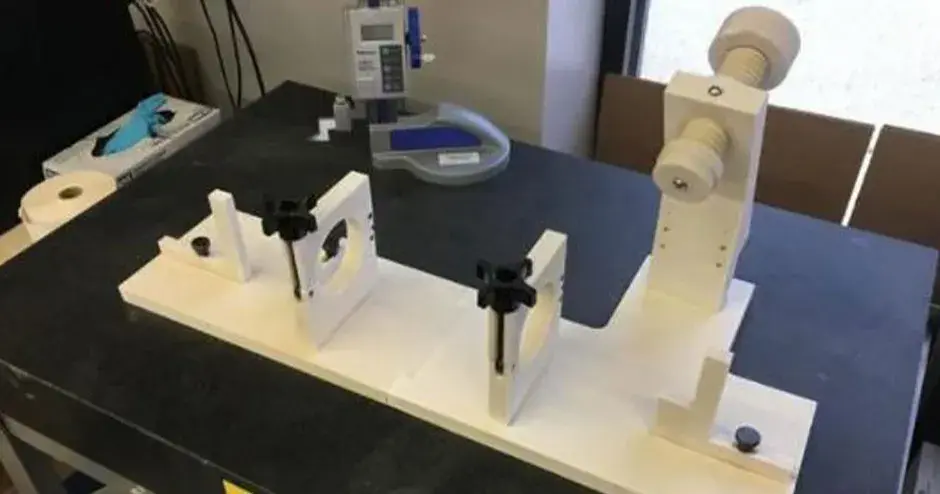

A flexible plastic gauge used to inspect production inserts printed using Figure 4 technology.

Efficiency in quality assurance relies on accurate and reliable inspection fixtures, jigs and gauges. Normal use and handling can distort these controls over time. Our advanced materials, 3D printing technologies and design practices help you adopt optimized solutions to implement more effective quality control and repeatable inspection processes to maximize productivity in your manufacturing operations.

New products frequently require new maintenance tool kits to ensure proper service and handling for maximum performance during the expected life of the vehicle and its equipment.

With 3D Systems’ additive manufacturing solutions you can design, validate and produce service kits faster and on demand to provide customer support teams with the right tools to meet their mission.

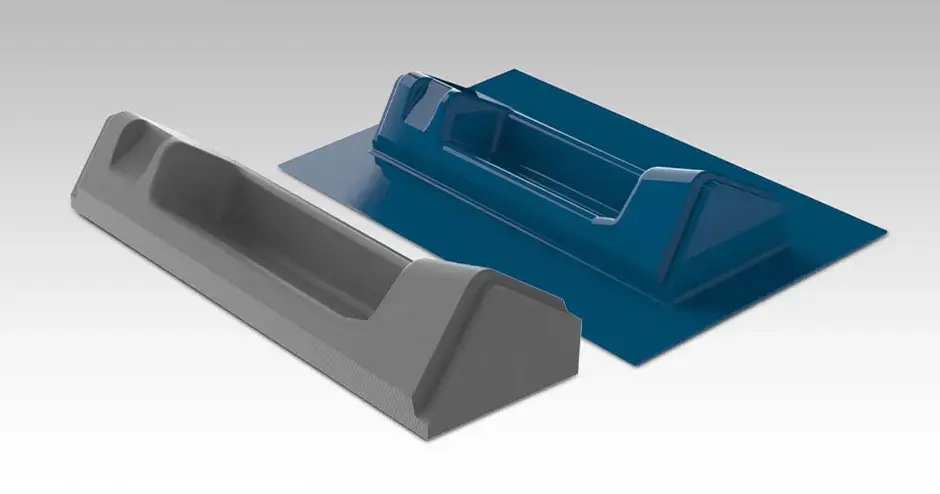

An interior train part produced using a 3D printed mold and conventional vacuum process.

Conventional tools and dies for thermoforming and hydroforming are expensive and can take a long time to manufacture. 3D Systems’ additive manufacturing solutions can meet your short-run production tooling needs faster and more cost-effectively with a broad variety of large printer sizes and tough FDM, SLA and SLS materials.

Get an insight into design for 3D printing jigs and fixtures, common geometries 3D printers can produce as well as technology and material considerations for your application requirements.

By using an additive manufacturing workflow, final welding fixture production time was reduced by 84% and fixture cost was reduced by 56%.

Ultra-tough grey plastic, replaces CNC-machined polypropelene and ABS

Broad selection of commercial, flexible, engineering grade and high-performance polymers for 3D printing

High temperature resistant translucent plastic with HDT over 300°C

Industrial-scale, process controlled additive manufacturing solution for selective laser sintering

Ultra-fast and affordable for same day prototyping and low-volume production