Traditional manufacturing methods often force engineers to make tradeoffs between tooling costs, part quality, and manufacturing lead times. Nevertheless, complex geometries that could improve these factors are either too difficult or too costly to implement.

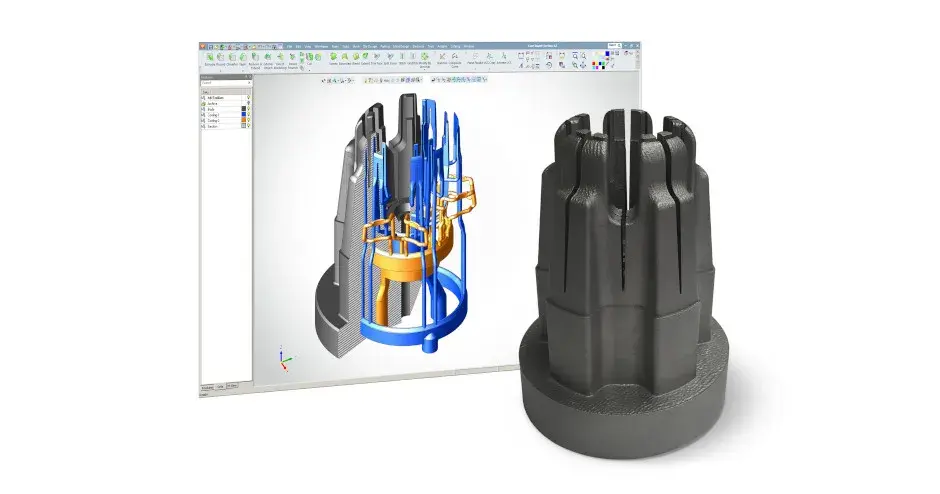

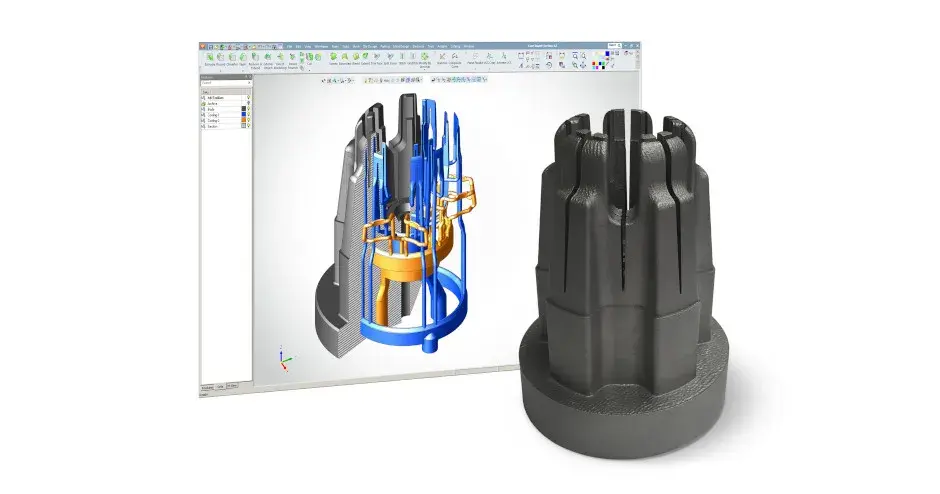

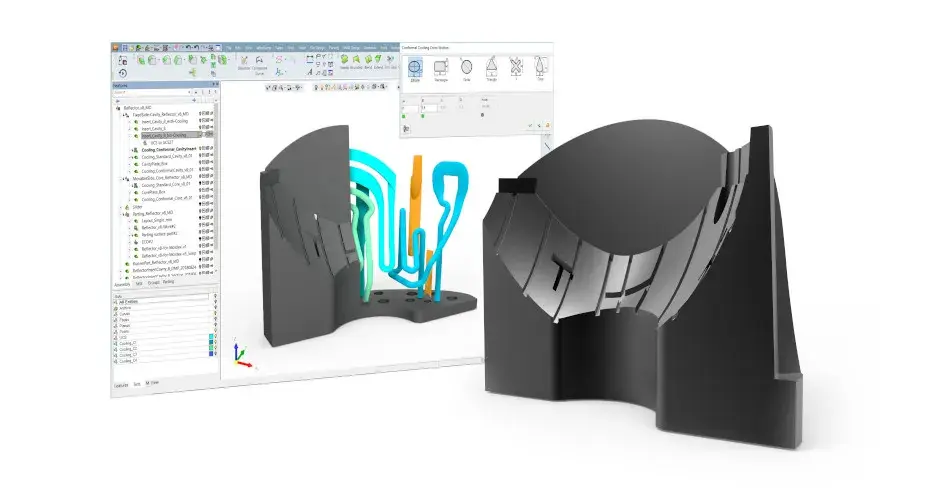

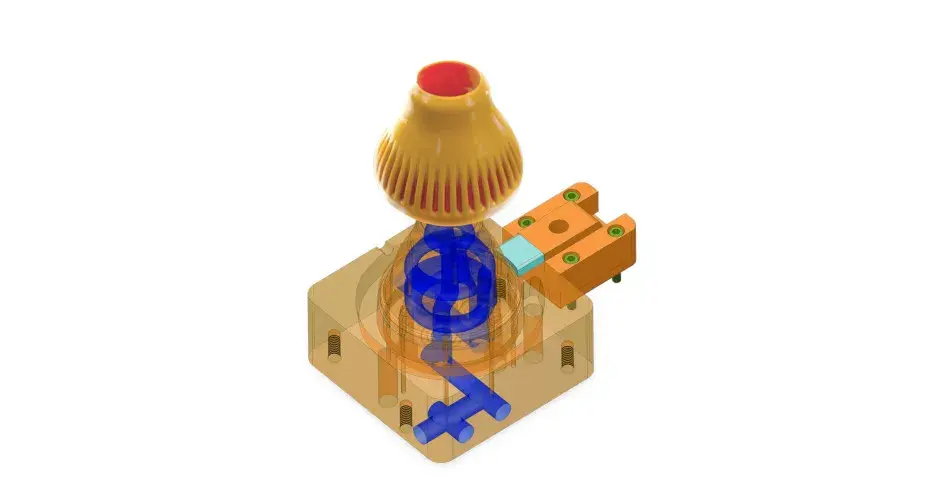

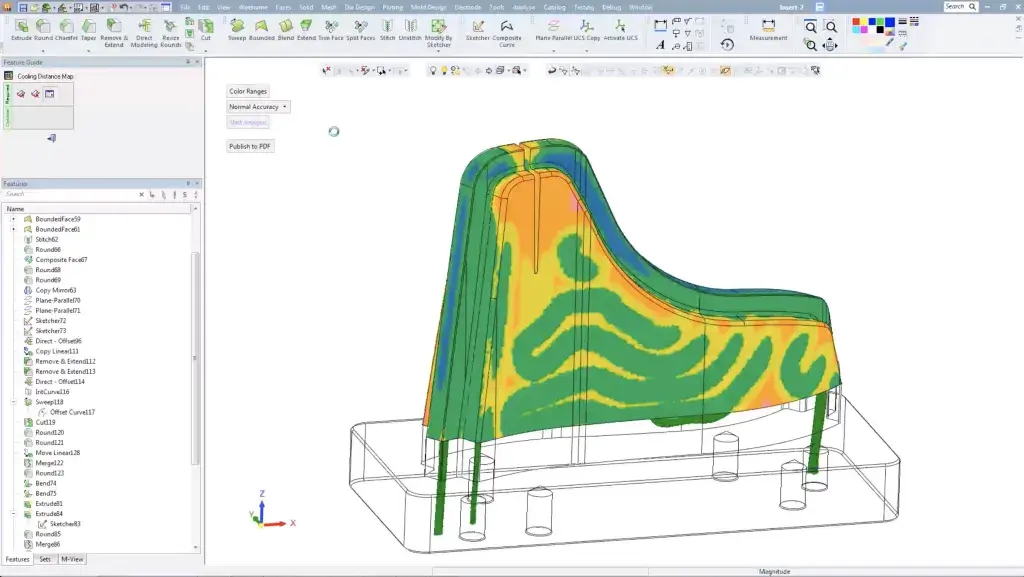

Our metal additive manufacturing solutions overcome this challenge with an innovative set of tools and processes for managing every aspect of metal durable tooling. The combination of comprehensive software solutions, exhaustive process knowledge, and advanced metal 3d printing equipment and materials technologies enable you to leverage complex die inserts, apply high productivity conformal cooling, produce precision jigs and fixtures and quickly iterate on complex tools like tire molds.

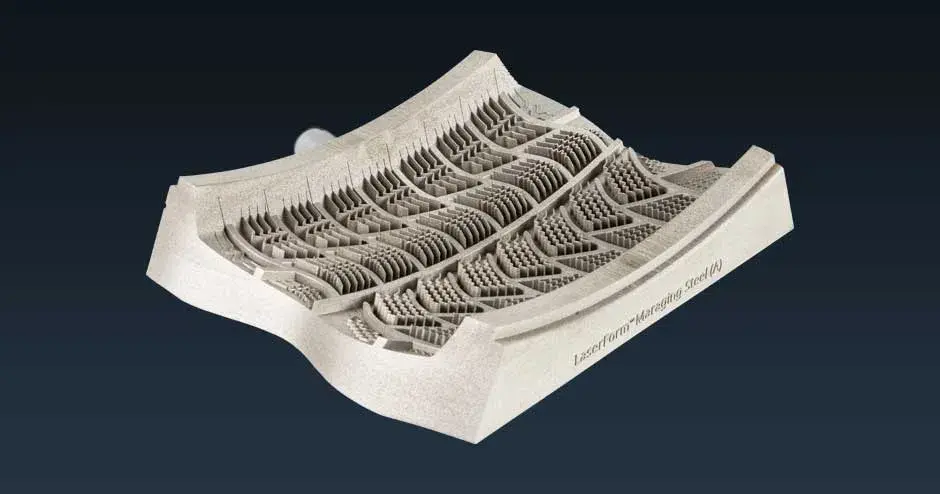

Produce high-strength, corrosion resistant, cobalt free molds and tools with NEW Certified M789 (A) metal AM material to manage heat dissipation, achieve uniform cooling, reduce warping and deformation to produce quality parts faster upon start-up, achieve better overall molding economics.

Cobalt free, high strength tool steel with excellent corrosion resistance

All-in-One Integrated Software for Industrial Additive Manufacturing