The last two years (2015 and 2016) could be looked upon as the tipping point for direct metal printing (DMP) within the aerospace industry, as the technology increasingly made the jump beyond prototyping to production parts and assemblies ready for flight.

During that time frame, Airbus Defence and Space worked with 3D Systems to achieve a major breakthrough: the first 3D printed radio frequency (RF) filter tested and validated for use in commercial telecommunications satellites. The project built upon research funded by the European Space Agency (A0/1-6776/11/NL/GLC: Modelling and Design of Optimised Waveguide Components Utilising 3D Manufacturing Techniques).

Metal RF or waveguide filters date back to the first space communication systems nearly 50 years ago. The filters act like traffic cops, allowing frequencies from selected channels to pass through and rejecting those from signals outside those channels.

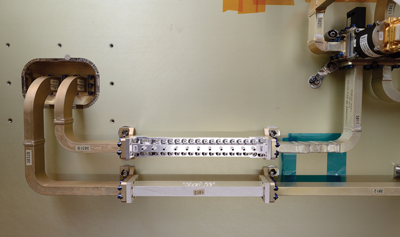

A major industry trend is to increase the capacity for multiple beams within a single satellite. A high-capacity satellite such as the Eutelstat KA-SAT manufactured by Airbus Defence and Space carries nearly 500 RF filters and more than 600 waveguides. Many of these are custom-designed to handle specific frequencies.

Meeting critical mandates

Telecommunications satellites exemplify the aerospace industry’s relentless emphasis on reducing weight — sending a vehicle into a geo-stationary orbit can cost as much as $20,000 per kilogram. Continuing design innovation and reduced production time are also major priorities, as most satellites are designed for a lifetime of 10–15 years.

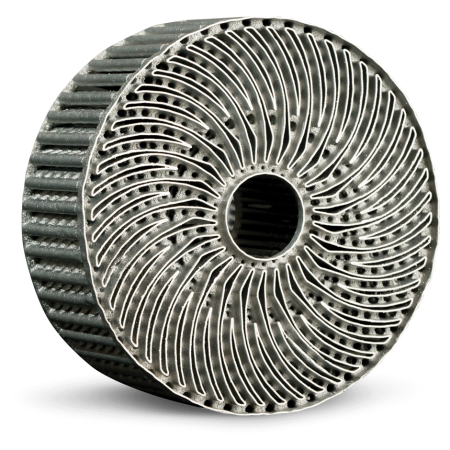

These priorities make telecommunications satellites the ideal candidate for direct metal printing. The 3D Systems ProX® DMP 320 used in the Airbus RF filter project enables manufacturers to consolidate parts, improve functionality with shapes and surfaces not possible to manufacture via traditional means, reduce production time and lower costs for customized designs, and decrease weight while maintaining or improving material strength.

New application for proven printer

3D Systems’ facility in Leuven, Belgium, has been using the 3D Systems ProX DMP 320 since the machine was in its beta stages. Successful projects include topological optimization, weight reduction and parts consolidation for spaceflight-validated parts such as brackets and strut end fittings for telecommunications satellites. The Airbus Defence and Space project was 3D Systems Leuven’s first foray into RF filters.

The ProX DMP 320 is designed to deliver high precision and high throughput in demanding 24/7 production environments. It’s broad range of LaserForm alloys (titaniums, stainless steels, aluminum, nickel chromiums and cobalt chrome) is formulated and fine-tuned for this metal printer to deliver high part quality and consistent properties.

Exchangeable manufacturing modules deliver increased applications versatility and less downtime when moving among different part materials. A controlled vacuum build chamber ensures that every part is printed with proven material properties, density and chemical purity.

Disruptive design innovation

The Airbus Defence and Space RF filter project demonstrates the ability of 3D printing to enable new design innovation for aerospace parts that haven’t changed appreciably in decades.

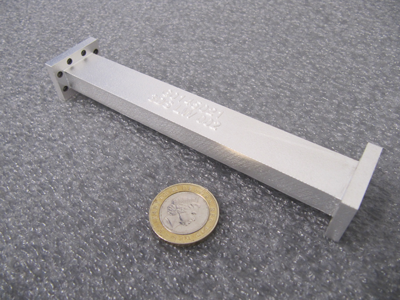

RF filters are traditionally designed based on libraries of standardized elements, such as rectangular cavities and waveguide cross-sections with perpendicular bends. Shapes and connections are dictated by typical manufacturing processes such as milling and spark eroding. As a result, cavities for RF filters typically need to be machined from two halves bolted together. This increases weight, adds an assembly step to production time, and requires extra

quality assessment.

Designing the parts for 3D printing enabled Airbus Defence and Space to explore complex geometries at no additional manufacturing cost.

CST MWS, a standard 3D electromagnetic simulation software tool, was used to design the 3D printed RF filters, with little time spent on optimization. The increased manufacturing flexibility enabled by 3D printing led to a design using a depressed super-ellipsoidal cavity. The unique shaping helped to channel RF currents and deliver the required tradeoffs between Q factor—a measure of a waveguide’s efficiency based on energy lost—and rejection of

out-of-band signals.

“The disruptive innovation lies in the fact that pure functionality, not manufacturability, now determines how the hardware will be designed,” says Koen Huybrechts, project engineer for 3D Systems in Leuven. “This project is a classic example of ‘form follows function’.”

“The main benefits of a monolithic design enabled by 3D printing are mass, cost and time,” says Paul Booth, the RF engineer for Airbus Defence and Space in Stevenage, United Kingdom. “The mass is reduced because there is no longer the requirement to have fasteners. With direct metal printing there is also the no-cost bonus to have the outer profile more closely follow the inner profile, so only the really necessary metal needs to be used. The cost/time benefit comes from the reduction in assembly and post-processing.”

Eliminating surface concerns

Initially, the different surface topology in 3D printed metal parts was thought to be an issue, but extensive testing by Airbus Defence and Space eliminated those concerns.

“The microscopic topology is different in the 3D printed part than in a machined part,” says Booth. “Machined surfaces have sharp peaks and troughs, while the 3D printed surface is spheroids melted together so there is less sharpness.”

“The spherical shape of the powder particles used in 3D metal printing lead to a certain waviness rather than steep transitions,” says Huybrechts, “but the ability to shape a part for more effective signal filtering more than overcomes any concerns with surface topology.”

“We were very pleased with the work that 3D Systems did for us and many inside Airbus have commented on how good the surface finish is,” says Booth. “We did some x-ray CT scans and have been impressed with the density of the part and the general surface quality.”

Passing rigorous tests

Three aluminum samples printed on the ProX DMP 320 using different processing paths were tested by Airbus Defence and Space at its Stevenage facilities. Tests mimicked conditions the parts would face during launch and orbit, including vibration, shock and thermal situations such as temperature extremes and vacuum conditions. All three samples met or exceeded requirements, with the best performance coming from a filter that was silver-plated via an electrolytic process.

Beyond 3D printing, 3D Systems delivered added value that is critical to this kind of project, including certified powder handling, process control for superior material density, proven post-processing, and reliable quality control.

Booth recognizes that this added expertise played a key role in the project’s success: “We realize that this is not just down to using a good machine to manufacture the part but also the result of a good understanding by 3D Systems of the manufacturing process.”

Massive ROI potential

Now that the process has been validated and the parts have met the highest spaceflight standards Airbus Defence and Space has in place, the company can begin to consider the return on investment potential for 3D metal printing. The project delivered the kind of ROI that puts a glimmer in a CFO’s eyes: faster turnaround time, reduced production costs and a stunning weight reduction of 50 percent.

“Mass was reduced without spending any time on optimization,” says Booth, “and it can be reduced further with more aggressive mechanical design. The reduced mass saves costs by requiring less propellant in the rocket and puts fewer demands on support structures, allowing further mass reduction.

“The success of this project opens up the possibility of much greater integration of RF filters with mechanical and thermal components to reduce part count and overall mass. We will also look at integrating more functionality such as test-couplers as part of the filter or directly integrated into waveguide runs. There is a huge potential for reducing mass while cutting production time and costs.”