Why DMP Flex 350?

DMP Flex 350 Specifications

| DMP Flex 350 Tech Specs | |

|---|---|

| Laser Power Type | DMP Flex 350: 500W/Fiber laser1 |

| Laser Wavelength | 1070 nm |

| Single Build Volume (X x Y x Z) Height inclusive of build plate | 275 x 275 x 420 mm (10.82 x 10.82 x 16.54 ) |

| Layer Thickness | Adjustable, minimum 5 μm, typical values: 30, 60, 90 μm |

| Metal alloy options for dual laser configurations: | LaserForm Ti Gr1 (A)², LaserForm Ti Gr5 (A)², LaserForm Ti Gr23 (A)², Certified Tungsten (A)², Certified A6061-Ram2 (A)3, Certified CuNi30 (A)3, LaserForm AlSi10Mg (A)3, LaserForm AlSi7Mg0.6 (A)3, LaserForm Ni625 (A)³, LaserForm Ni718 (A)³, LaserForm 17-4PH (A)³, LaserForm 316L (A)³, LaserForm CoCrF75 (A)³, LaserForm Maraging Steel (A)³, Certified Scalmalloy (A)3, Certified M789 (A)3, Certified HX (A)³, Certified CuCr2.4 (A), Certified GRCop-42 (A)³, Certified CuCr1Zr (A)³, Certified C-103 (A)³, *GRX-810³ |

| Material Deposition | Soft blade recoater |

| Repeatability | Δx (3σ) = 60um, Δy (3σ) = 60um, Δz (3σ) = 60um |

| Minimum Feature Size | 200 μm |

| Typical Accuracy | ± 0.1-0.2% with ± 100 μm minimum |

| Build Platform Heating | 250°C |

3DXpert: Industry leading software for Additive Manufacturing

Fully Integrated - Single Environment

3DXpert is your one-stop-shop for additive manufacturing. Streamline your workflow, maximize efficiency, and avoid costly errors, by completing all AM processes in the same software environment, including DfAM, build preparation, simulation, and inspection.

Achieve up to 75% faster file processing time with CAD to Slice workflows. No more compromising data integrity of mechanically designed parts to STLs. 3DXpert is built on a CAD engine - making history-based, parametric build preparation the new standard in AM. Hybrid DfAM combines the power of solid, mesh, and implicit (voxel-based) modeling.

3DXpert can help you handle any challenge AM throws at you. When faced with repetitive tasks, or part types that re-occur in your trays, 3DXpert can carry a lot of your load for you. By capturing your knowledge into scripts and using AI to group similar parts together and apply solutions to them, you are free to focus on more value-added tasks. Learn More

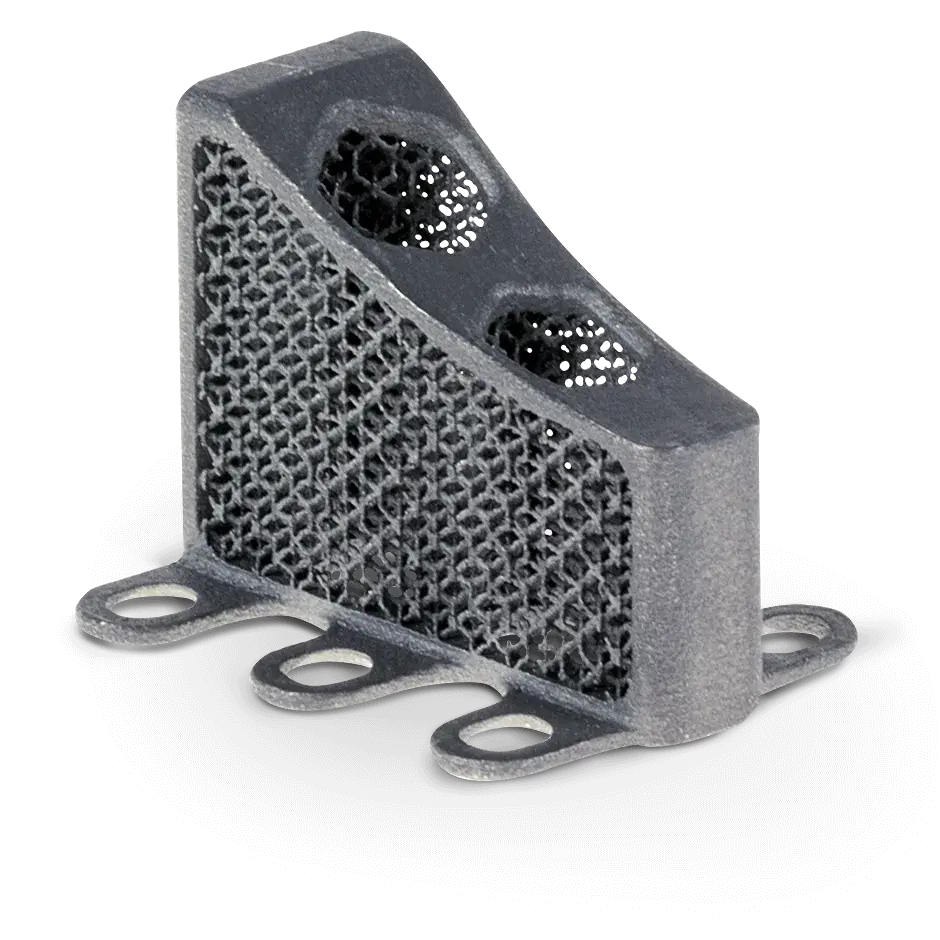

NoSupports

DMP Flex 350 Triple is NoSupports technology compatible. NoSupports enables metal powder-bed printing without support structures which accelerates production and delivery. Learn More

Volume Reducer Module

This module allows you to maximize your investment through enabling you to print small research parts and also maintain production capabilities with the same printer. Requiring only one tenth of the powder, you no longer need to be restricted in experimenting with exotic alloys! Learn more

DMP Inspection

DMP Inspection allows you to minimize secondary inspection with validated automated analysis. Take corrective action before you print! Our algorithms detect:

- Lack of fusion

- Warpage

- Down-facing surface roughness

- Recoating quality

DMP Monitoring

DMP Monitoring is real-time process monitoring for informed decisions on product quality. Achieve higher quality ouput with synchronized side-by-side comparison of the meltpool and vision data. Learn more

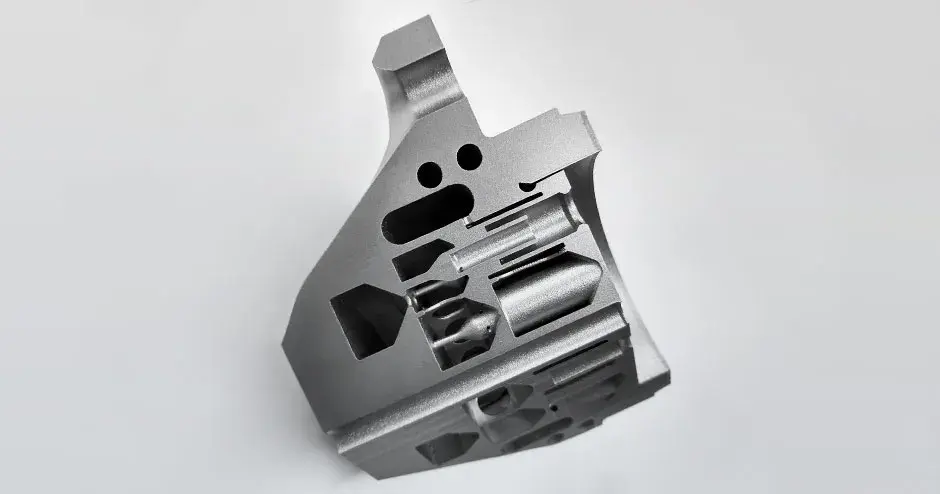

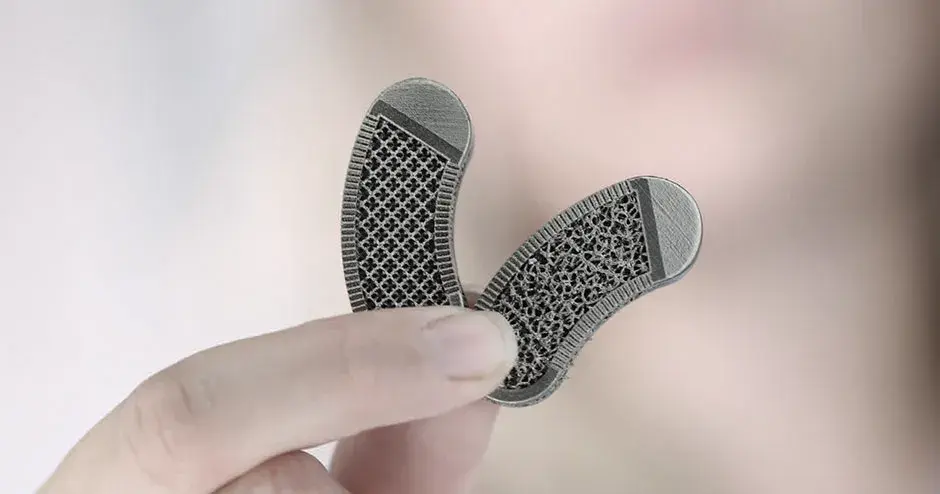

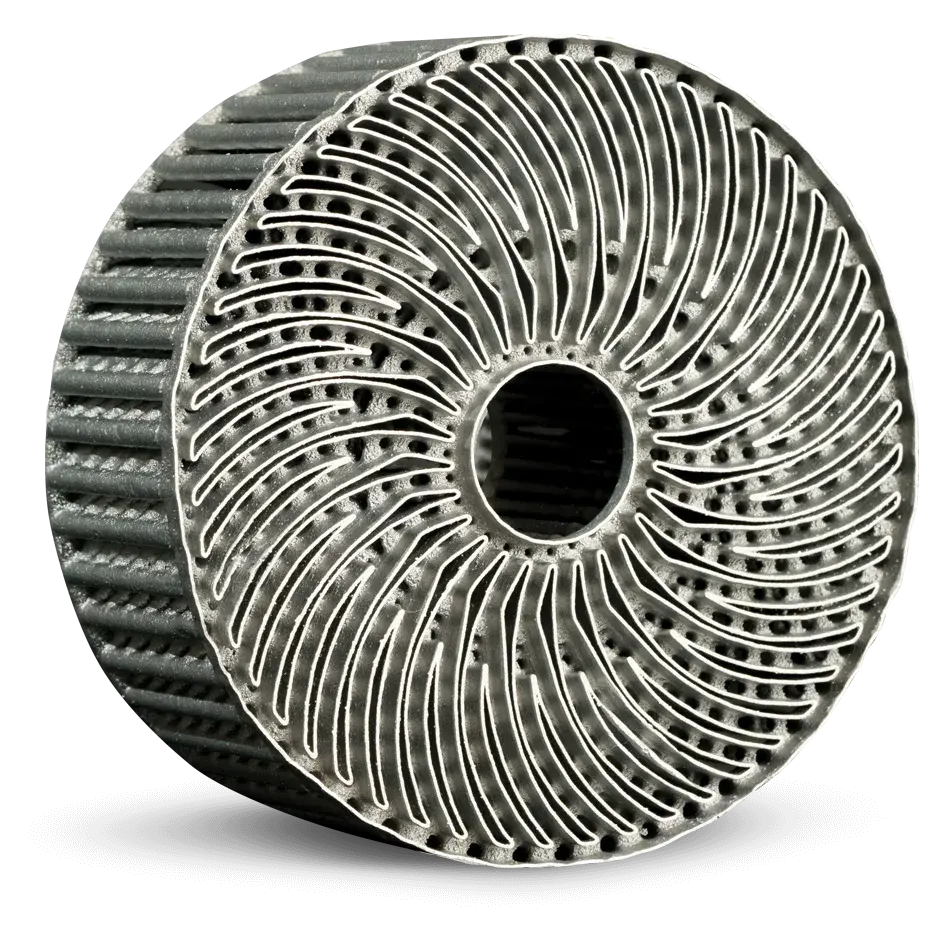

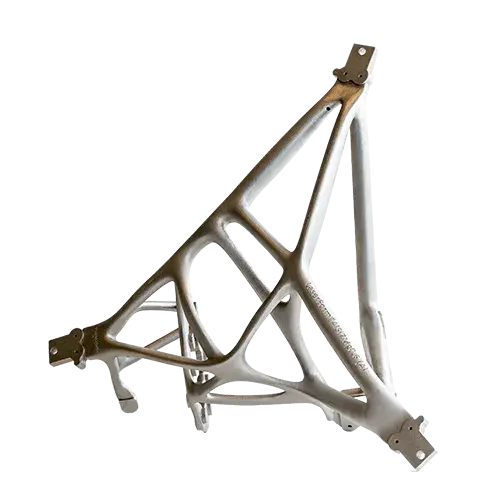

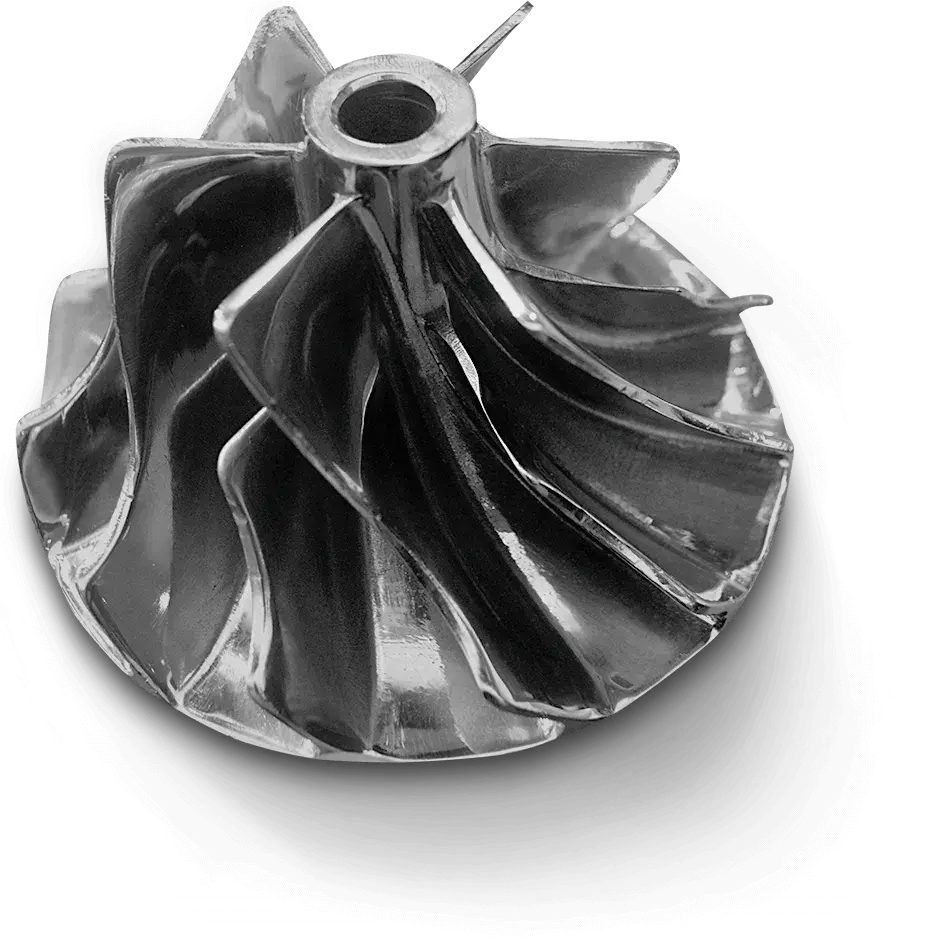

Ideal Applications for DMP Flex 350

Commonly Used Materials for the DMP Flex 350 Printer

LaserForm Ti Gr1 (A)

Light weight, biocompatible, extreme temperature and corrosion resistance

LaserForm Ti Gr5 (A)

High strength, low weight, excellent biocompatibility

LaserForm AlSi10Mg (A)

Good mechanical properties and good thermal conductivity

LaserForm AlSi7Mg0.6 (A)

Light weight, good mechanical properties and improved thermal conductivity

LaserForm Ni625 (A)

Excellent corrosion resistance, high strength and heat resistance

LaserForm Ni718 (A)

Oxidation, corrosion and extremely high-temperature resistant

LaserForm 17-4PH (A)

Excellent corrosion resistance, high strength with good toughness

LaserForm 316L (A)

Able to be sterilized and highly corrosion resistant.

LaserForm CoCrF75 (A)

Highly corrosion, wear and heat resistant. Bio-compatible.

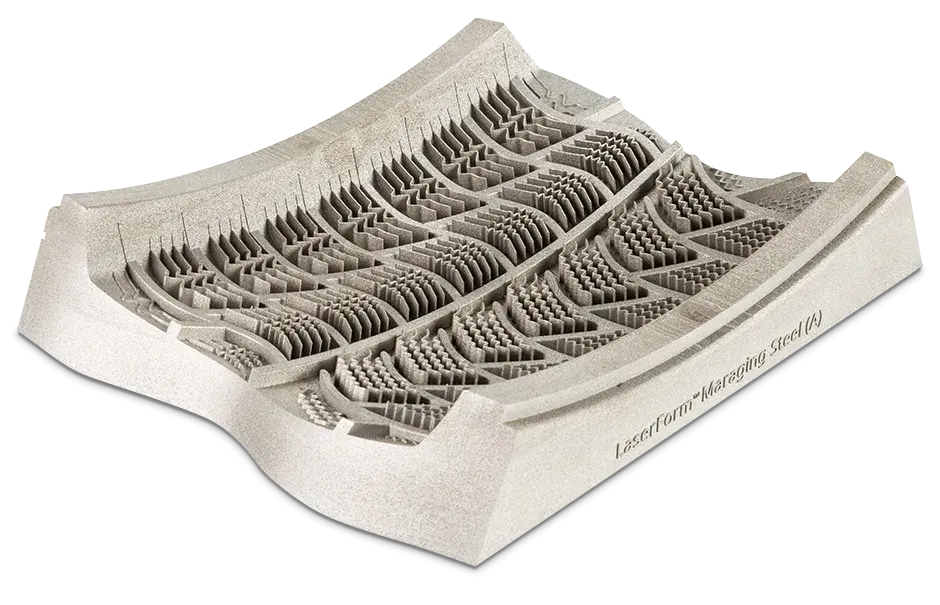

LaserForm Maraging Steel (A)

Excellent hardness and strength, good wear resistance.

Certified Scalmalloy (A)

High strength aluminum with excellent corrosion resistance

Certified M789 (A)

Cobalt free, high strength tool steel with excellent corrosion resistance

Interested in purchasing this printer?

You Might Also Be Interested In

DMP Flex 350 Dual

Midsize dual laser designed for application development, R&D, and production

DMP Flex 350 Triple

Midsize 3-Laser workhorse for reliable, repeatable production

DMP Factory 350

Midsize single laser designed for application development, R&D, and production

DMP Factory 350 Dual

Midsize dual laser designed for application development, R&D, and production