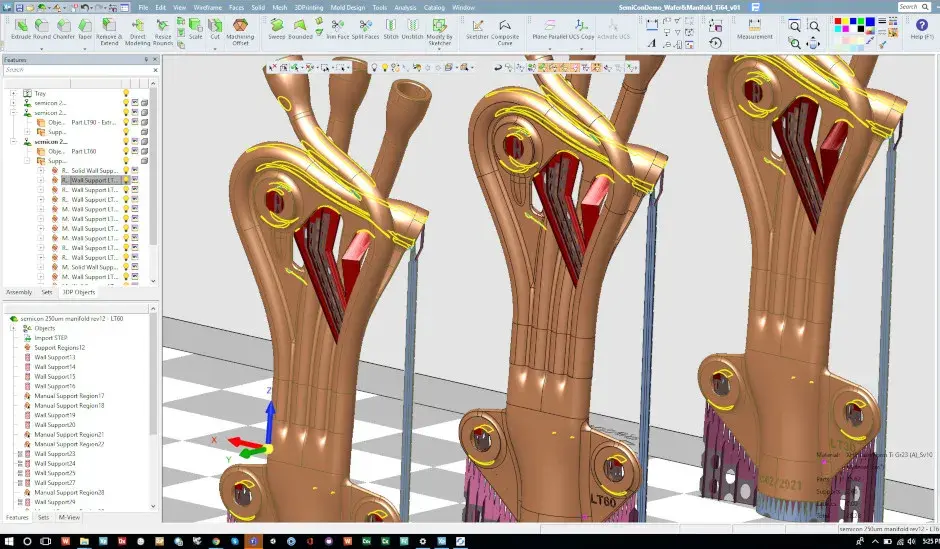

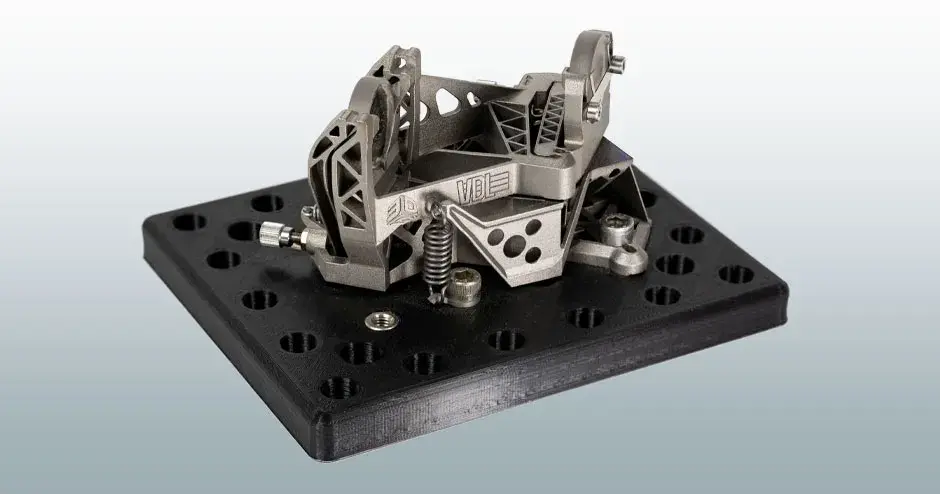

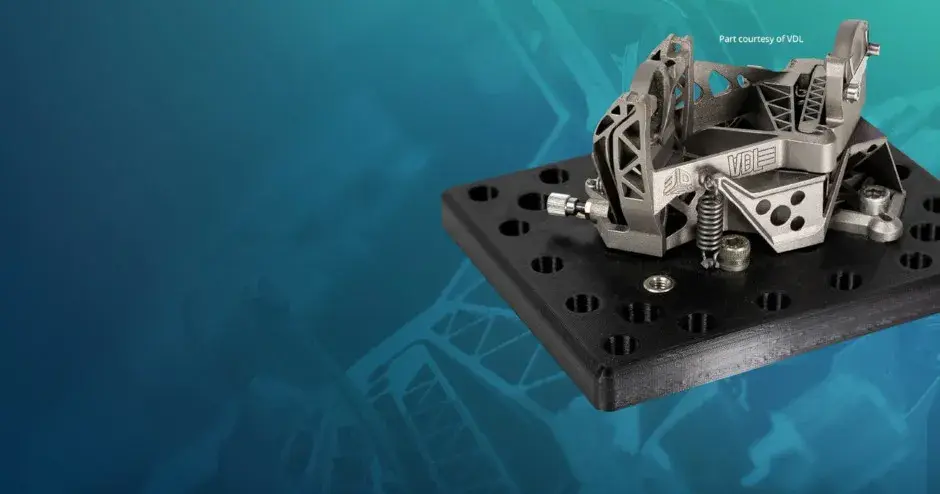

Part courtesy of VDL

Part courtesy of VDL

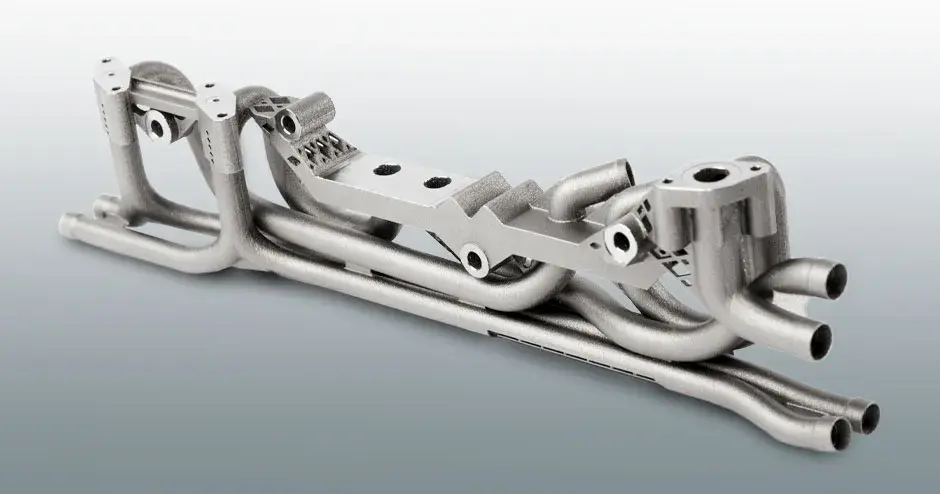

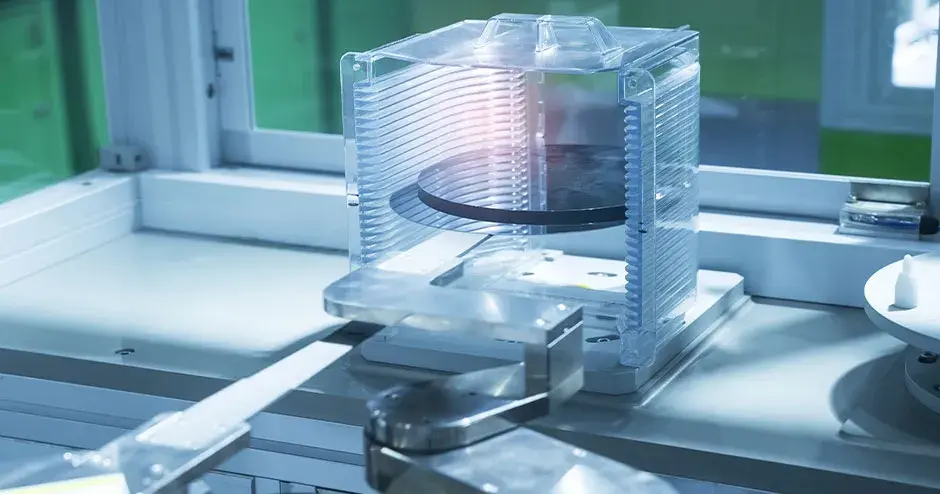

Additive manufacturing allows for the structural optimization and light-weighting of advanced flexure designs that reduce weight and minimize vibration to meet the exacting requirements of semiconductor capital equipment. Additionally, multipart assemblies can be replaced with monolithic parts for increased reliability, improved manufacturing, and yield.

With years of application engineering experience in the semiconductor industry, we can help you optimize the structural designs of flexures, advanced motion mechanisms, and components. Additive manufacturing gives designers the flexibility to optimize the structural topology of your part (i.e., lightweighting) with a suite of high-strength metal alloys. These designs can meet the performance requirements of semiconductor capital equipment more precisely, improve the strength-to-weight ratio, and deliver a faster time to market. With our metal additive solutions, you can also avoid traditional complex manufacturing assembly by consolidating several parts into one, which improves yield and reliability and reduces labor and inspection costs.

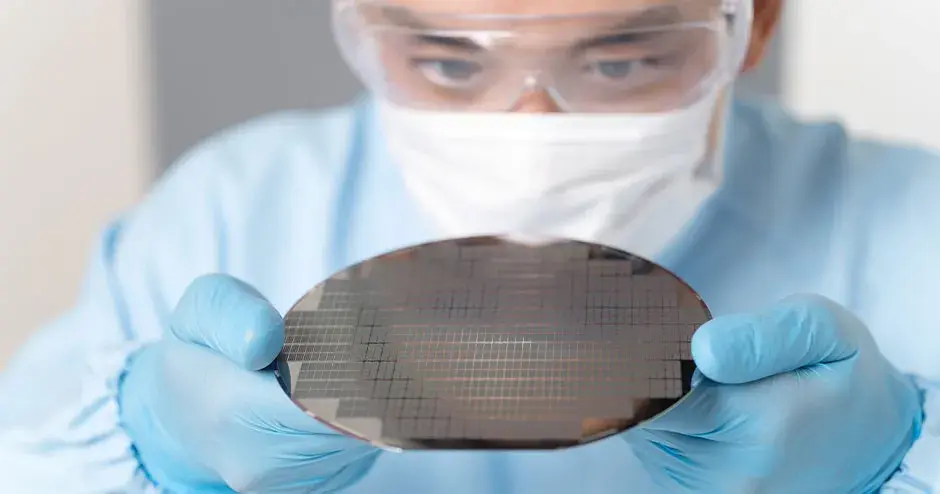

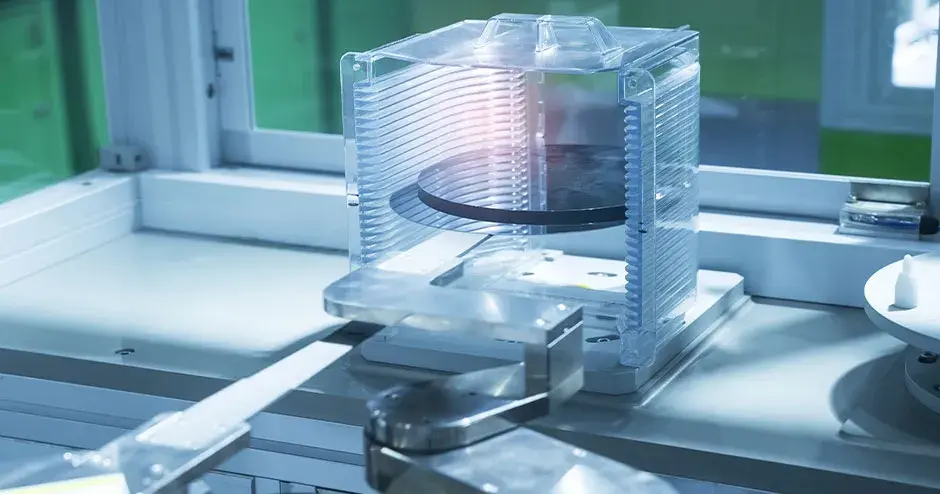

Semiconductor capital equipment features fast-moving mechanisms and components, and unnecessary weight can induce vibration, resonance, and inertia into the system, which negatively affects system accuracy and speed.

Reducing flexure weight and vibration requires designs with optimal strength-to-weight ratios to deliver exceptional system performance.

Part courtesy of VDL

Conventional flexures can be bulky and still deviate from the ideal kinematics, resulting in accuracy deviations and crosstalk.

Part courtesy of VDL

Adding flexures within brackets can help precision systems attain peak accuracy. Discover how additive manufacturing makes producing flexures attainable, along with a clear explanation of the flexure manufacturing workflow and best practices.

In this eBook, you’ll learn how 3D Systems’ decades of experience and expertise helps integrate metal AM to drive performance, productivity, and reliability improvements for semiconductor capital equipment manufacturers and suppliers.

Discover how 3D Systems’ metal additive manufacturing can give semiconductor capital equipment manufacturers and suppliers the capabilities they need to improve performance, productivity, and reliability.

High strength, low weight, excellent biocompatibility

All-in-One Integrated Software for Industrial Additive Manufacturing

Robust, high quality metal AM with integrated powder management

High strength, low weight, excellent biocompatibility - lower Oxygen than Gr5

Oxidation, corrosion and extremely high-temperature resistant

Excellent corrosion resistance, high strength and heat resistance

Good mechanical properties and good thermal conductivity

Light weight, good mechanical properties and improved thermal conductivity

High strength aluminum with excellent corrosion resistance

Able to be sterilized and highly corrosion resistant.

Real-time process monitoring for informed decisions on product quality