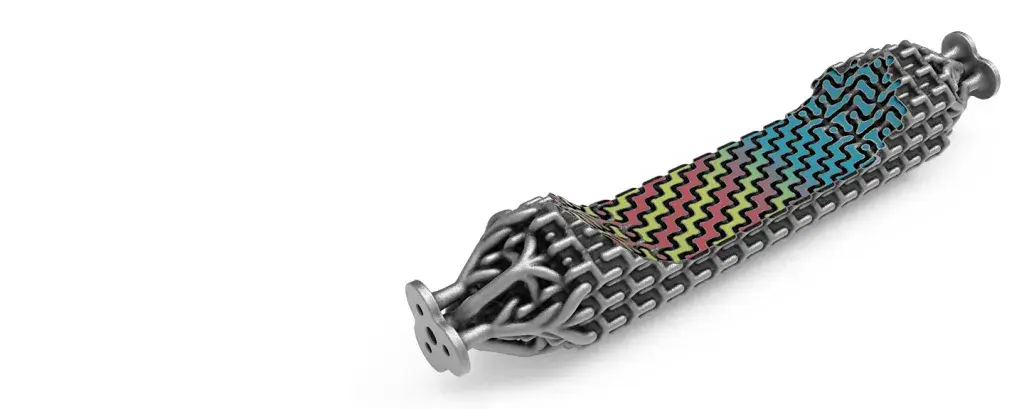

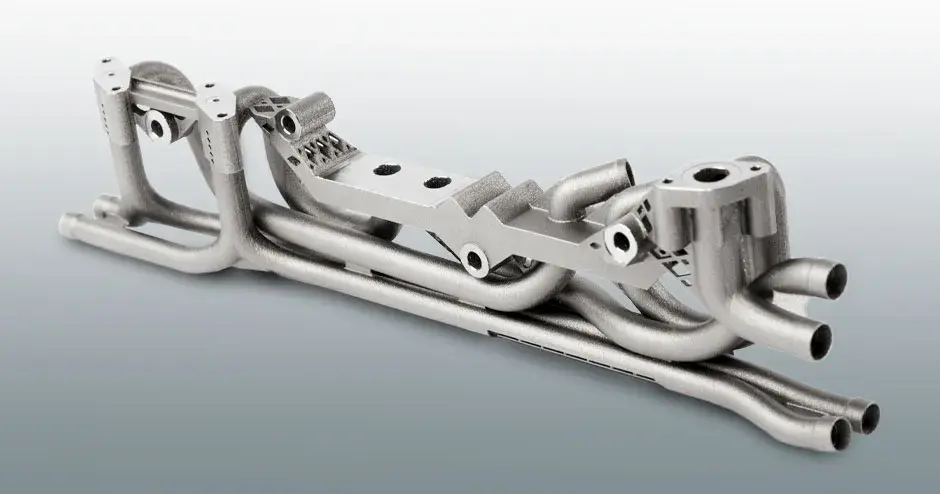

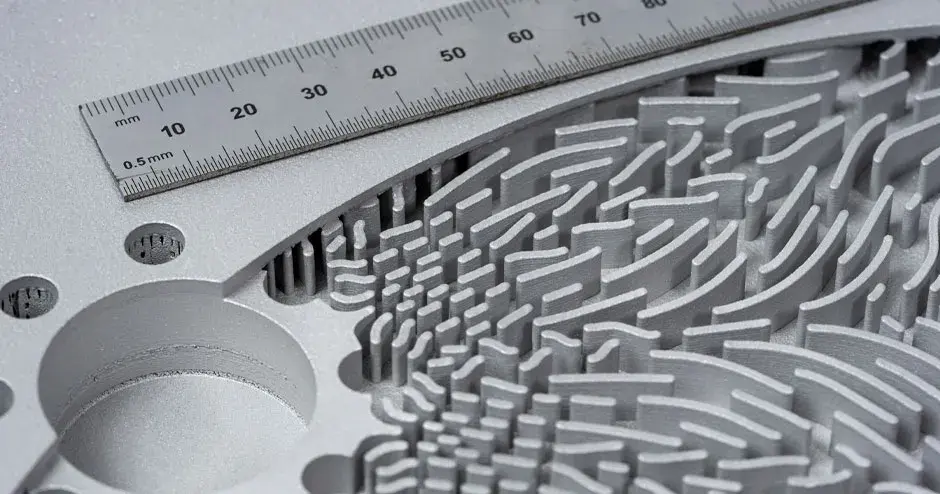

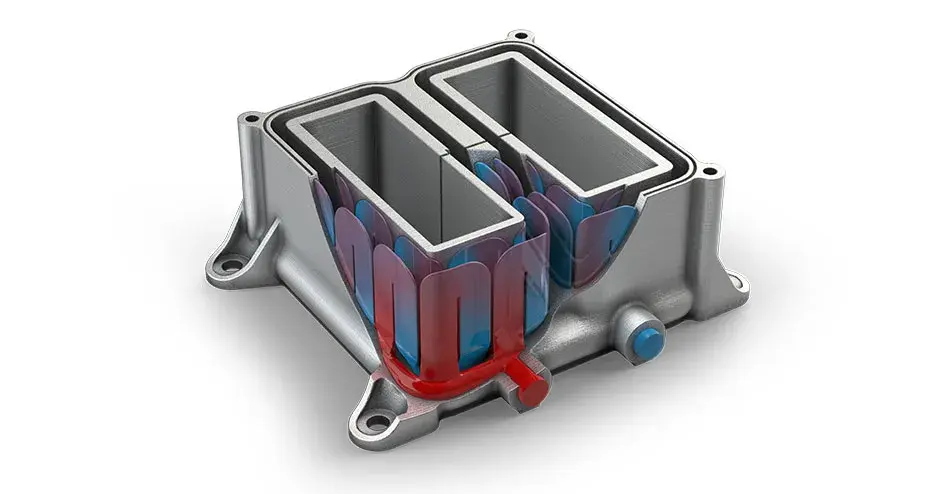

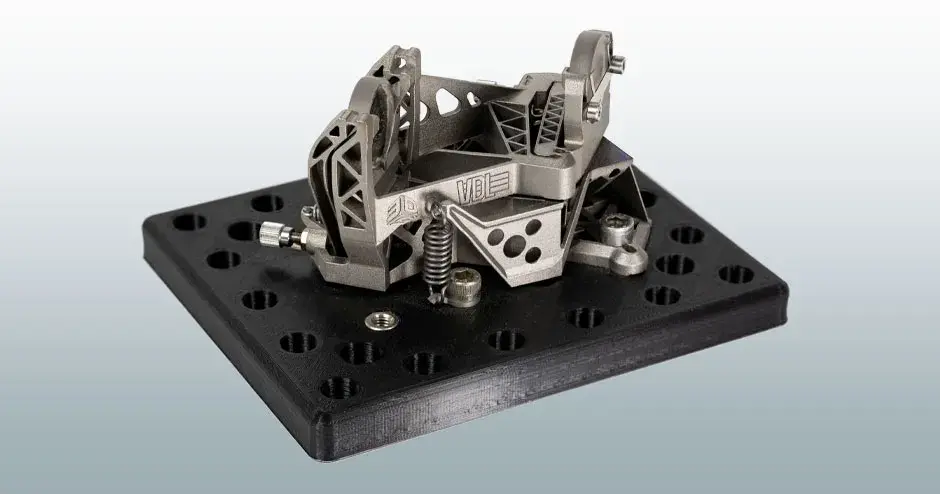

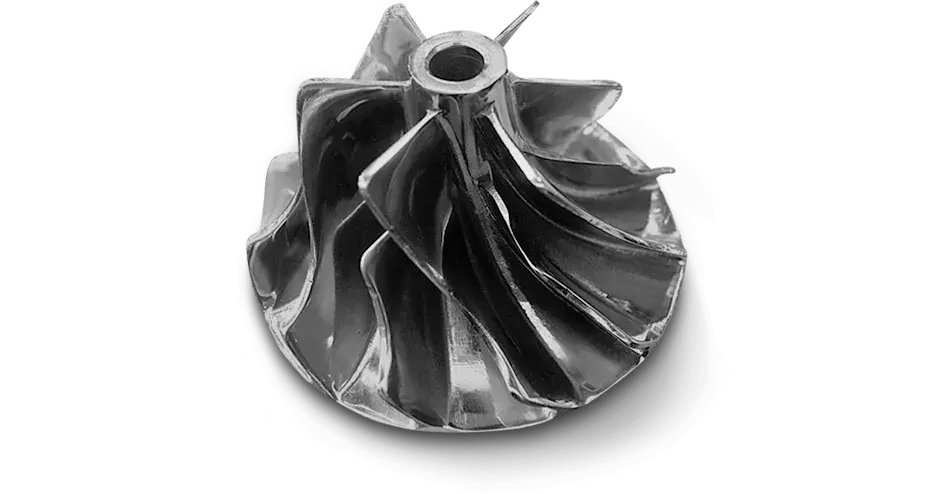

Improve Product Performance and Mixing Efficiency, Increase Reliability, and Reduce Manufacturing Costs by Leveraging Direct Metal Printing to Produce with Optimized Form Factors and More Efficient Gas Pathways

20:1

component reduction

100%

leak-proof

3x

more efficient

Reduce Part Count While Improving Gas Conveyance and Mixing Efficiency

The Benefits of Metal Additive Manufacturing

Optimizing Gas Conveyance and Mixing

Resources

More Semiconductor Applications

Learn More About Gas Conveyor and Mixer Manufacturing Solutions

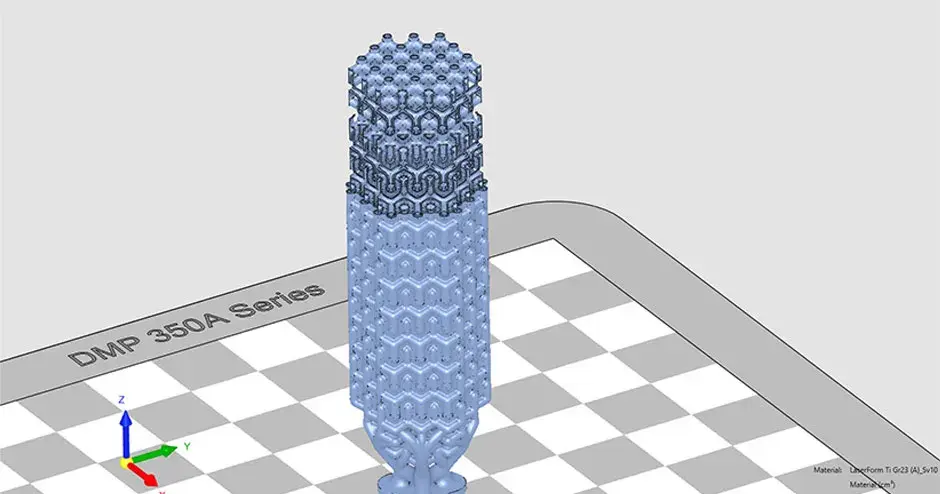

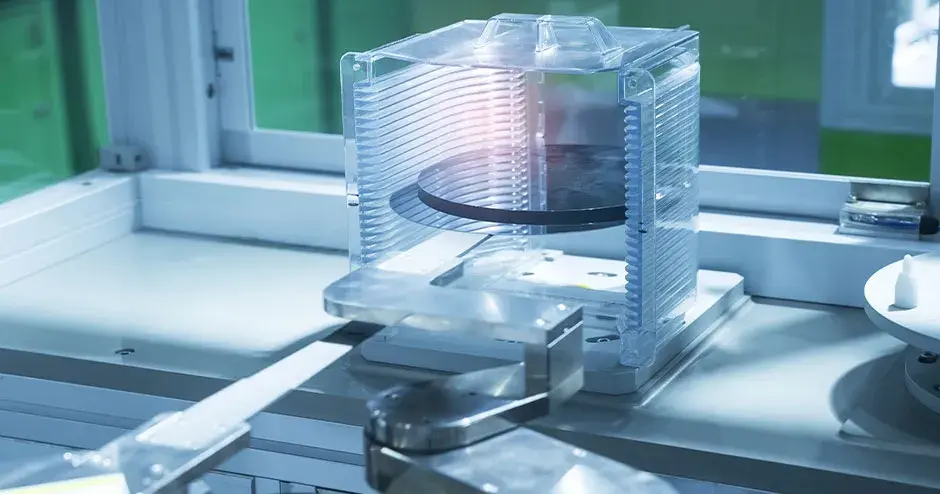

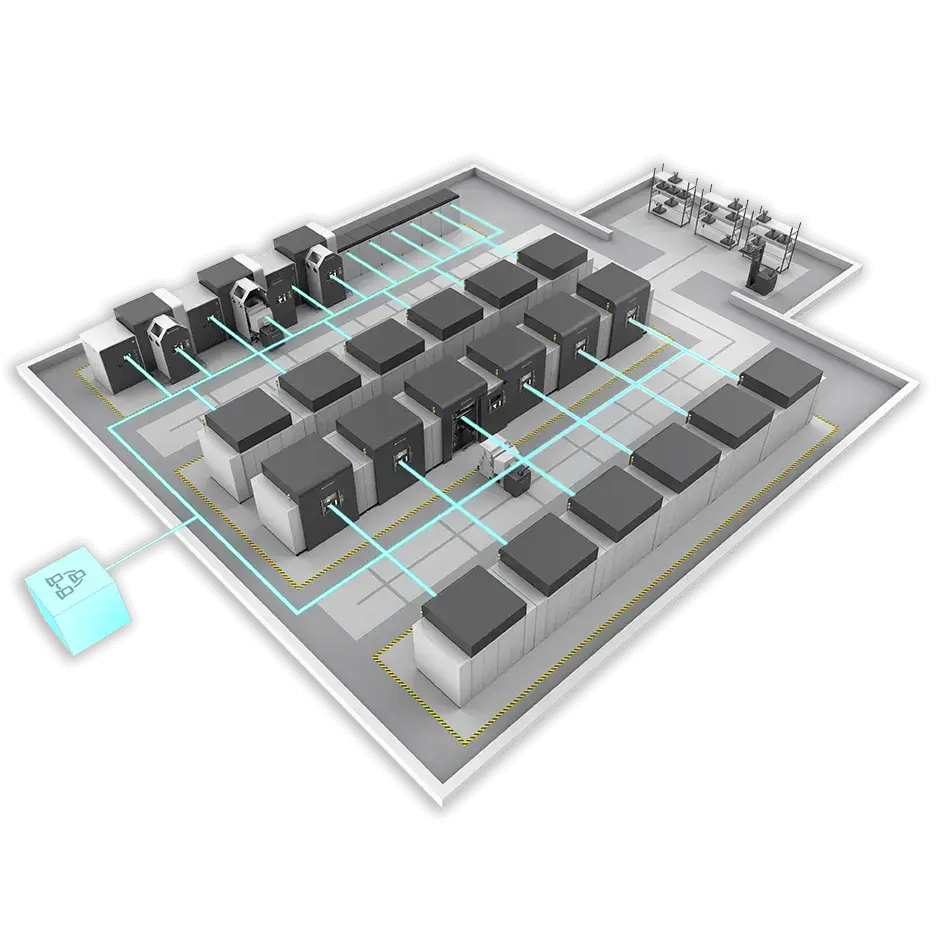

DMP Factory 500

Robust, high quality metal AM with integrated powder management

LaserForm Ni718 (A)

Oxidation, corrosion and extremely high-temperature resistant

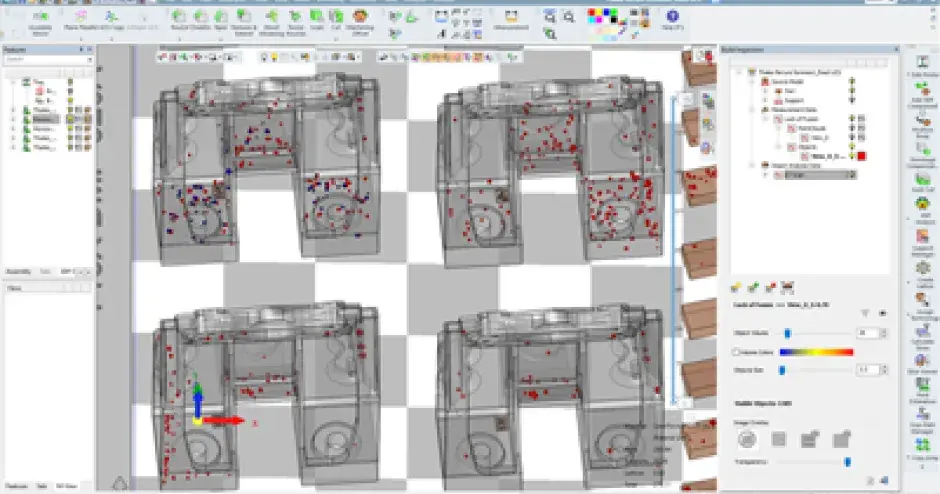

3DXpert

All-in-One Integrated Software for Industrial Additive Manufacturing

LaserForm 316L (A)

Able to be sterilized and highly corrosion resistant.

LaserForm AlSi10Mg (A)

Good mechanical properties and good thermal conductivity

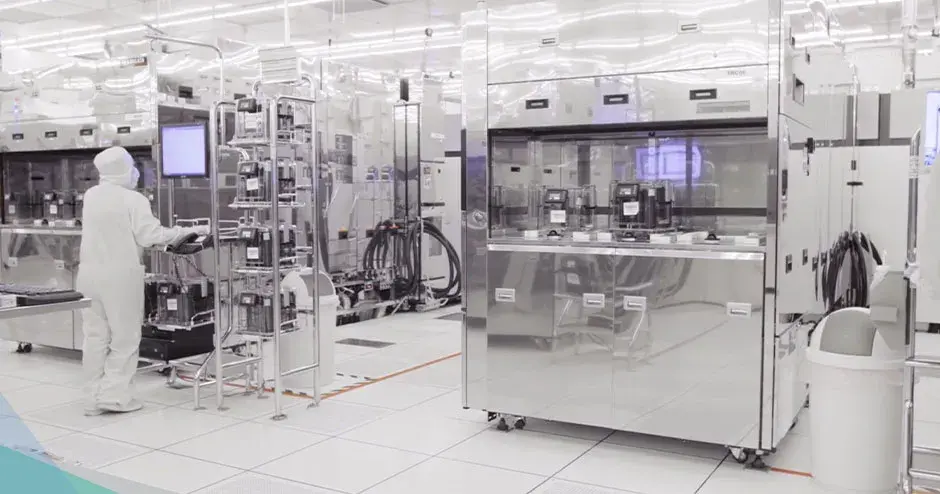

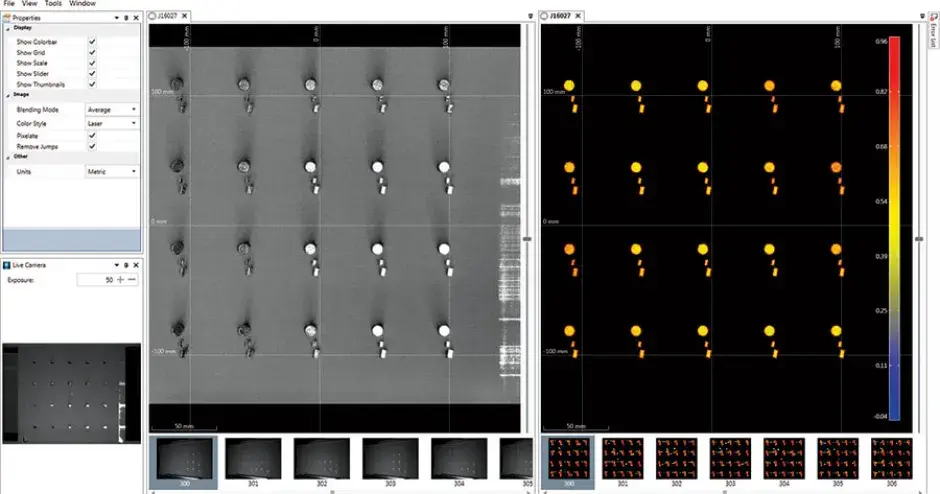

DMP Inspection

Minimize secondary inspection in Metal AM with validated automated analysis

DMP Monitoring

Real-time process monitoring for informed decisions on product quality