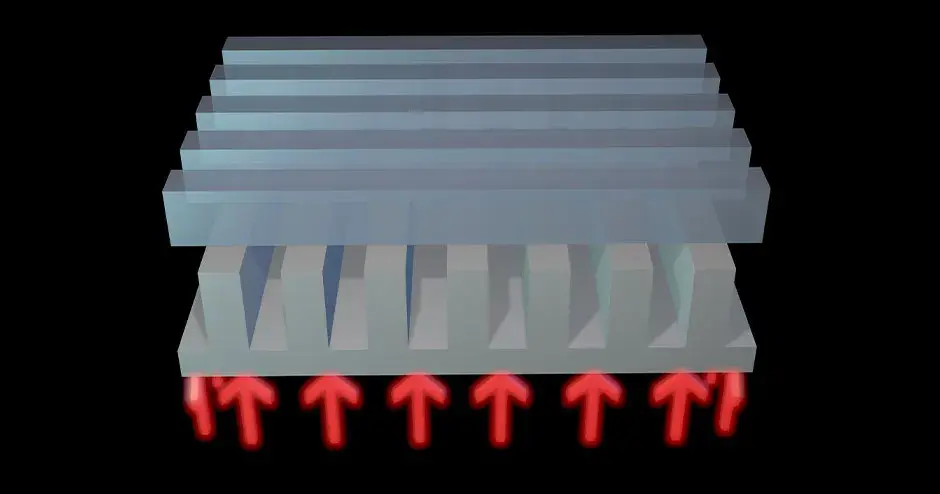

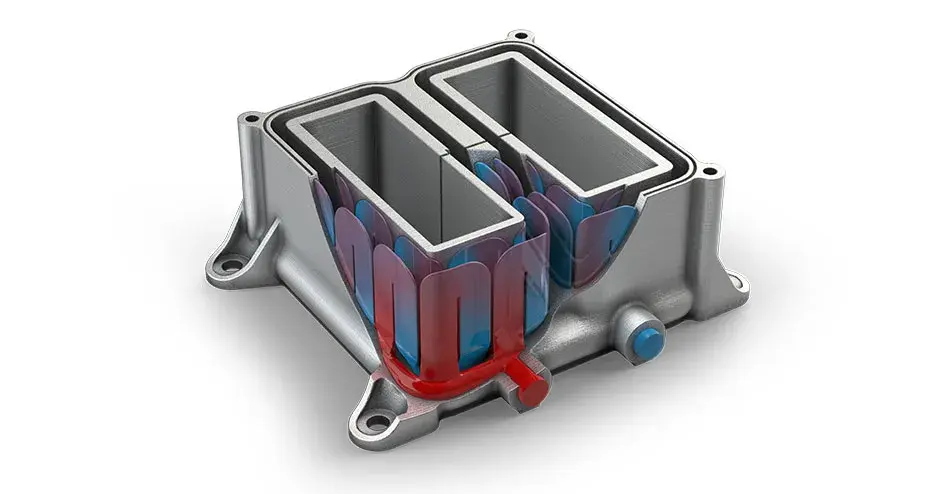

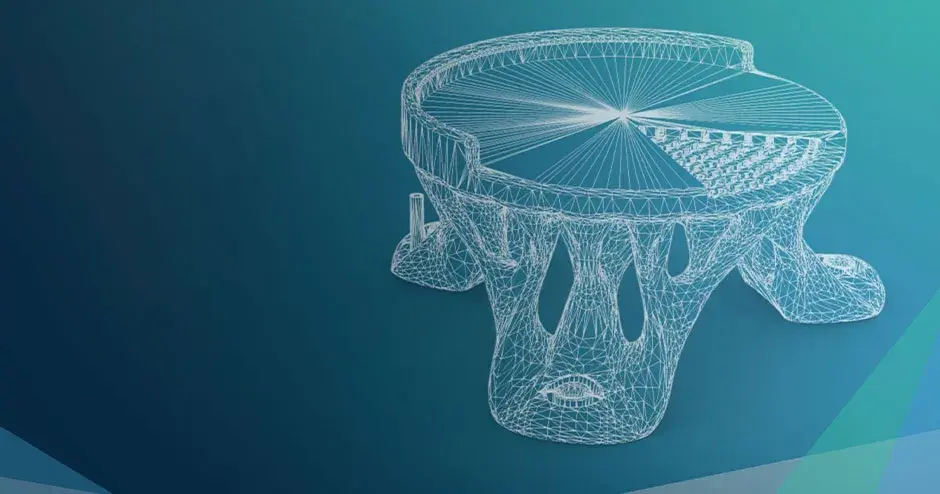

Improve Surface Temperatures and Thermal Gradients, while Reducing Time Constraints

83%

decrease in ΔT demonstrated (13.8 to 2.3 mK)

5x

stabilization improvement demonstrated

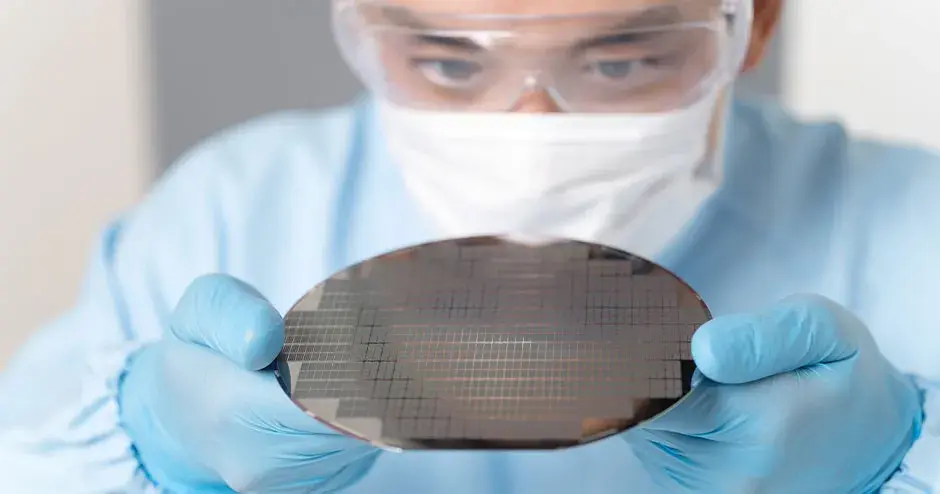

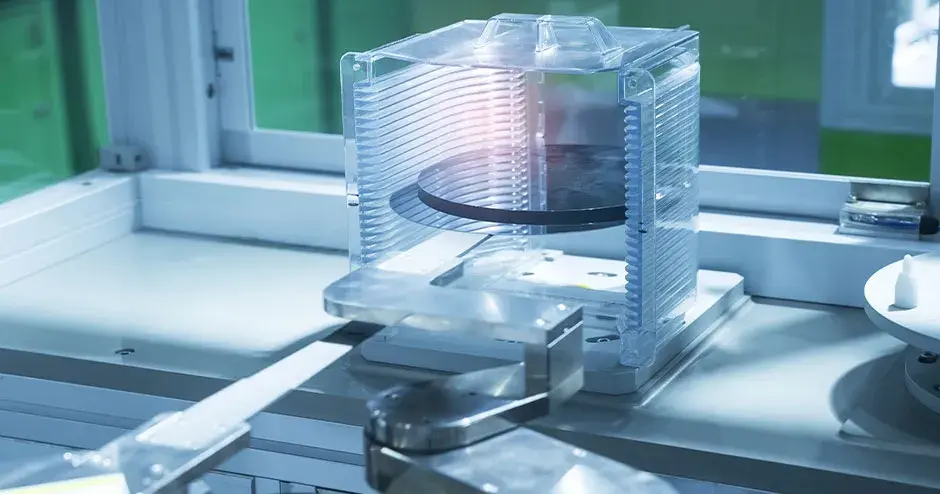

Optimize the Thermal Management of Semiconductor Equipment

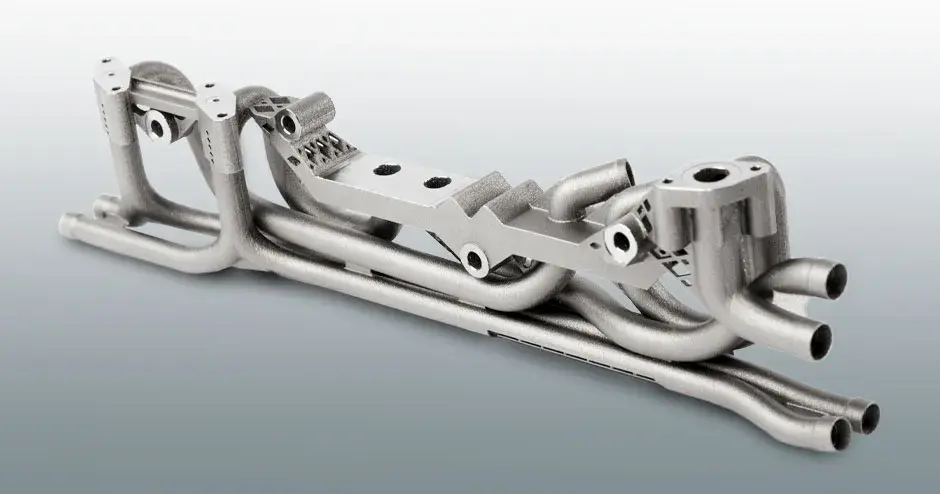

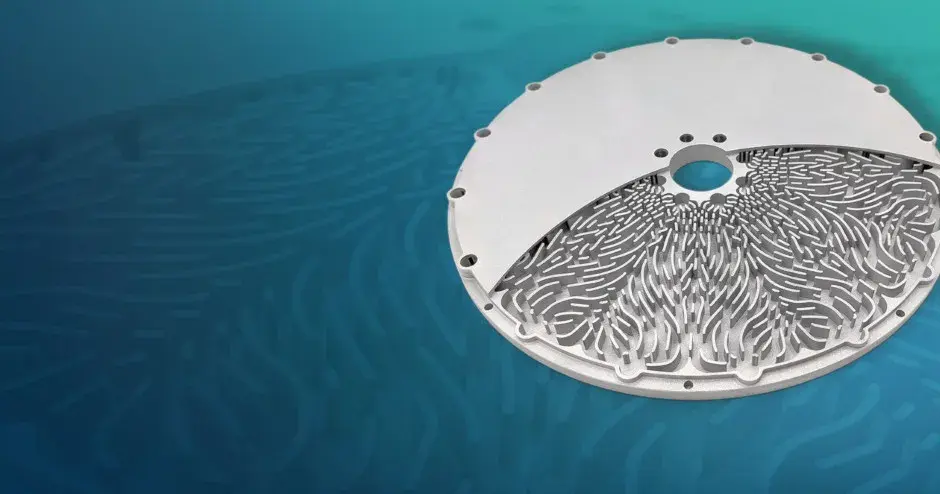

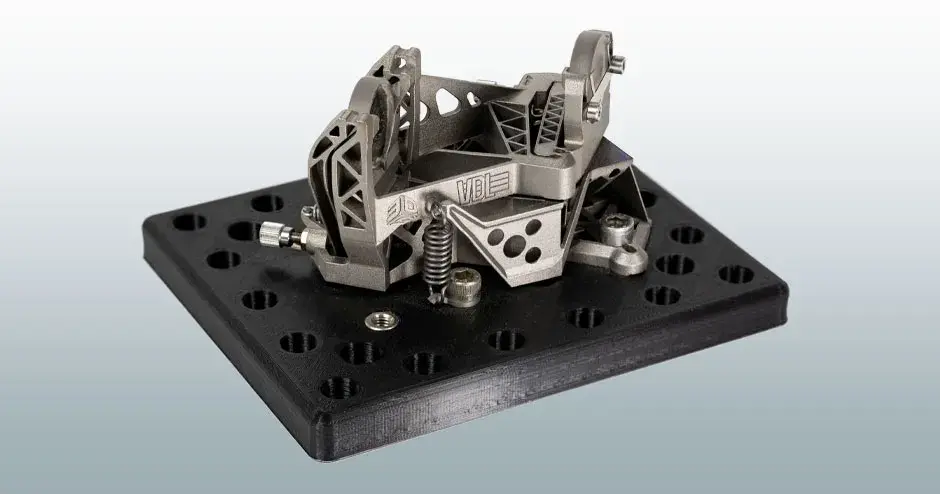

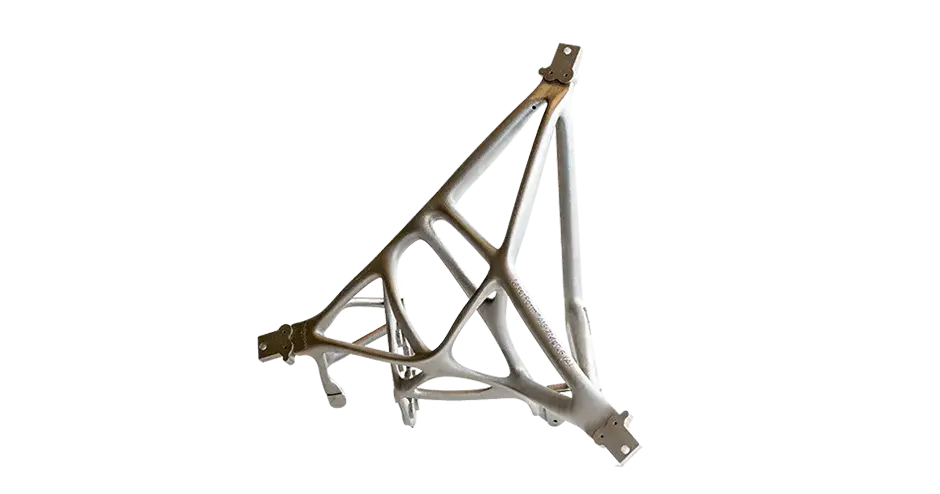

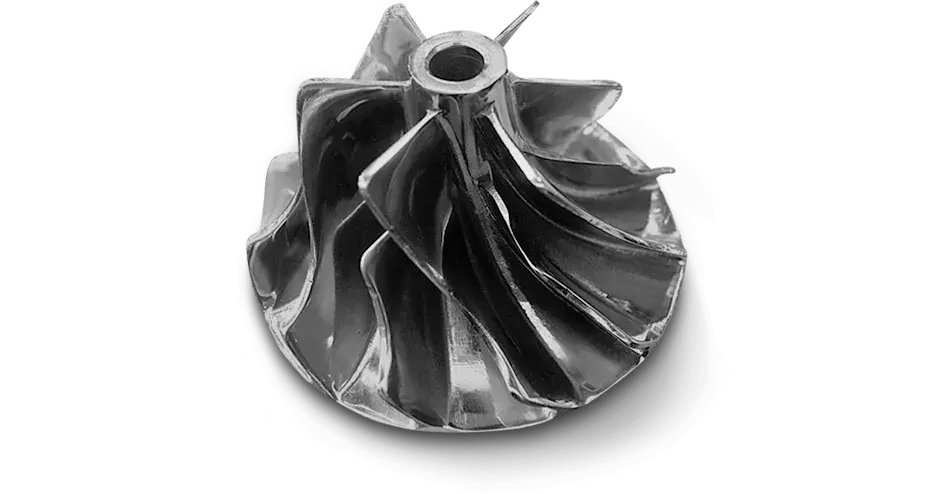

The Benefits of Metal Additive Manufacturing

Answer Challenges Related to Thermal Efficiency

Resources

More Semiconductor Applications

Learn More About Wafer Table Thermal Management 3D Printers and Materials

3DXpert

All-in-One Integrated Software for Industrial Additive Manufacturing

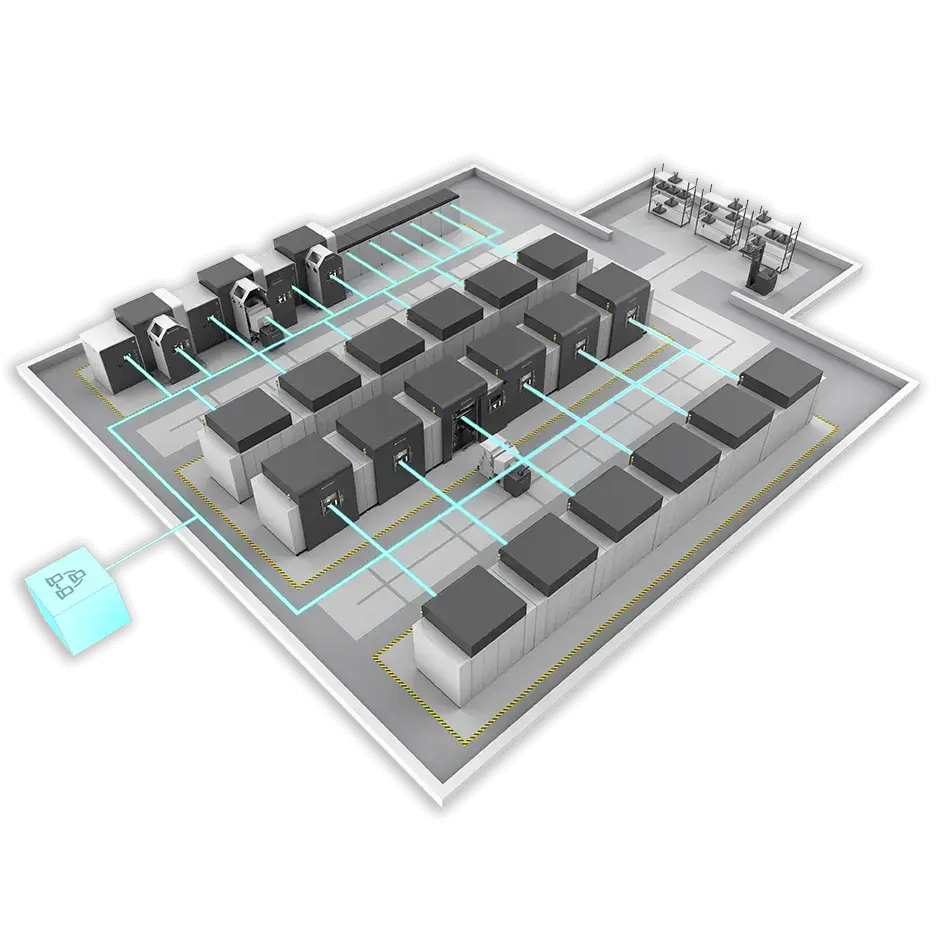

DMP Factory 500

Robust, high quality metal AM with integrated powder management

A6061-RAM2 (A)

Improved strength, ductility, and surface finish vs. AlSi10Mg

LaserForm AlSi10Mg (A)

Good mechanical properties and good thermal conductivity

LaserForm AlSi7Mg0.6 (A)

Light weight, good mechanical properties and improved thermal conductivity

LaserForm 316L (A)

Able to be sterilized and highly corrosion resistant.

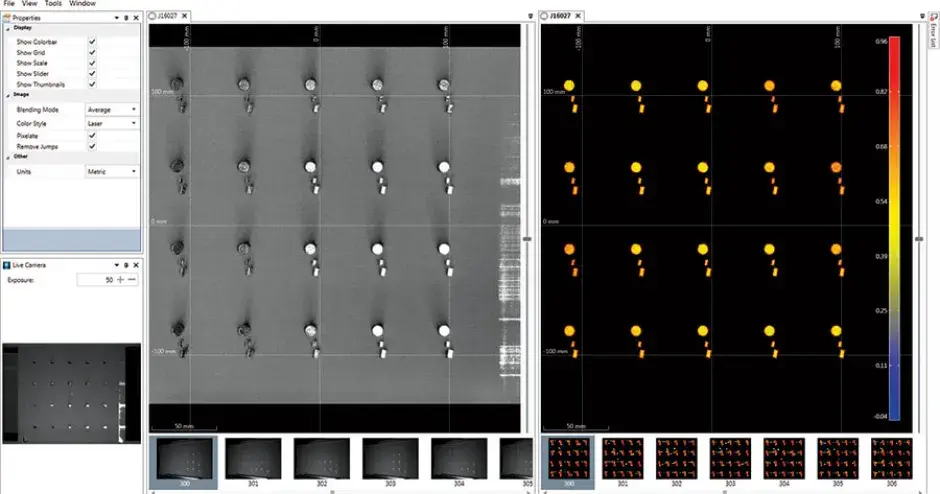

DMP Monitoring

Real-time process monitoring for informed decisions on product quality