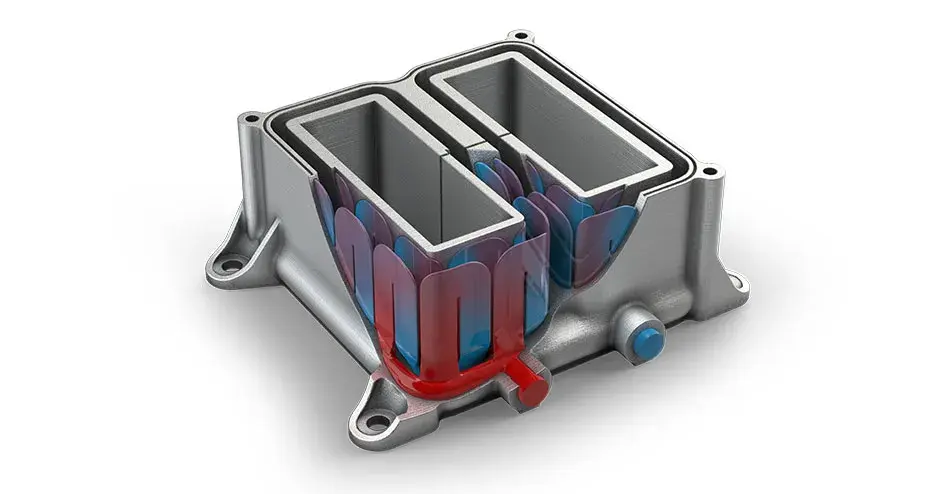

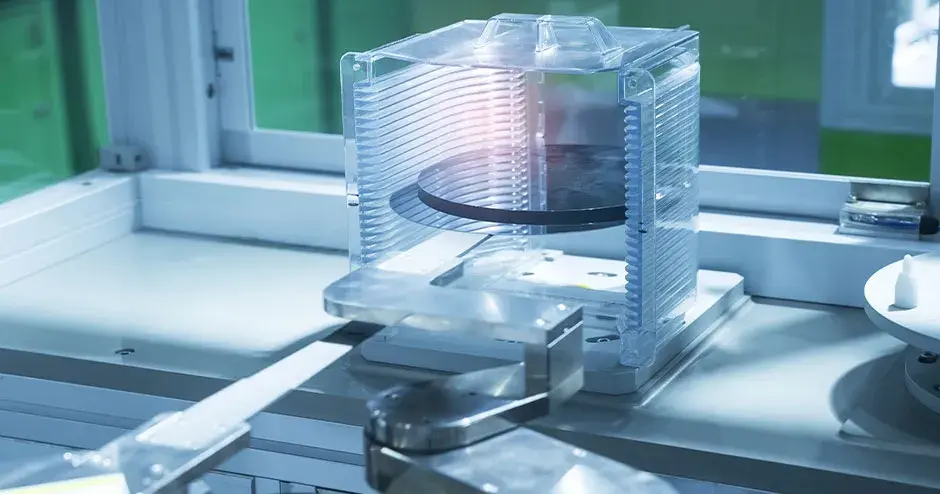

Deliver Longer Service Life of High-Speed Stages, Superior Cooling Efficiency and Performance with Monolithic, Leak-Proof, Metal 3D Printed Cooling Jackets.

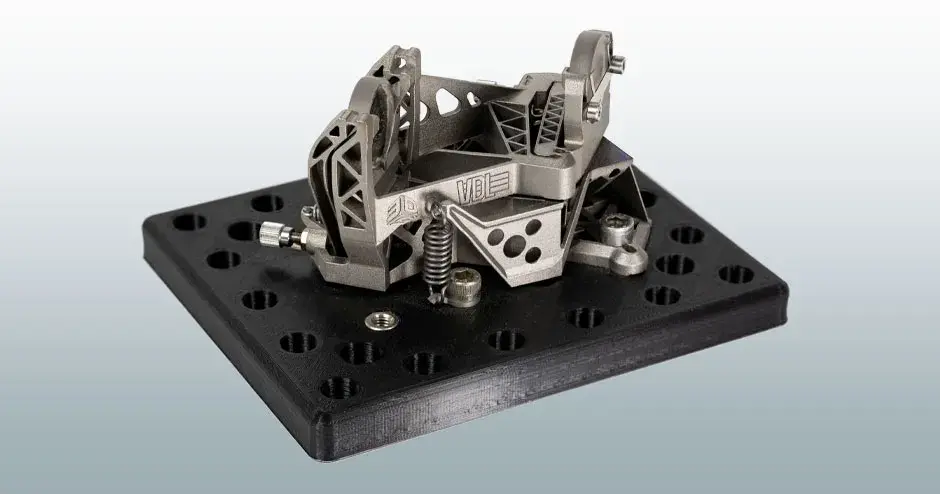

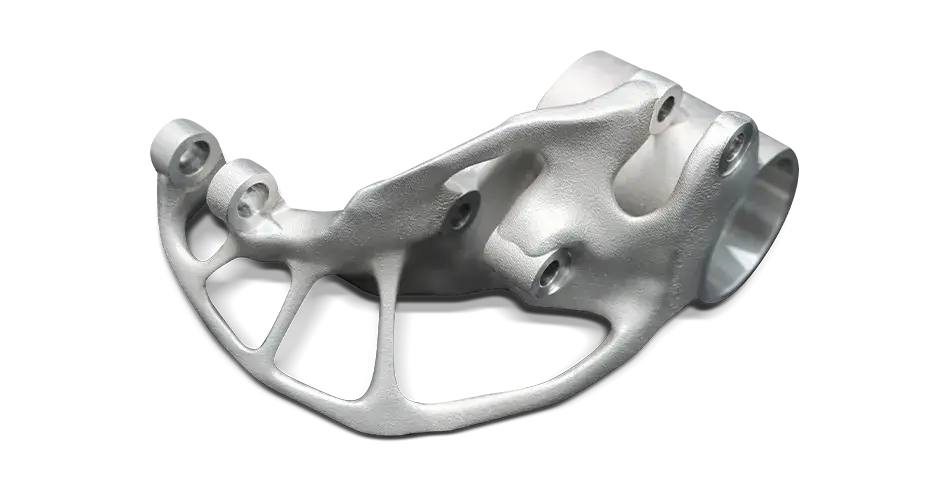

8:1

part consolidation

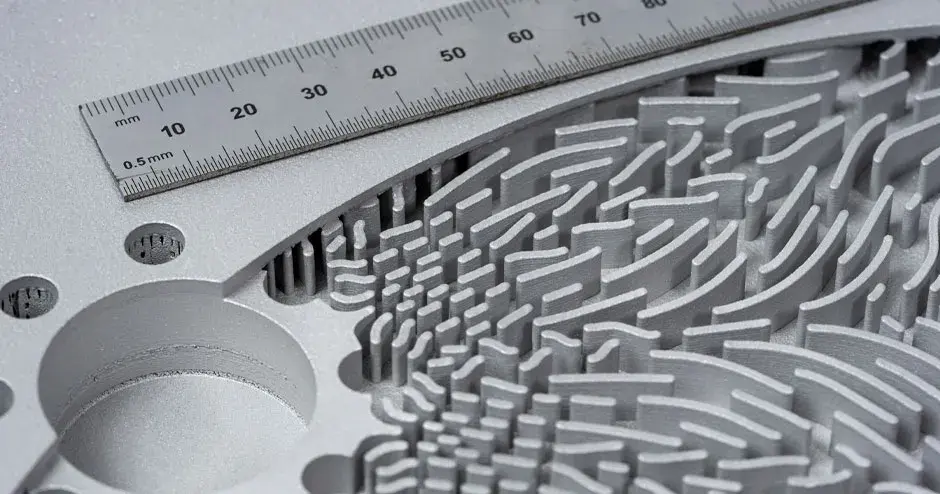

0.6 mm

wall thickness achieved

75%

component production time reduction

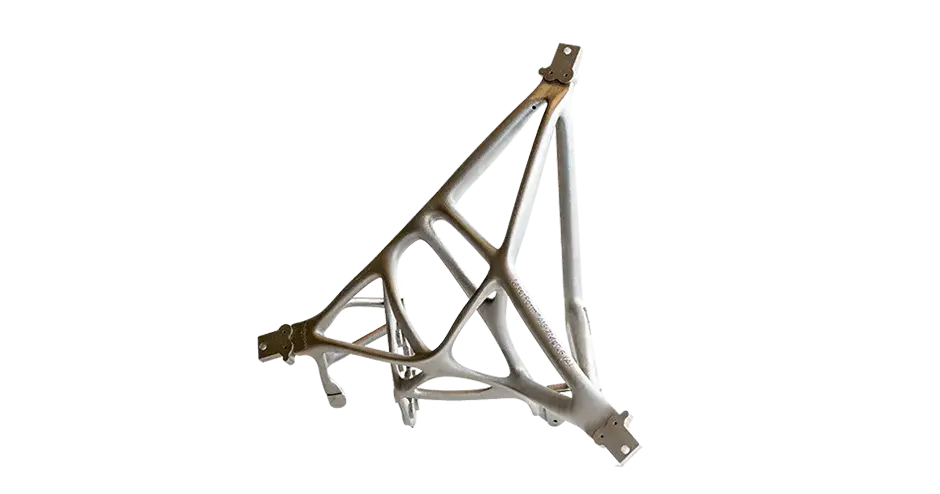

Increase Cooling Efficiency of Linear Stages While Reducing Part Count

The Benefits of Metal Additive Manufacturing

Your Path to More Efficient Linear Stages Coolers

Resources

More Semiconductor Applications

Learn More About Linear Stage Coolers Manufacturing Solutions

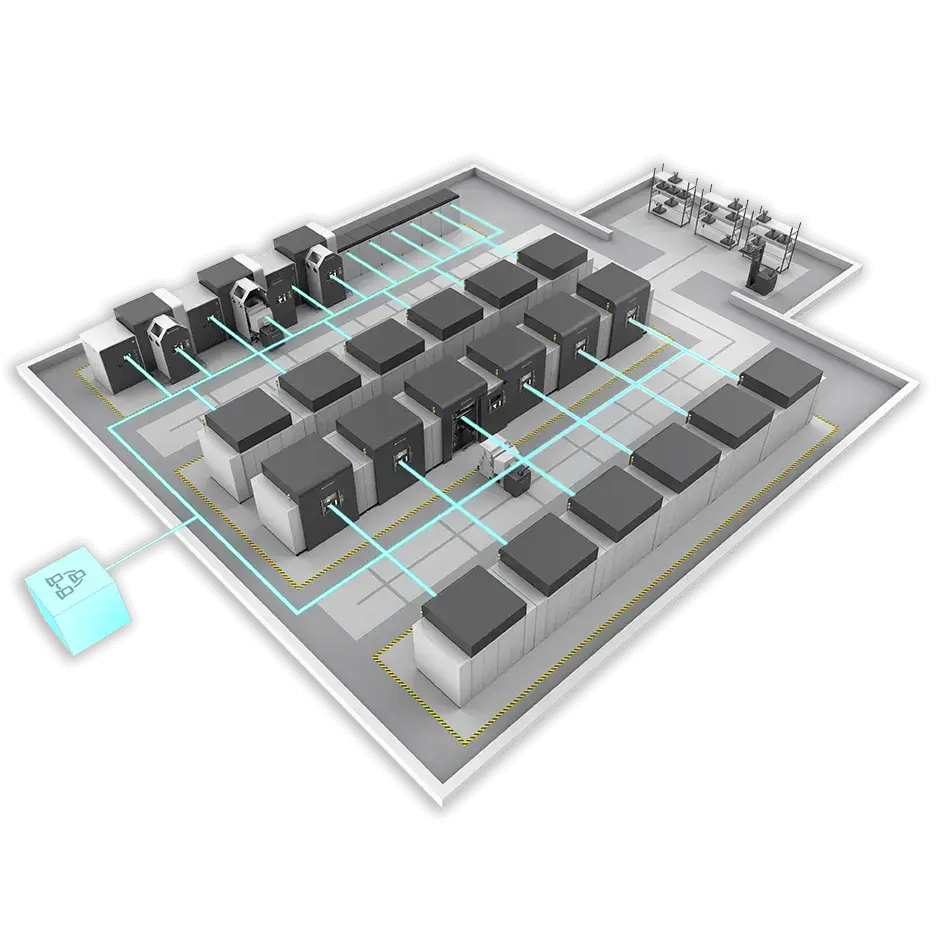

DMP Factory 500

Robust, high quality metal AM with integrated powder management

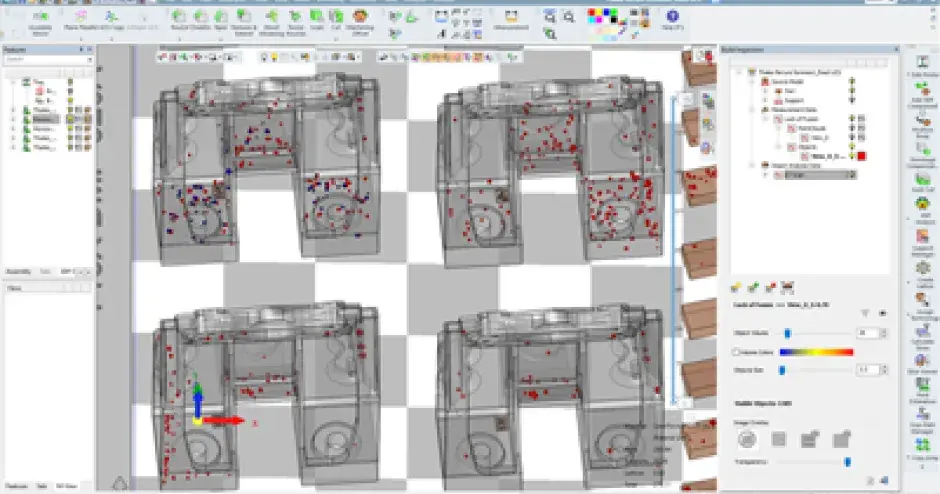

3DXpert

All-in-One Integrated Software for Industrial Additive Manufacturing

LaserForm 316L (A)

Able to be sterilized and highly corrosion resistant.

Certified Scalmalloy (A)

High strength aluminum with excellent corrosion resistance

LaserForm Ti Gr23 (A)

High strength, low weight, excellent biocompatibility - lower Oxygen than Gr5

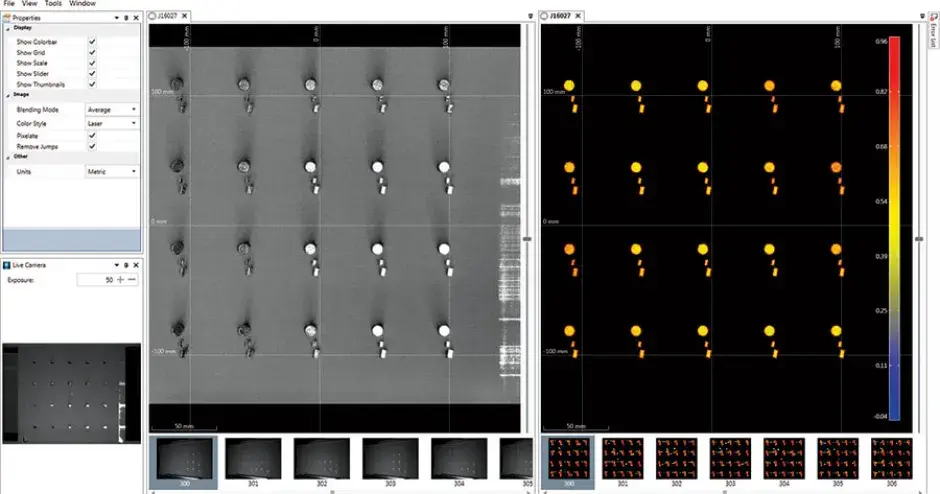

DMP Inspection

Minimize secondary inspection in Metal AM with validated automated analysis

DMP Monitoring

Real-time process monitoring for informed decisions on product quality

LaserForm AlSi10Mg (A)

Good mechanical properties and good thermal conductivity

LaserForm AlSi7Mg0.6 (A)

Light weight, good mechanical properties and improved thermal conductivity