Industrial Additive Solutions

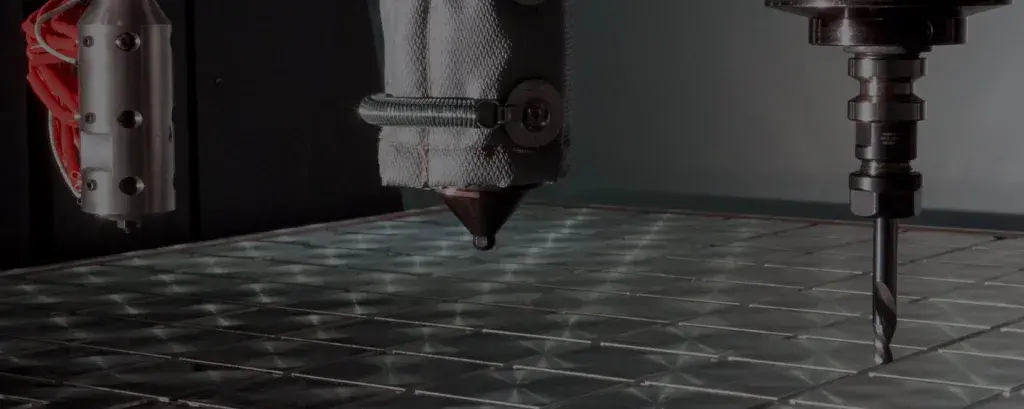

All EXT Titan printers are at home on the production floor, built with welded steel frames, industrial CNC controllers, servo-driven motion systems, actively heated chambers, and our proven high-throughput pellet extruders. Select systems may also be configured with filament extruders and milling spindle toolheads for true hybrid manufacturing.

-

EXT 800 Titan Pellet

Features a build volume of 800mm x 600mm x 800mm (31.5” x 23.6” x 31.5”) and fits through a set of standard double doors enabling installation in more locations.

-

EXT 1070 Titan Pellet

The EXT 1070 Titan Pellet (formerly known as Titan Atlas 2.5) has a build volume of 1070mm x 1070mm x 1118mm (42” x 42” x 44”)

-

EXT 1270 Titan Pellet

The EXT 1270 Titan Pellet (formerly known as Titan Atlas 3.6) features a massive build volume of 1270mm x 1270mm x 1829mm (50” x 50” x72”)

The EXT 1070 Titan Pellet (formerly known as Titan Atlas 2.5) has a build volume of 1070mm x 1070mm x 1219mm (42” x 42” x 48”)

The EXT 1270 Titan Pellet (formerly known as Titan Atlas 3.6) features a massive build volume of 1270mm x 1270mm x 1829mm (50” x 50” x72”)

Proven for Production

EXT Titan Pellet 3D printers are proven production additive manufacturing systems for applications including patterns, molds, tooling, jigs, fixtures, end-use parts, and full-scale prototypes. Designed for lights-out manufacturing, these systems can shorten cycle times, reduce costs, and increase up-time in your production processes.

All EXT Titan Pellet printers feature industrial CNC control systems with servo drives on all axes for increased speed and reliability. Built with a welded and precision machined steel frame and industrial heated enclosure, these 3D printers are ready to go to work on your production floor.

(Clockwise from lower left) Thermoforming mold printed with EXT 1270 Titan Pellet printer, untrimmed thermoformed panel, trimmed panel installed in train interior.

Why 3D Print with Pellets?

Why pellets? The first reason is cost. Thermoplastic pellets are the raw form of most plastics used in industrial forming processes like injection molding and thus cost up to 10x less than traditional 3D printing filament feedstock. Overall, thermoplastic pellets are considered one of the lowest cost 3D printing feedstocks.

Printing directly with pellets also enables faster print speeds. Higher throughput is inherent in the pellet extrusion process. Couple that with large nozzle sizes and 3D Systems' robust CNC motion control system, and print speeds can be 5X -10X faster with EXT Titan Pellet systems than traditional filament extrusion printing.

Finally, printing with pellets enables the use of a wide range of materials. There are 100’s of grades of thermoplastic pellets available for printing, including high-performance materials that are not available in filament form including high-percentage glass fiber and carbon fiber-filled plastics and low-shore TPE and TPU.

-

Learn More About Extrusion Materials and Technology