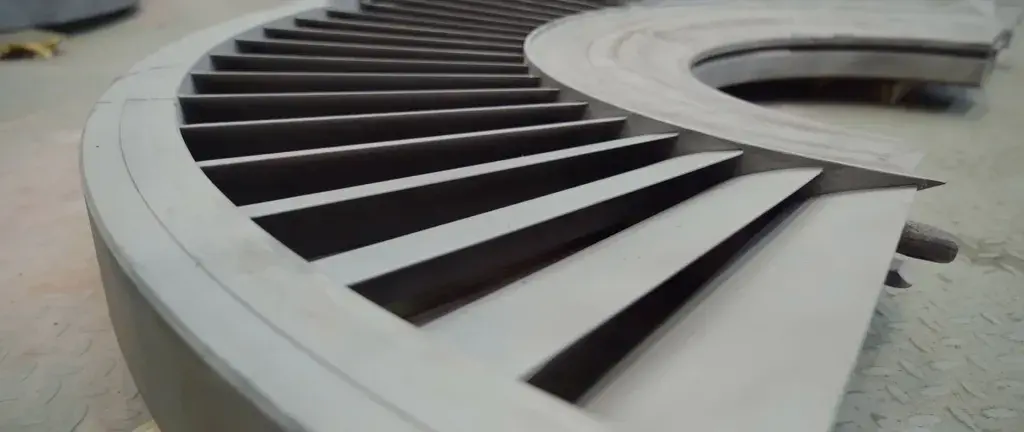

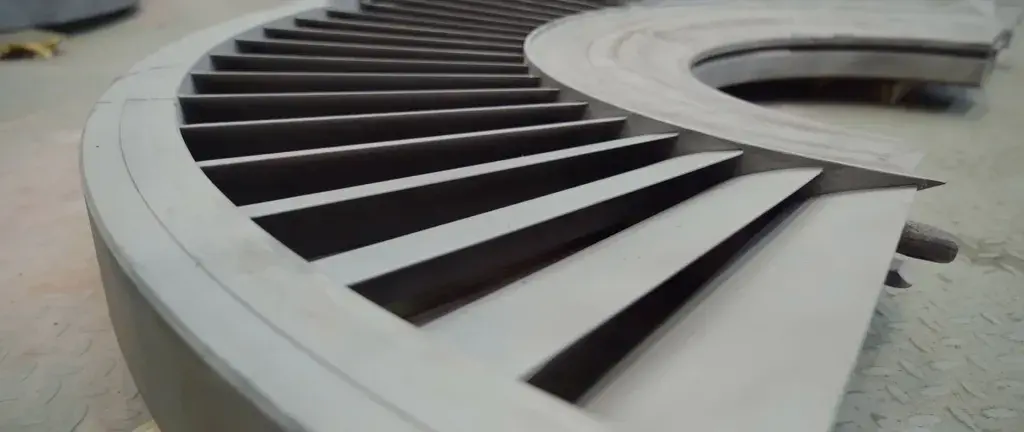

The parts used in turbomachinery must withstand intense thermal and structural loads. The highest requirements for part-level performance are inside hot zones of turbomachinery and among this group are compressor and turbine stator vanes, and integrated stators. With 3D Systems’ Additive Manufacturing (AM) solutions, it is possible to reduce points of failure generated by traditional complex manufacturing assemblies by consolidating several parts into one, which improves yield and reliability, and reduces manufacturing labor.

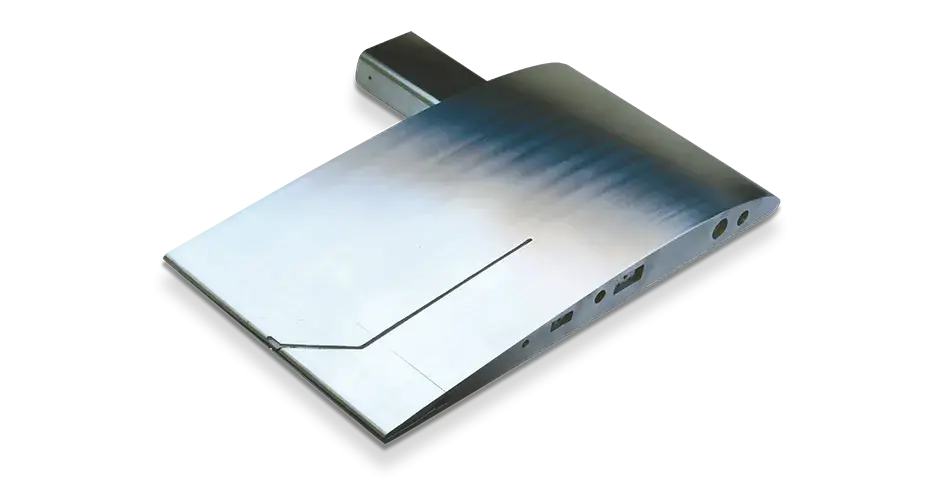

To achieve maximum efficiency and reliability, critical gas turbine components require complex internal cooling channels that are difficult to machine. Our solutions allow for the creation of optimal conformal cooling that improves thermal performance.

3D Systems Application Innovation Group (AIG) guides customers from design concept to product production and technology transfer into scalable manufacturing. We offer full DfAM (Design for Additive Manufacturing) consultation services, which include optimization of component geometries, cost and production optimization, additive manufacture planning, and experience with a wide array of finishing and post-processing technologies.

With our broad range of advanced additive manufacturing technologies, materials, and software solutions, we can deliver seamless 3D printed metal parts of 500 x 500 x 450 mm within tight tolerances and with outstanding material properties. For investment casting of any superalloy, you can print patterns up to 1500 mm long.

With our production facilities, we can be your agile manufacturing arm, helping you transition from prototype to production, while offering increased supply chain capacity and flexibility.

Digital processes and new additive manufacturing technologies are poised to deliver massive time and cost savings: Production workflows that traditionally take weeks can now be done in hours.

Download this eBook to learn how to reduce total part count, streamline production and elevate part performance with metal additive manufacturing.

Design, test and produce metal parts with 3D printing that are simply not possible with standard manufacturing. Create lightweight, high-strength structures and deliver new capabilities. Read the Metal Printing Design Guide to gain invaluable insight.

Robust, high quality metal AM with integrated powder management

Oxidation, corrosion and extremely high-temperature resistant

Highly accurate, humidity/moisture resistant, antimony-free casting patterns

All-in-One Integrated Software for Industrial Additive Manufacturing

Excellent corrosion resistance, high strength and heat resistance

All the benefits of SLA 3D printing in extra-large format

Minimize secondary inspection in Metal AM with validated automated analysis

Real-time process monitoring for informed decisions on product quality

High strength, low weight, excellent biocompatibility - lower Oxygen than Gr5