Benefits

High Throughput Dual Laser SLA System

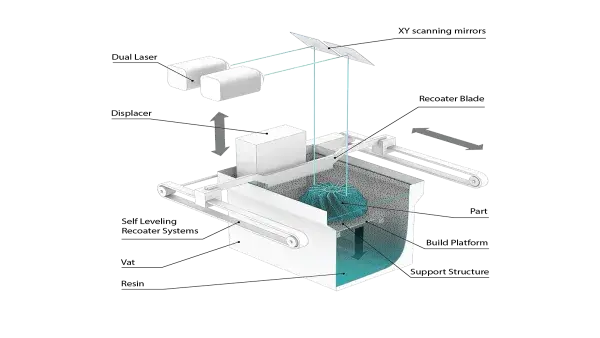

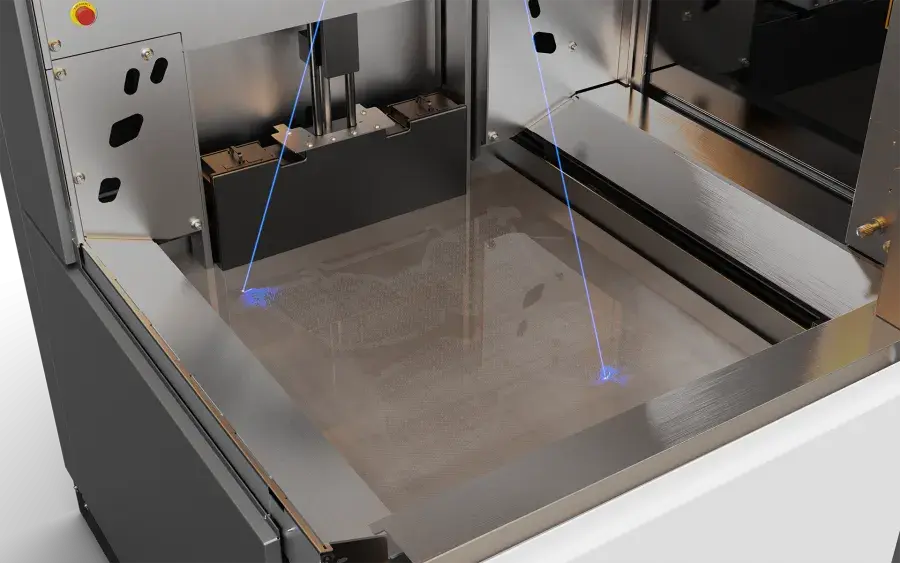

The SLA 825 Dual is a next-level, industrial, large frame SLA 3D printing solution engineered for high-speed, ultra-precise production of large format parts. Designed for high volume, time-intensive industries developing complex parts, the SLA 825 features synchronous high power dual lasers, the largest build volume in its class, ultra-high speed scanning technology, and a full-solution workflow.

Key Features

Large Build Area

High Resolution

High Speed

High Yield

High Accuracy

Reliable 3D Printed Results Across Advanced Applications

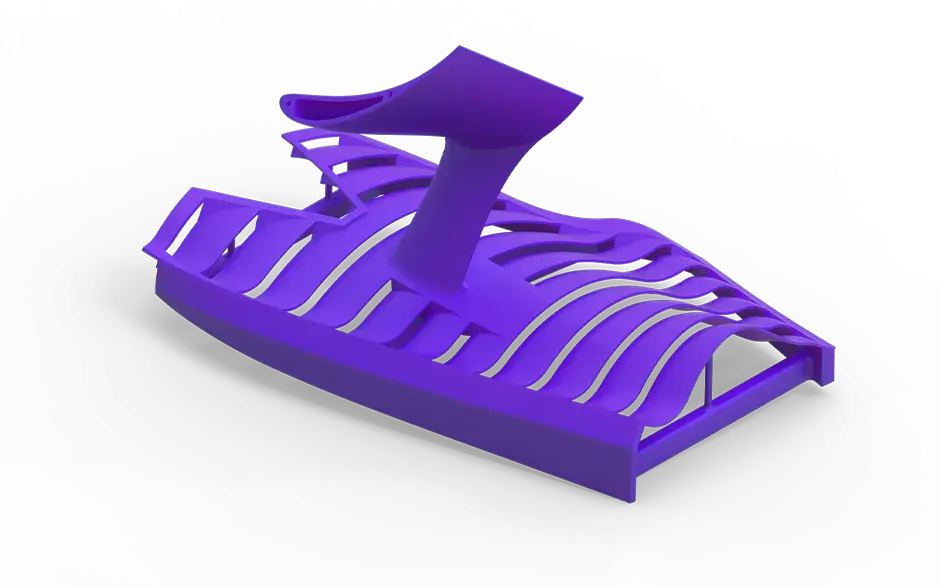

The system produces 3D printed parts with outstanding surface finish, precise dimensional accuracy, and consistent reliability across production-grade applications.

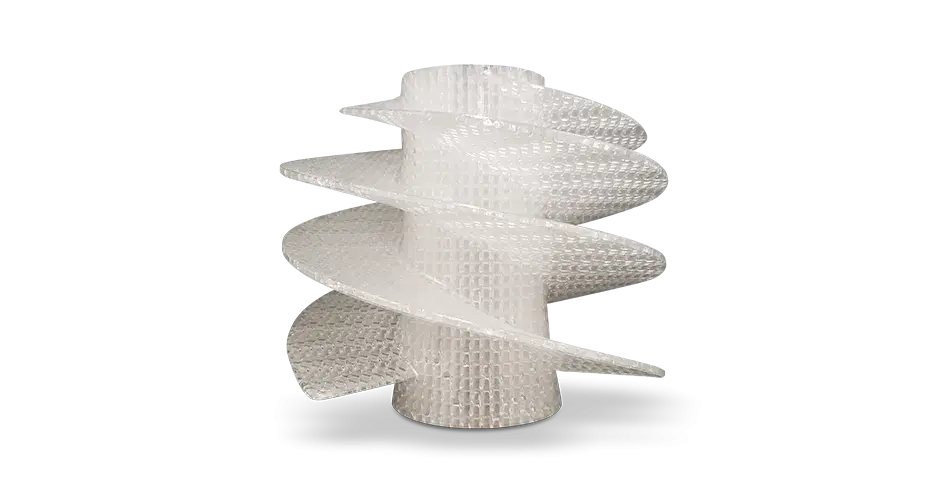

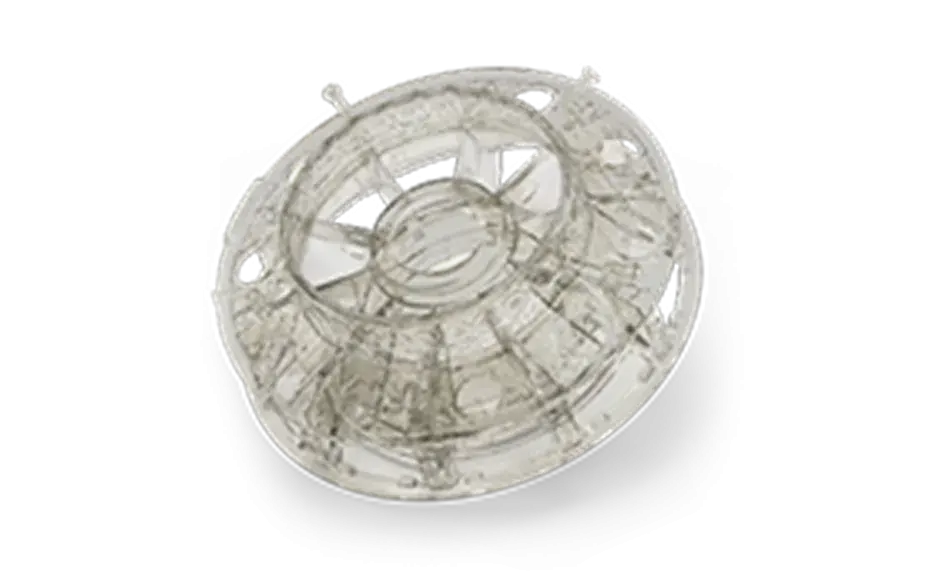

Foundries

High volumetric throughput for investment casting patterns with competitive cost-per-part.

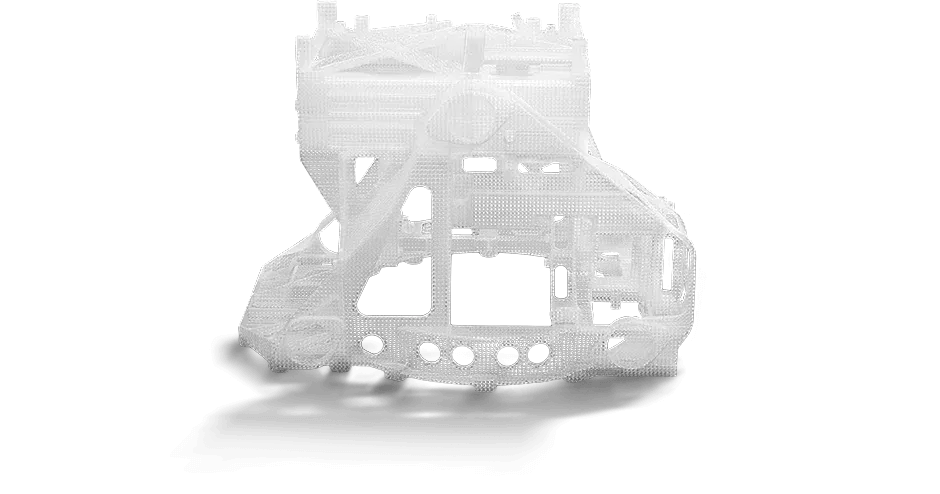

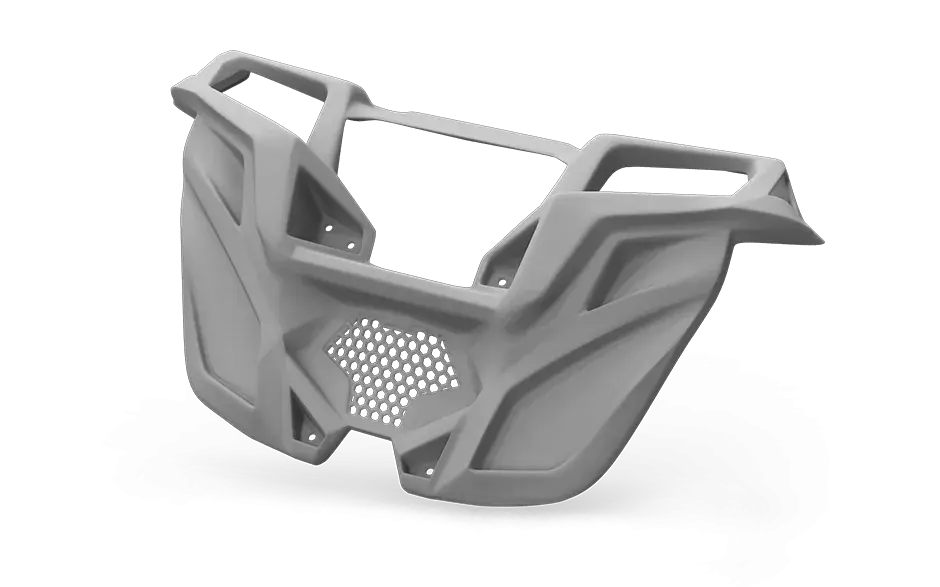

Auto & Motorsports

High-speed builds with accuracy and minimal post-processing. Automotive industries Motorsports industries

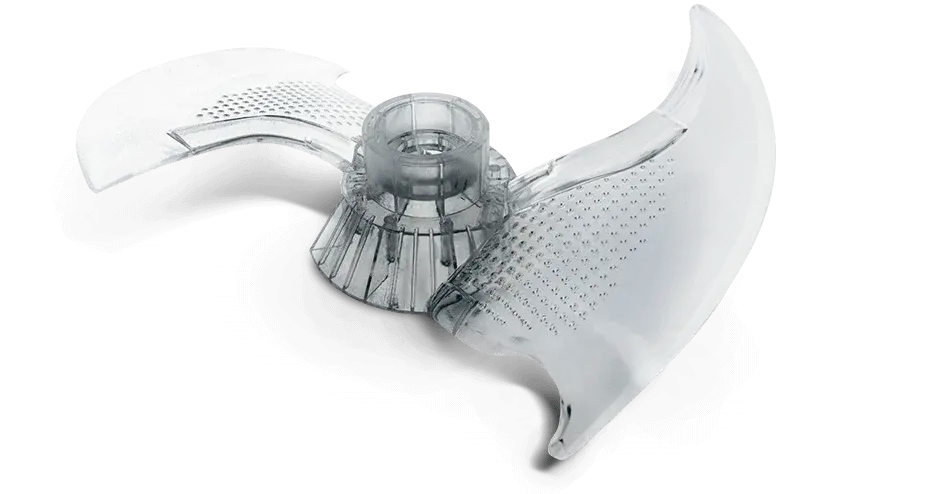

Aerospace & Defense

Large investment casting patterns, prototypes, and fixture tooling.

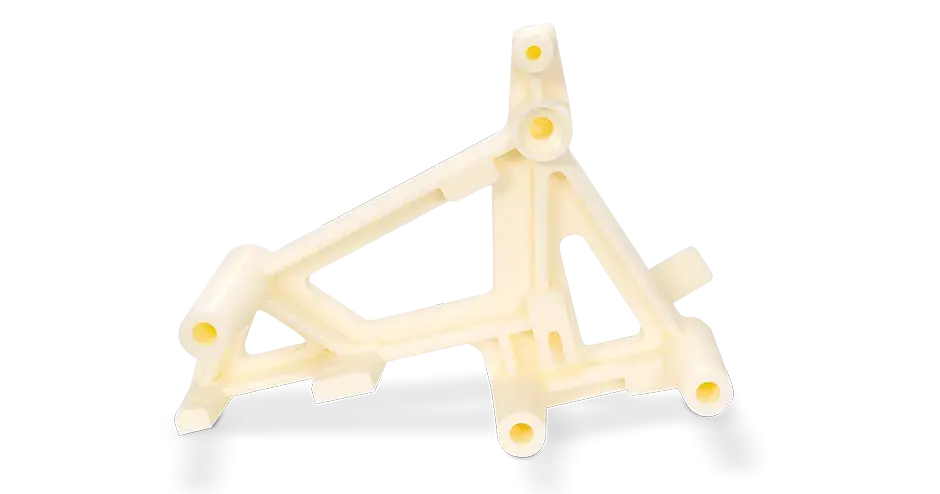

Service Bureaus

High throughput, reliability and multi-geometry capacity.

Introducing the SLA 825 Dual: High-throughput industrial 3D printing

Design Highlights

Removable Vats

Clean Interior

Material Loading

Recoater Design

Material Leveling

Materials Compatible with this Printer:

Accura Composite PIV

High production speeds with exceptional stiffness/rigidity

Accura Xtreme (SLA)

Ultra-tough grey plastic, replaces CNC-machined polypropelene and ABS

Accura Xtreme Black

Functional prototyping plastic material, providing accurate, tough black parts with excellent surface finish and detail

Accura Xtreme White 200 (SLA)

Ultra-tough white plastic, replaces CNC-machined polypropelene and ABS

Accura CastPro (SLA)

Highly accurate with excellent humidity/moisture resistance

Accura SbF

Manufacture high yield, high quality and stable investment casting patterns with ultra-low viscosity, antimony-free stereolithography (SLA) resin

Accura 25 (SLA)

Flexible, accurate, aesthetics of molded polypropylene (PP)

Accura 55 (SLA)

Rigid, accurate plastic, aesthetics of molded ABS.

Accura 60 (SLA)

Hard, clear plastic, aesthetics of molded polycarbonate (PC).

Accura AMX Durable Natural

Production-grade resin featuring long-term environmental stability

Accura AMX Rigid Black

Production-grade resin featuring long-term environmental stability

Accura AMX Tough FR V0 Black

Tough black, UL94 V0 rated flame-retardant production plastic

Accura Bluestone (SLA)

Composite material for stable, high stiffness parts

Accura ClearVue (SLA)

High clarity plastic, multitude of applications

Accura PEAK (SLA)

Stiff plastic material for heat-resistant components

Accura HPC

High production speeds with exceptional stiffness/rigidity

Accura AMX High Temp 300C

Ultra-high temperature resistant rigid plastic engineered to withstand the harshest thermal environments

Upcoming SLA 750 Events

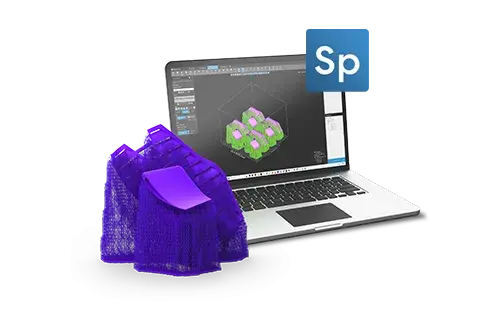

The 3D Systems Ecosystem

3D systems had developed a tightly integrated hardware–software–materials ecosystem designed to make professional 3D printing accessible, reliable, and scalable.

Material

Integrated into 3D Systems’ overall AM solution. Fine tuned to achieve high-end application mechanical performance.

Software

Streamline time to print and time to finished parts from a single integrated 3D Systems’ interface.

3D Printer

Deliver large production parts, prototypes, investment casting patterns, and fixture tooling faster than ever before.

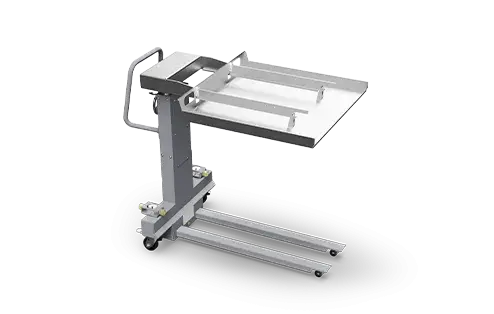

Offload Cart

Transport and remove your build platform and parts to and from the 3D printer.

Cure & Dry

3D Systems’ PostCure1050 delivers uniform, high-intensity UV curing to ensure part mechanical performance.

Advanced User Experience Architecture

New Design

Touch UI

Print Tracking

Easy to Use

Remote Monitoring

SLA 825 Dual