Benefits of the SLS 300

Compact Size with a Maximum Build Capacity

The SLS 300 has a small footprint while offering big opportunities. The printer takes only 0.45 sq. meters or 4.8 sq. ft. floor space with no infrastructure needed. It uses standard power, is low in office noise levels and requires no chiller or fume extractor

About this printer

Applications

- Prototypes

- Functional parts

- Small complex parts

- Parts for the automotive industry

- Medical supplies

- Pipelines and fittings for water pipes

- Industrial components

Benefits

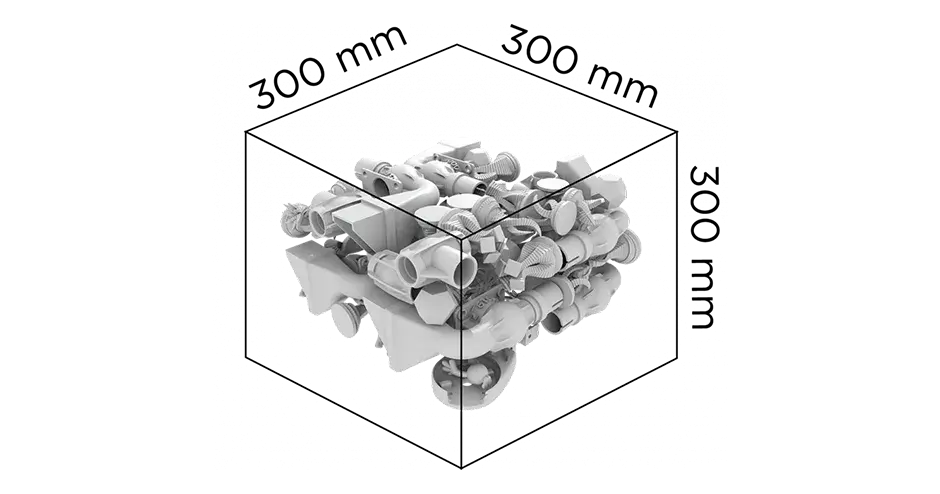

- Large build volume (27 liters)

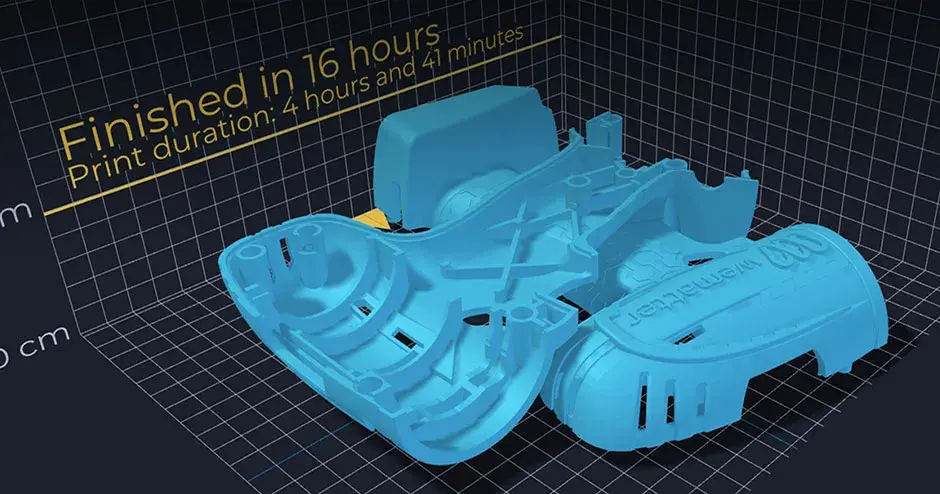

- High print speed (12 mm per hour)

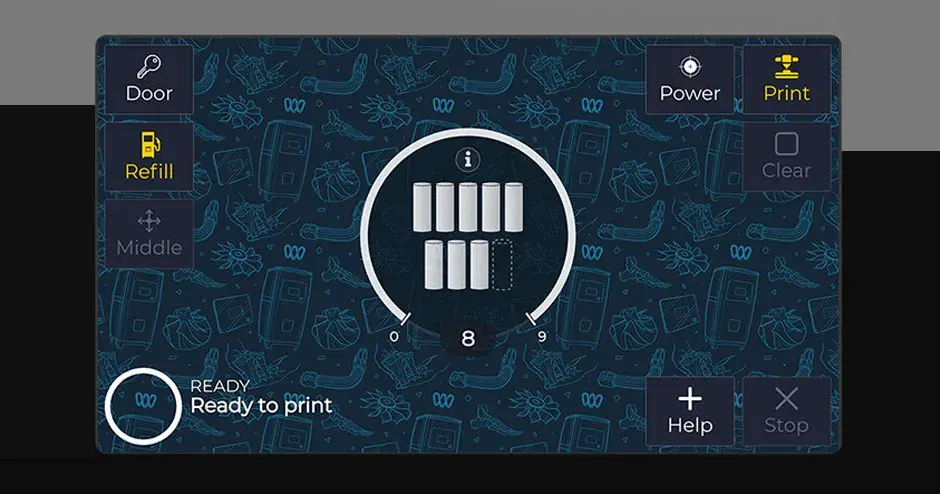

- Remote monitoring of build

- Remote 13-inch control panel

- Optical material identification

Tech Specs

- Build Volume: up to (W x D x H): 12 x 12 x 12 in (300 x 300 x 300 mm)

- Precision: 0.1 mm

- Footprint: less than 1 square meter

- Machine Dimensions: 170 x 75 x 60 cm

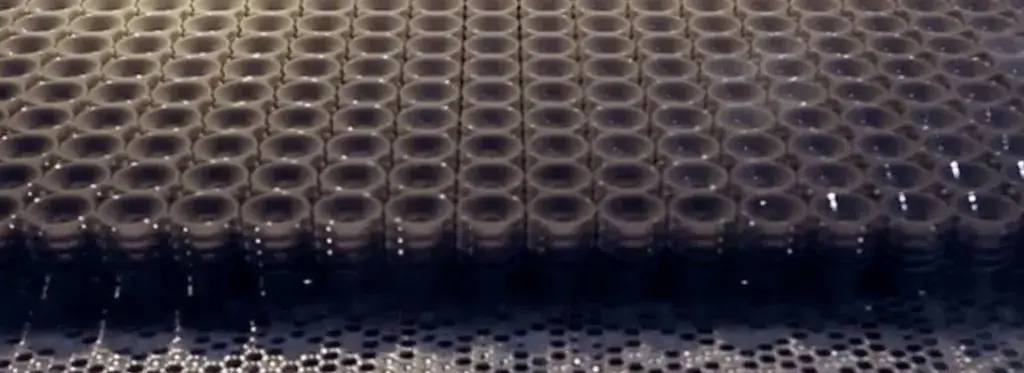

- Print Technology: Powder Bed Fusion > Selective Laser Sintering

- Speed: 12 mm per hour

- Weight: 310 kg

- Internet connection: Ethernet 1 Gigabit

- Power: (EU) 230V AC 10A 50 Hz / (US) 115V AC 15A 60 Hz

A Customizable 3D Printing Solution for the Office

The SLS 300 solution is available in a package with optional accessories to meet your business needs.

Interested in purchasing this printer?

You Might Also Be Interested In

SLS 380

Industrial-scale, process controlled additive manufacturing solution for selective laser sintering