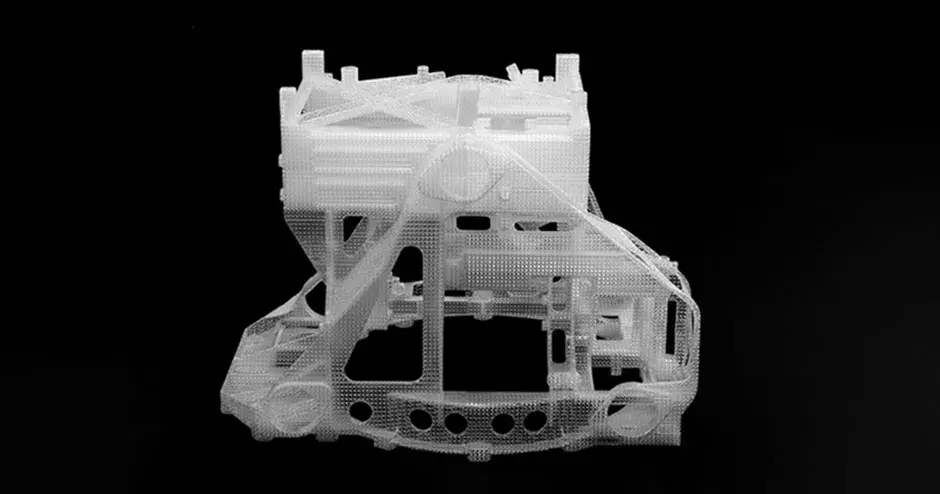

During the testing and iteration stages of finished metal part production, the ability to quickly cast metal parts is critical. Manufacturing master patterns for investment casting with traditional means was previously a time-consuming process, however, our additive manufacturing methods offer motorsports engineering and manufacturing teams innovative solutions to rapidly manufacture precise master patterns which are then used to cast high-performance metal parts.

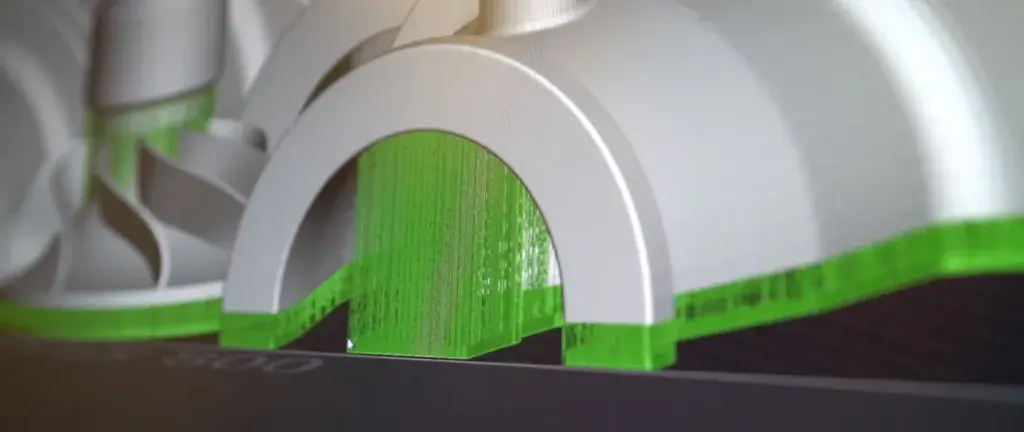

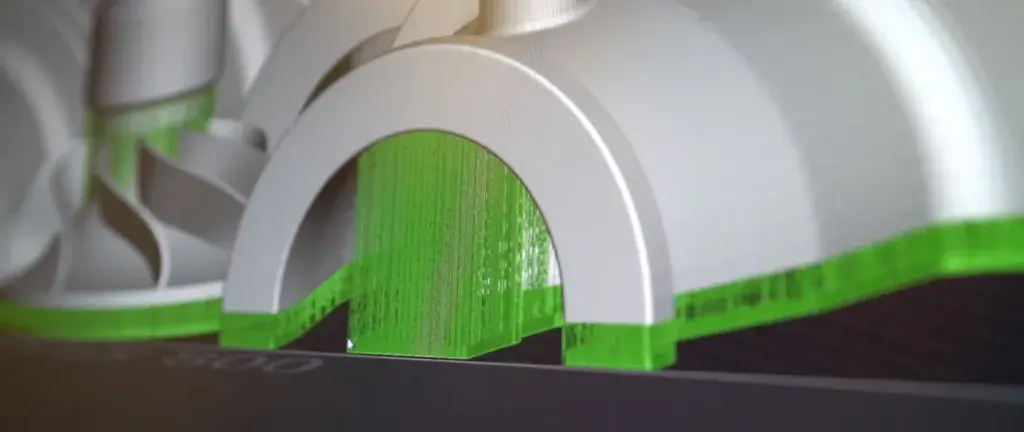

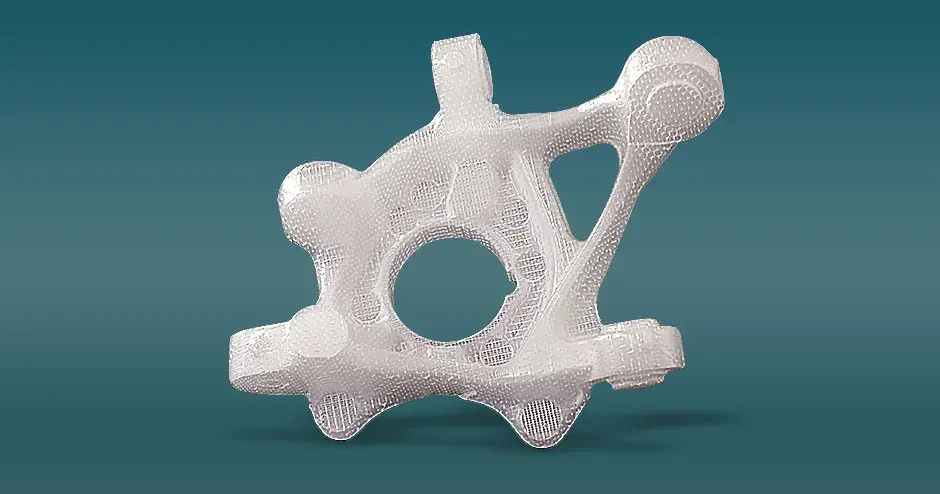

The QuickCast stereolithography (SLA) process that 3D Systems developed for investment casting delivers lightweight, accurate master patterns at unprecedented speed and quality. The QuickCast process is ideal for the motorsports market, which often requires low volumes of highly complex parts.

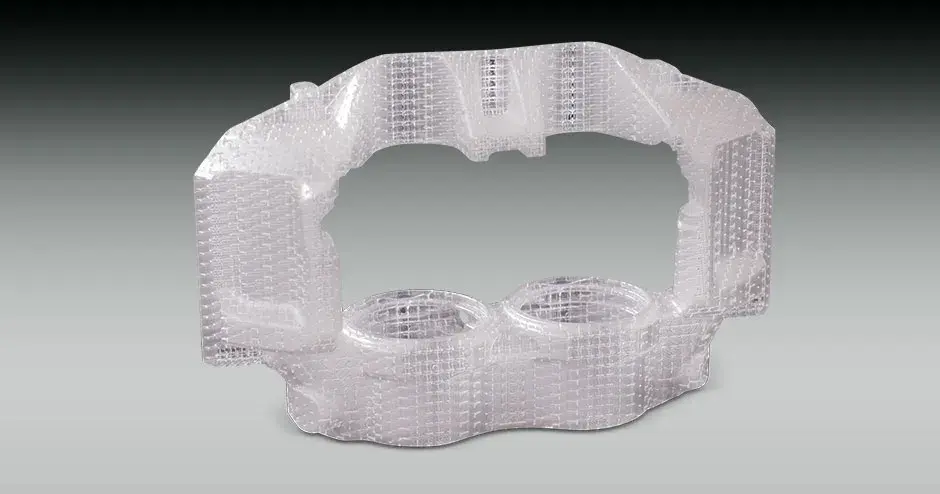

Highly accurate, humidity/moisture resistant, antimony-free casting patterns

Highly accurate with excellent humidity/moisture resistance