The powertrain and engine area is a constrained space in the core of a race car, key to delivering high performance. Designing and packaging parts for this area is a challenge as parts mounted in this environment must withstand harsh conditions such as heat cycling, vibrations, and corrosive fluids.

Our additive manufacturing solutions enable engineers to design components that fit into these constraints and withstand such conditions. Through advanced material science and incredible accuracy, 3D Systems maximizes automotive performance and drives success on the track.

Strong, tough polyamide (nylon) material for production parts

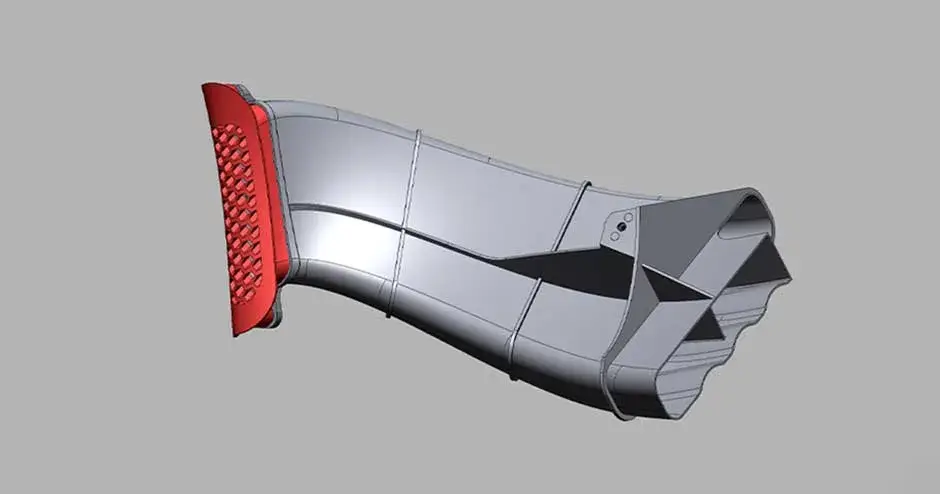

A fiber-reinforced engineering plastic, high temperature resistance

A fiber-reinforced engineering plastic, high temperature resistance

Durable polyamide (nylon) material for production parts