We have discontinued production of the FabPro 1000 (including the FabPro 1000 for Dental)

3D Systems intends to provide materials, parts and service support for the FabPro 1000 for three years through July 1, 2024. Over this period, our suppliers may discontinue certain components and parts. In that case, we will make reasonable efforts to locate alternate suppliers, provide remanufactured parts or, when necessary, develop upgrade kits to adapt to available alternatives.

If you require assistance, please contact support for your FabPro 1000 or visit our InfoCenter for documentation related to the FabPro 1000 3D printer.

FabPro 1000 materials can be ordered using the list below:

FabPro Tough BLK

Durable production plastic

FabPro Proto GRY

Fast, general purpose plastic

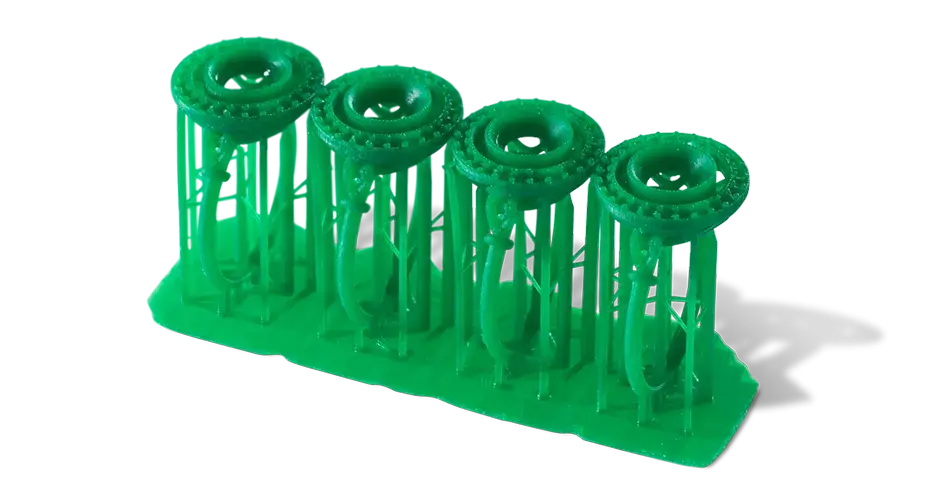

FabPro JewelCast GRN

Green material for jewelry casting patterns

NextDent SG (Surgical Guide)

3D Print resin for the manufacturing of dental surgical guides

NextDent Model 2.0

3D Print Resins for the manufacturing of prosthodontic and orthodontic models

NextDent Ortho Rigid

3D Print resin for the manufacturing of dental splints

You Might Also Be Interested In:

Figure 4 Standalone

Ultra-fast and affordable for same day prototyping and low-volume production

ProJet MJP 2500 Plus

MultiJet printing quality, speed and ease of use made accessible

NextDent 5100

Redefining digital dentistry