Benefits

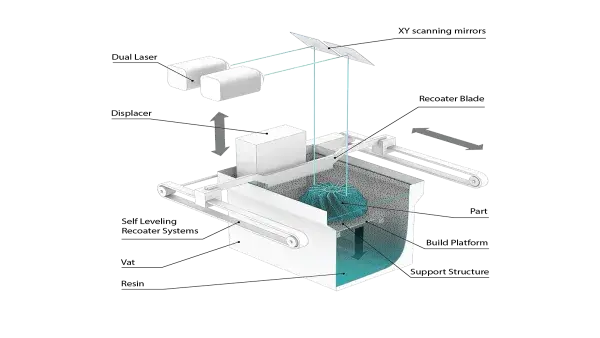

High Throughput Dual Laser SLA System

Unlock high-throughput, high-accuracy production of models for clear aligner thermoforming with the SLA 825 Dual stereolithography (SLA) solution designed for high volume, time-intensive industries developing complex parts.

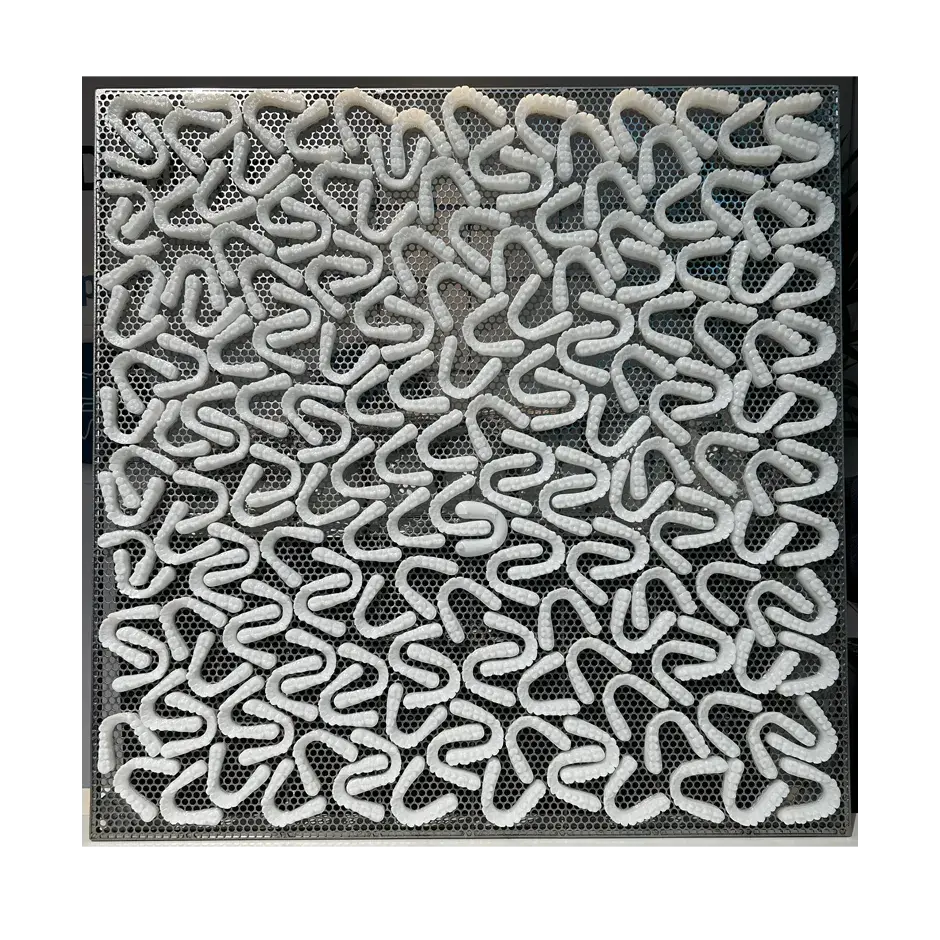

In dental manufacturing, accuracy is everything. The SLA 825 Dual platform delivers industry-leading dimensional accuracy and repeatability, enabling clear aligner thermoforming tools that meet tight dimensional tolerances for optimal fit and treatment outcomes.

High-Precision, Reliable Results

- Uniform accuracy across the entire build platform

- Largest build volume in its class

- Lower total production costs by requiring fewer machines and less labor

- Repeatable output across hundreds of models per batch

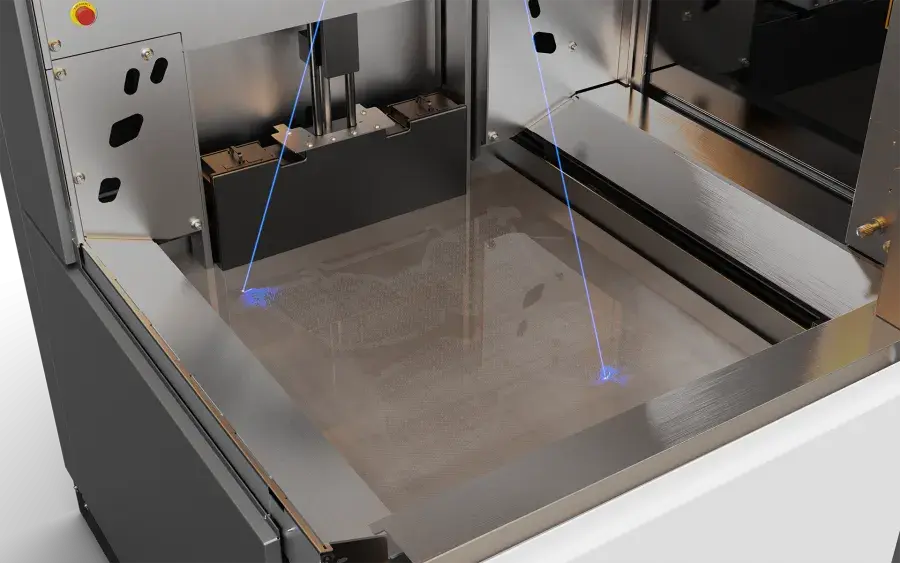

Scalable Throughput with Dual-Laser SLA Technology

SLA 825 Dual combines the largest build volume in its class, ultra-high speed scanning technology, and a full-solution workflow to meet the needs of dental labs.

- Print up to 2x faster than single-laser SLA systems

- Triple the throughput of previous generation or smaller platform SLA printers

- Designed and optimized for continuous, 24/7 production

24/7 Lights-Out Operation and Fleet Automation Readiness

The SLA 825 Dual comes with downstream automation readiness and robot compatibility for 24/7 lights out operation including fully automatic printer turnover with job offloading, post-print washing, and on-boarding. This 3D printer comes with a robot accessible chamber handle, fixed start and stop buttons, robot cycle start controls similar to CNC machines, automatic bottle or bulk material feed and connectivity ports.

Production and Quality Features

Large Build Area

High Resolution

High Speed

High Yield

High Accuracy

Upcoming SLA 825 Dual for Dental Events

The 3D Systems Ecosystem

Accura Ortho White

This material offers the optimal combination of accuracy, surface quality, and clean demolding.

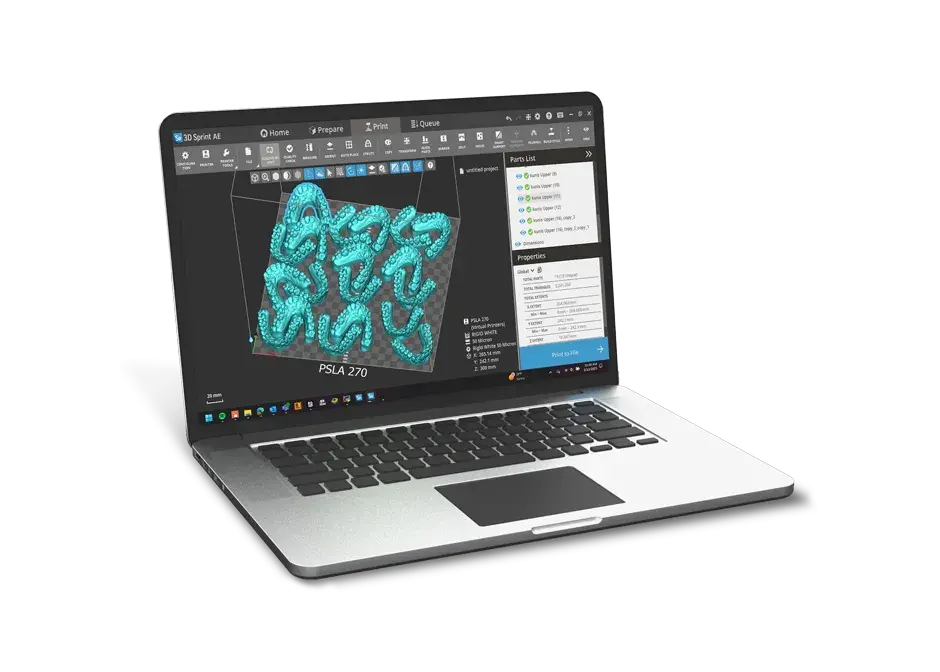

3D Sprint Software

Streamline time to print and time to finished parts from a single integrated 3D Systems’ interface.

3D Printer

Deliver large production parts, prototypes, investment casting patterns, and fixture tooling faster than ever before.

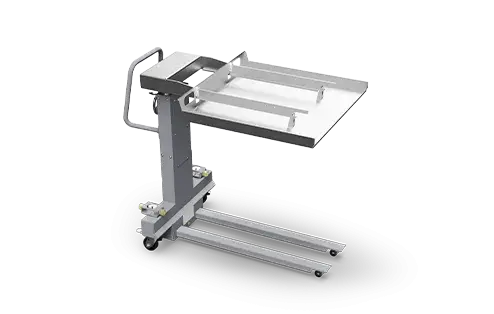

Offload Cart

Transport and remove your build platform and parts to and from the 3D printer.

Cure & Dry

3D Systems’ PostCure1050 delivers uniform, high-intensity UV curing to ensure part mechanical performance.