From mass production to chairside agility – discover the right solution for your workflow.

-

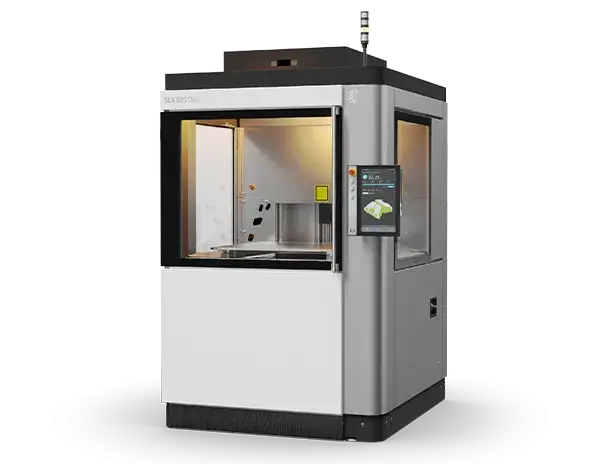

SLA 825 Dual

- Parts per build: ~270 models

- Print time: ~4 hrs 11 min

-

PSLA 270

- Parts per build: ~30 models

- Print time: ~30 min

-

NextDent 5100

- Parts per build: ~24 models

- Print time: ~2 hrs

SLA 825 Dual for Dental

Bigger Builds. Faster Throughput. Reliable Results.

The SLA 825 Dual is a next-level, industrial, large frame SLA 3D printing solution designed for high volume, time-intensive industries developing complex parts, the SLA 825 Dual combines the largest build volume in its class, ultra-high speed scanning technology, and a full-solution workflow.

Compatible with Accura Ortho White.

PSLA 270

Precision Performance. Scaled to Fit.

The PSLA 270 delivers the same industrial-grade accuracy and material efficiency in a compact, modular system—perfect for aligner producers looking to scale smart and fast.

Compatible with NextDent Model Ortho.

NextDent 5100

Fast. Flexible. Formulated for Dentistry.

The NextDent 5100 is purpose-built for rapid, chairside or lab-based dental production. With industry leading print speeds, affordable workflows, and certified dental materials, it's the smart solution for agile aligner manufacturing and more.

Compatible with NextDent Model Ortho.

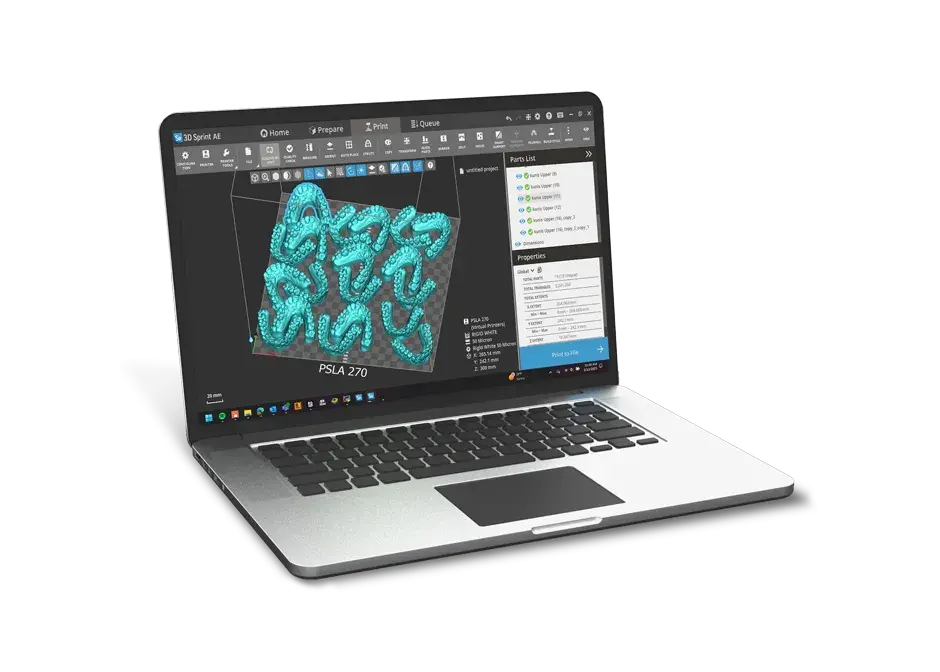

Our Solutions starts with our Software

From scan to print—streamlined, simplified, scalable.

3D Systems’ proprietary 3D Sprint®

software streamlines preparation, optimization, and production management, providing efficiency and precision while reducing reliance on high-cost external software.

Advanced Print Preparation Software

- One platform for file repair, nesting, support generation, and slicing

- Optimized for dental workflows, reducing print prep from hours to minutes

- Seamlessly integrates with SLA 750, PSLA 270, and NextDent 5100

- Improves throughput and part consistency at scale

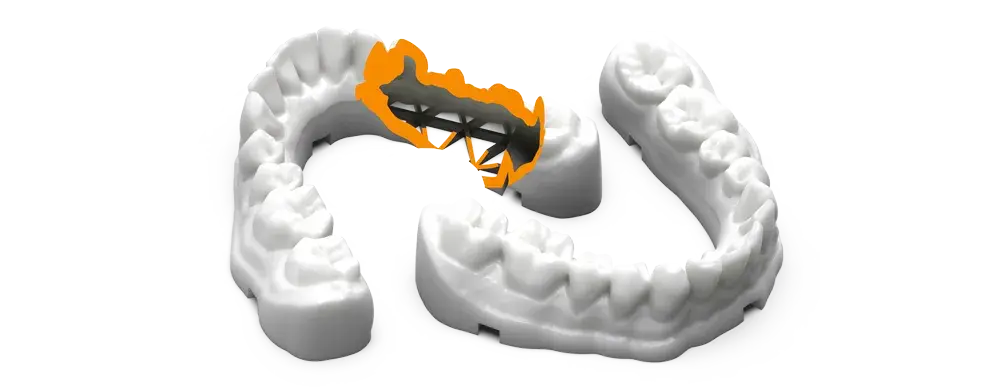

Single-click optimization of orthodontic dental models.

Developed specifically for orthodontic thermoforming workflows.

-

- Automatically generates shell geometries tailored to material performance

- Eliminates the need for manual optimization or in-house custom scripting

- Reduces variability and improves fit — every print, every time

Automatically generates shell geometries tailored to material performance

Eliminates the need for manual optimization or in-house custom scripting

Reduces variability and improves fit — every print, every time

-

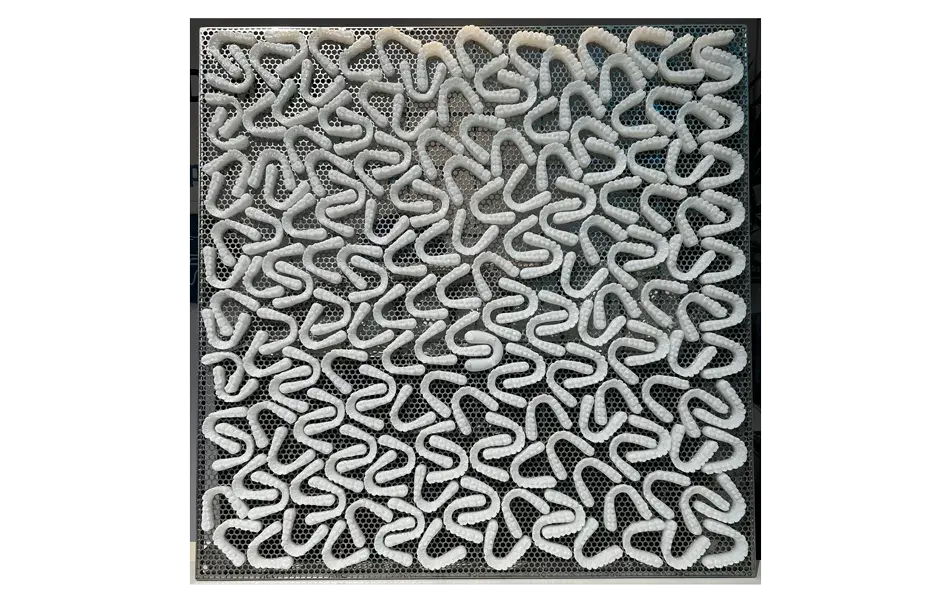

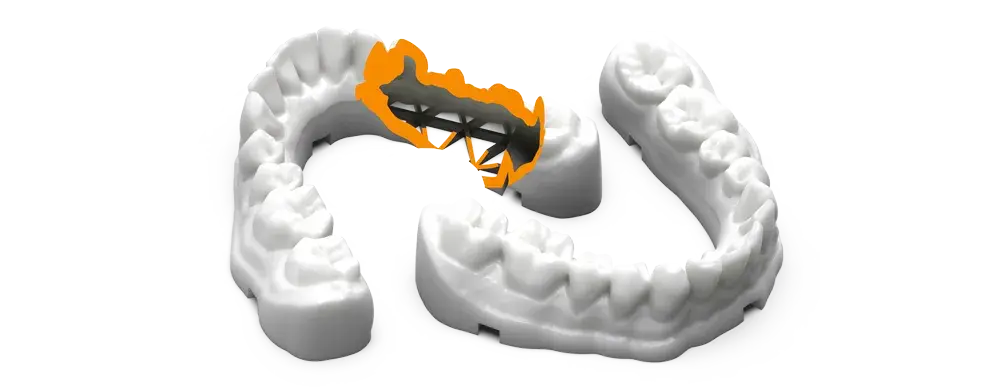

Self-Supporting Uniform Shell

- Definable wall thickness

- Gusset feature ensures self-supporting internal structure

-

Scaffold

- Optimized single vector triangulated grid

- Resists deformation during thermoforming

- Captures part ID information on down facing surface

-

High Efficiency

- Optimized single-click workflow

- Shelling, scaffold and support generation

-

Optimized Volume

- Average part weight of 8.6g

- Reduce material cost

-

3D Systems Solutions for Clear Aligner Thermoforming Tools