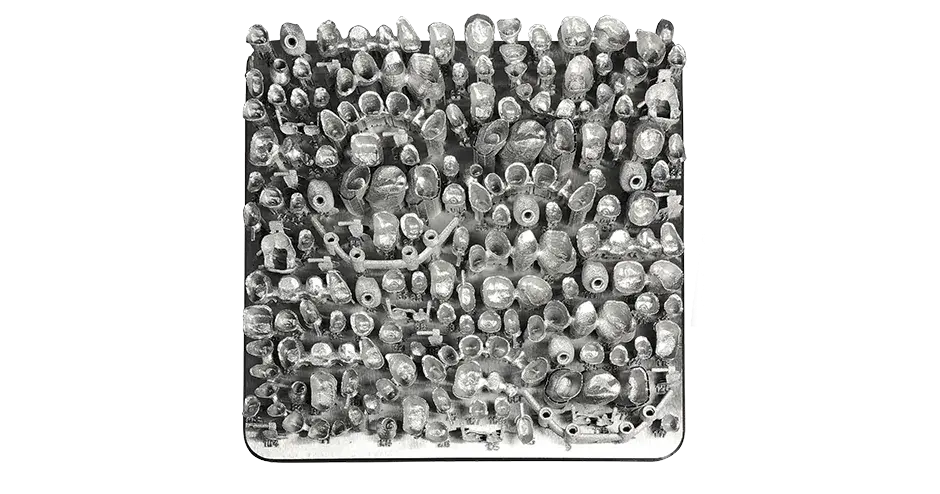

Fast Application Cycles for Increased Productivity

Drive your productivity with Metal 3D Printers for manufacturing small, dense, complex dental prostheses with excellent surface quality and short post-processing at high productivity

Metal 3D Printers for Dental Applications

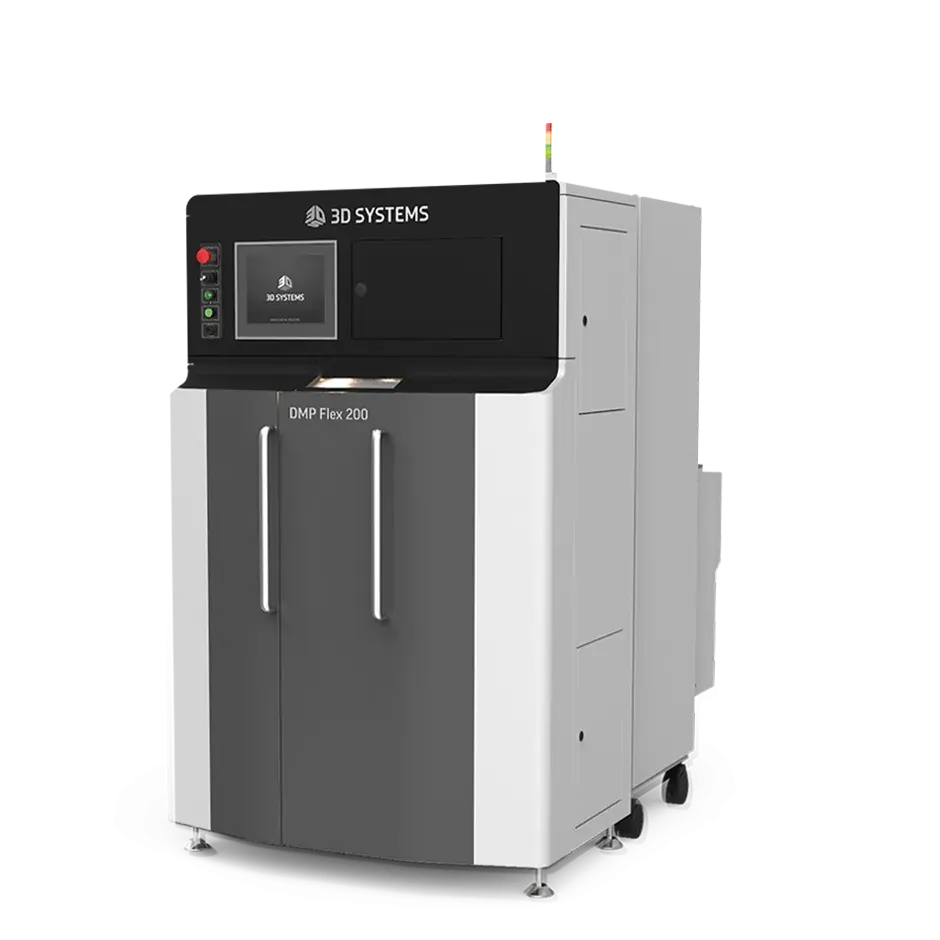

DMP Flex 200

Professional and precise metal 3D printer with 500W laser source