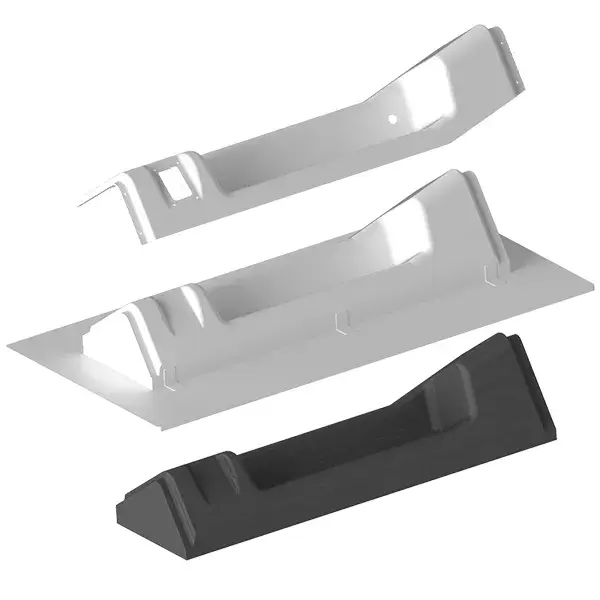

To address growing supply chain pressures, manufacturers are turning to Additive Manufacturing (AM) to create quality, cost-efficient products faster. Plastic thermoforming companies like Duo Form have discovered how to leverage large-format extrusion 3D printing using low-cost plastic pellets to gain a competitive edge. They are producing medium-to-large-sized thermoforming molds in less than half the time, and at a fraction of the cost compared to traditional mold-making methods.

Join engineering and business experts from 3D Systems and Duo Form as we dive deep into the integration that has made pellet-extrusion AM so beneficial for Duo Form, and how you can reap the same benefits in your own thermoforming processes.

In this webinar, you will learn about:

- How pellet extrusion 3D printing enables up to 10X faster mold print times, with up to 10X savings on material costs

- Duo Form specific case studies and ROI examples

- Best practices that improve AM production and mold performance such as: how to print porous molds, using infill settings for improved vacuum pulls, and more!

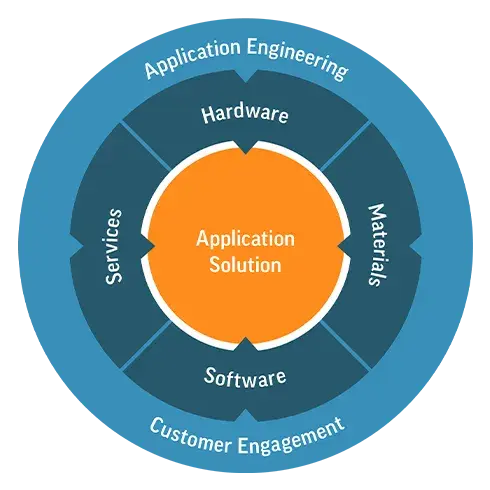

- How to select the right AM solution, including options for additive-subtractive hybrid systems