Watch Now

Watch our webinar all about the value of 3D printing in investment casting workflows, hosted by Evan Kuester, Senior Advanced Applications Engineer and member of 3D Systems’ Application Innovation Group. Discover how stereolithography (SLA) investment casting patterns fit seamlessly into foundry workflows and are advancing casting applications in aerospace, automotive, and more. Topics include:

How additive manufacturing is transforming casting applications:

- Speed – deliver robust, accurate patterns in hours

- Unlimited pattern geometries – succeed with designs that are impossible with CNC or milling

- Easy to handle – produce large, lightweight, stable, shippable patterns

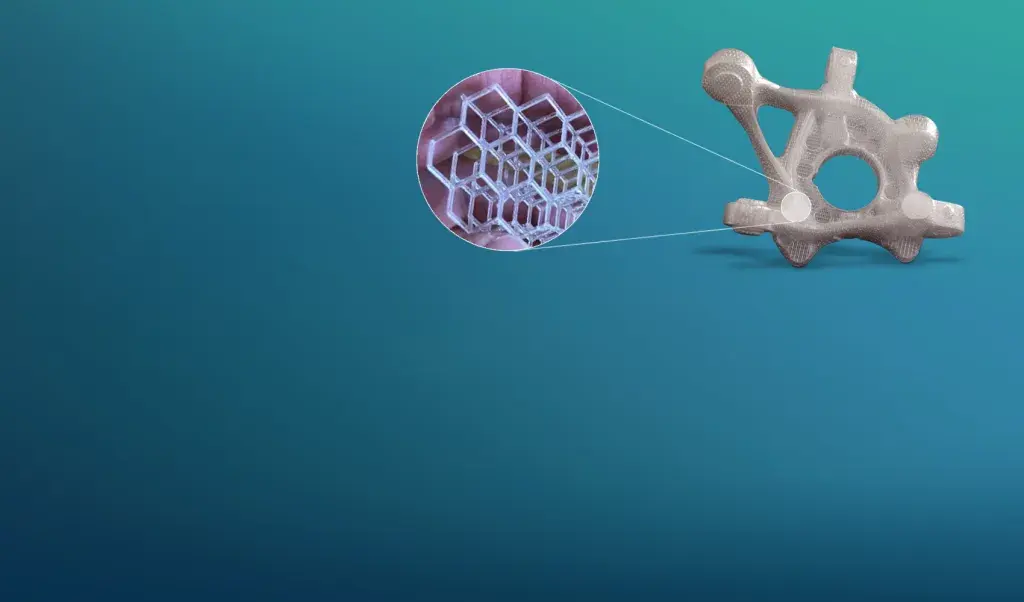

How QuickCast Diamond enables advanced performance:

- Better pattern draining with new anatomy-free, ultra-low viscosity 3D printing material

- Increased material efficiency with new QuickCast Diamond build style

- Accelerated build times (up to 20% faster) for lighter patterns (reduce weight as much as 30%)

- Larger casting patterns enabled with total casting solution for easy post-processing and joining of parts

Discover how companies like Vaupell are using QuickCast to dramatically reduce the time and cost of investment casting patterns. Watch this expert presentation and discover the opportunities additive manufacturing brings to investment casting processes.