Introducing our Volume Reducer module – a total game-changer for research and development with exotic, high-cost alloys. Requiring only one tenth of the powder, you no longer need to be restricted in experimenting with exotic alloys in your DMP Flex 350 printer. This module allows you to maximize your investment through enabling you to print small research parts and also maintain production capabilities with the same printer.

User Friendly:

Easy to use, the Volume Reducer Module functions like the standard Flex 350 module but with some added features:

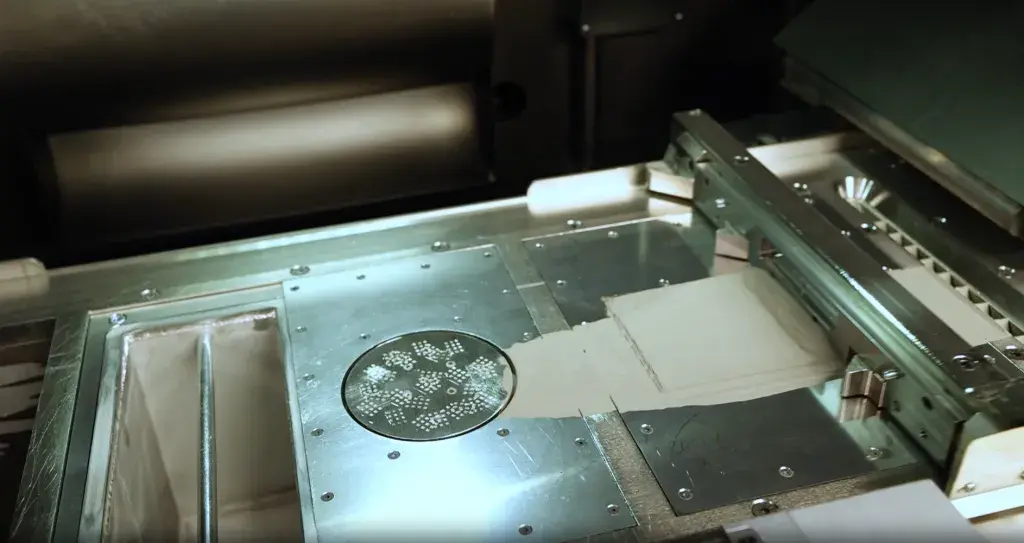

100mm build plate is perfect for printing small sacrificial parts to fine tune properties and parameters.

Use 10kg vs 100kg! Experiment with exotic, expensive alloys without having to make the significant investment to fill the machine. Reduced material usage helps save money in material/part development.

Module is fitted into the standard Flex 350 effectively reducing the build area to approximately one tenth of the regular size. When its time to scale up, the build volume reducer can easily be removed thus expanding the print area and powder feed volume back to its original size.

The incremental investment of the Volume Reducer Module empowers your team to do more. Same budget but more opportunity to fine tune density and tensile properties.

The Volume Reducer Module is perfect for experimenting with refractory alloys such as Niobium C-103, or new oxide dispersion strengthened alloys like NASA's GRX-810. Visit our material finder to discover what metal alloyrs we can offer you!

The Volume Reducer Module is designed to work with the DMP Flex 350. Available in a Single, Dual or Triple laser configuration, DMP Flex 350 is designed for flexible application use for R&D projects, application development or serial production. Visit the DMP Flex 350 page to learn more!

Explore more on how DMP powers business. Check out the latest guides and videos on investing in direct metal printing.

Explore our portfolio of printers. We have options to fit and scale with every application!

Questions? Our experts are here to support you. Get in touch today and let's get your project started!