Production-Grade SLS Workflow Solution

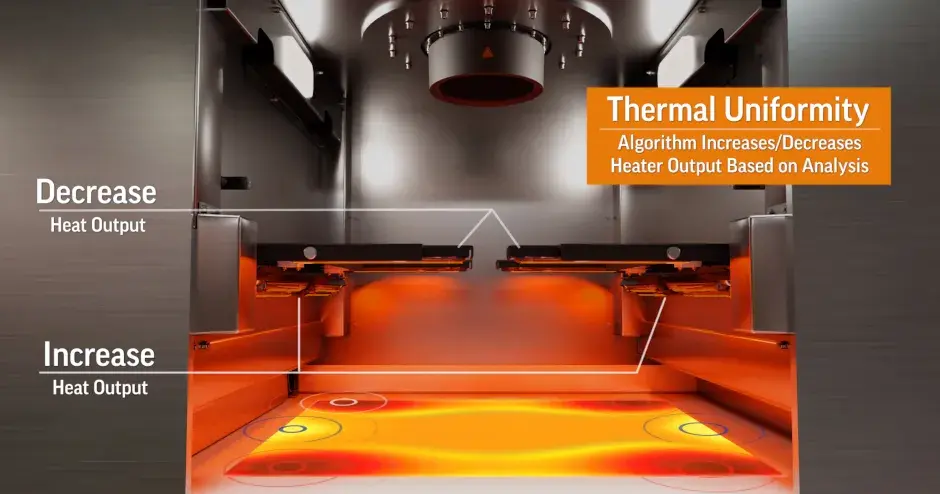

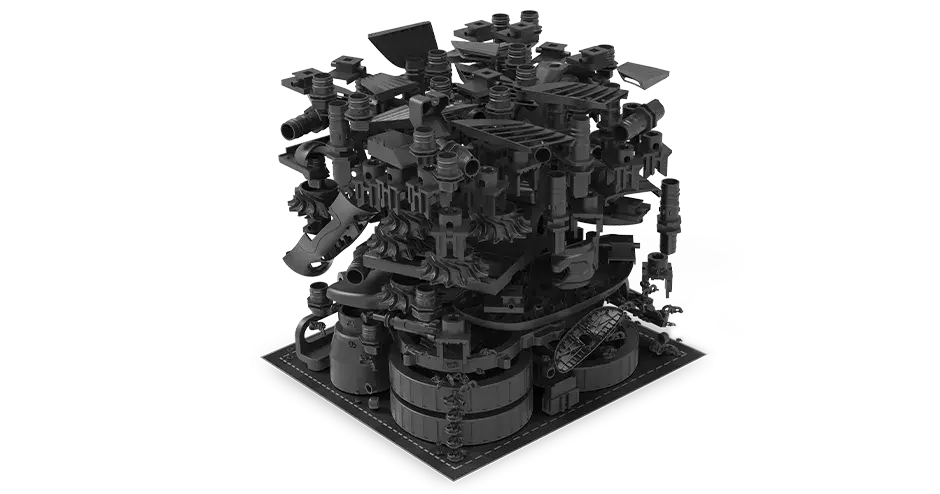

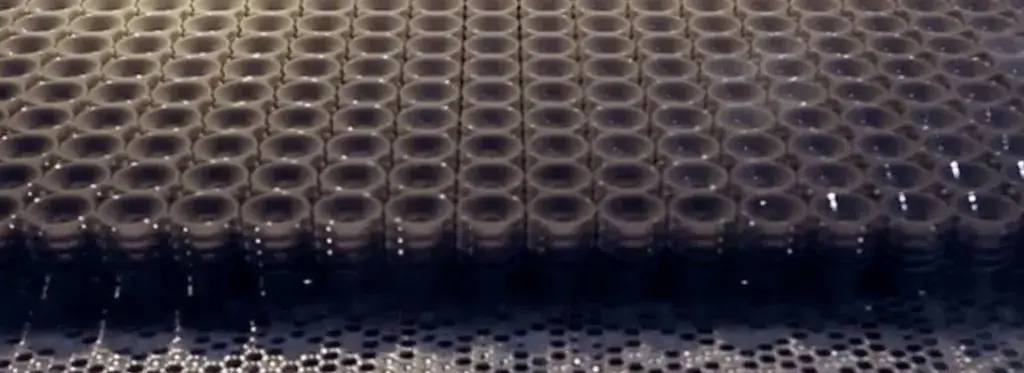

The SLS 380 is a high throughput SLS additive manufacturing solution with unprecedented levels of throughput, consistency, performance, and yield. Optimized for those who want to take the next step in integrating additive manufacturing into their factory-floor ecosystem, 3D Systems’ SLS 380 and its complementary software, material handling, and post-processing solutions answer the demand for cost-effective batch production parts.