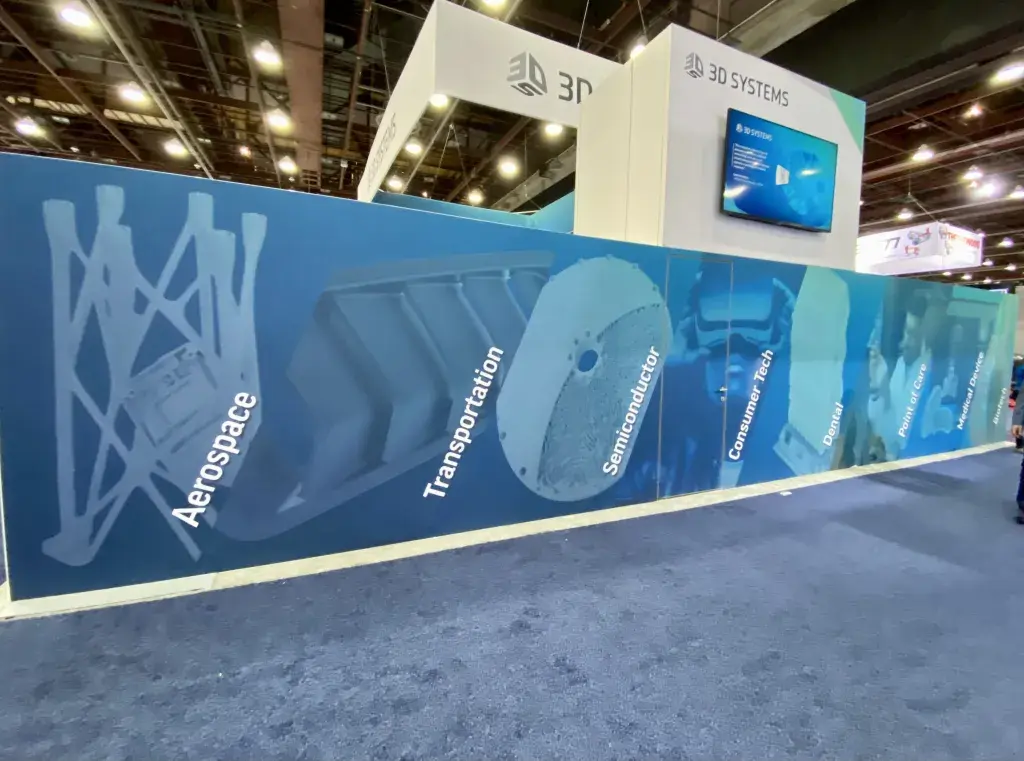

The 2022 Rapid + TCT event was held at Huntington Place in Detroit, Michigan where 3D Systems joined other additive manufacturing experts to share unique advancements in the industry. This year the 3D Systems team came to the show and highlighted how we enable customer success in industrial and healthcare markets where expert consulting and tailored solutions for the most challenging applications are required. Check out the highlights:

Introducing New Innovations at Rapid + TCT

DuraForm PAx Natural (SLS) 3D Printing Material

On the first day of the Rapid + TCT show, we were pleased to announce our latest material innovation — DuraForm PAx Natural, a novel SLS material with extreme toughness and durability. Co-developed with EMS-CHEMIE (Business Unit EMS-GRILTECH), this high-performance, recyclable PA material allows for easy and efficient print builds at a lower temperature resulting in faster machine turnaround and fewer maintenance requirements.

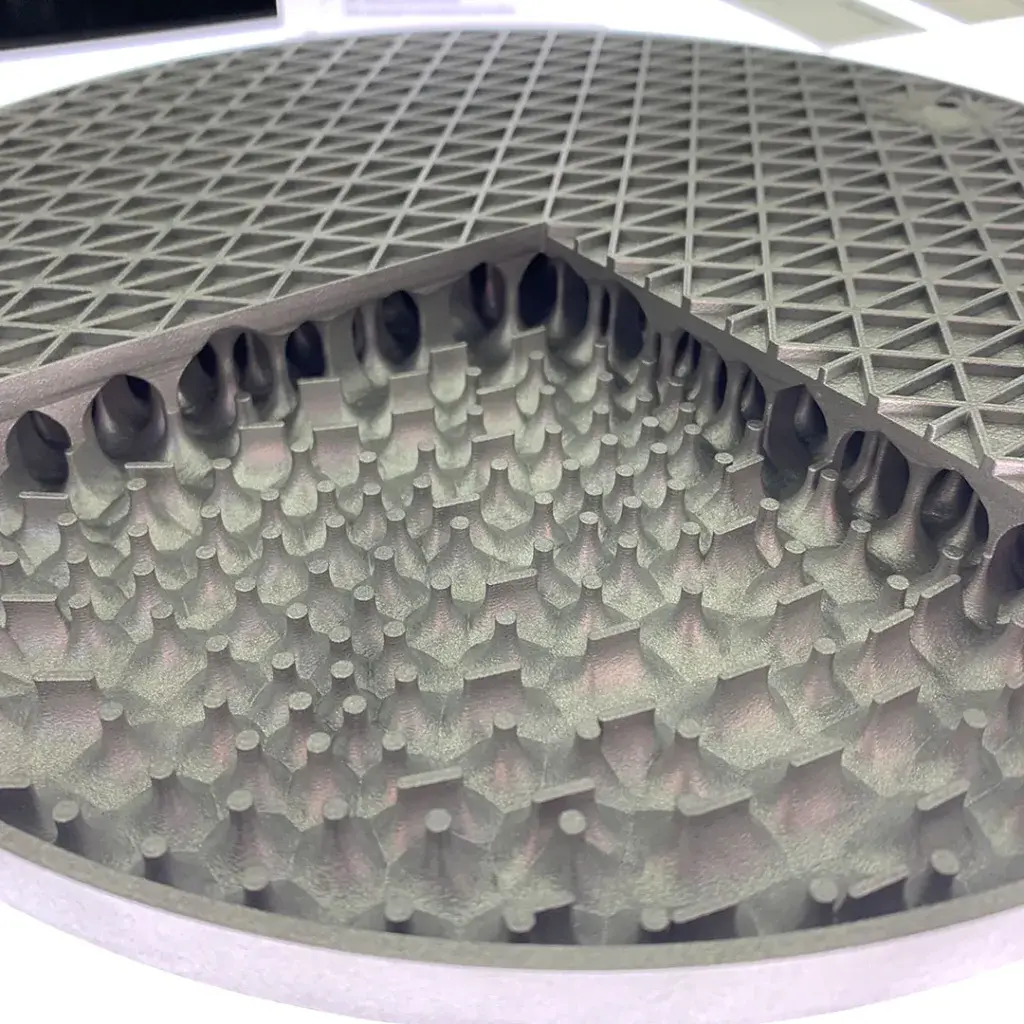

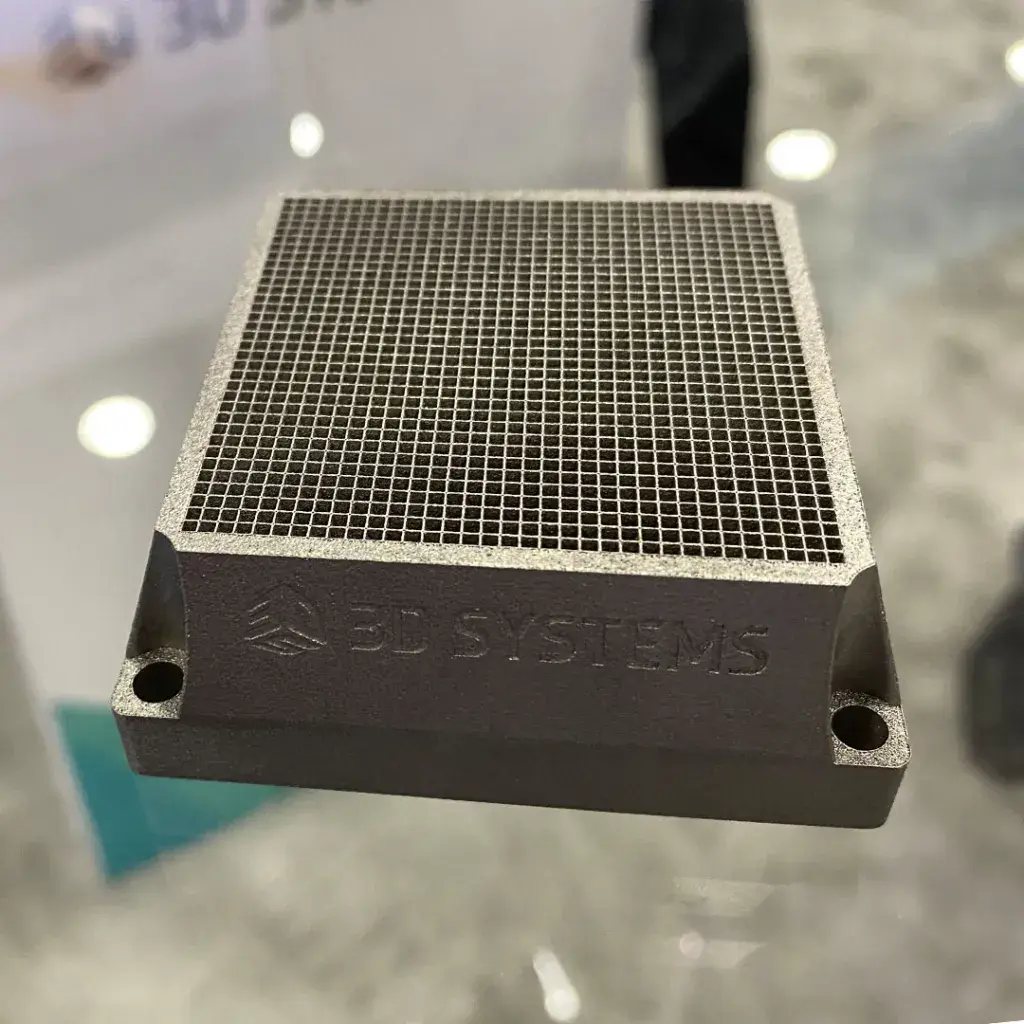

Tungsten (A) Refractory Metal and A6061-RAM2 (A) Aluminum Alloy

Many solutions and applications were showcased at the 3D Systems booth during the event, including two new additions to our metals portfolio with Tungsten (A) a high-density refractory pure metal with excellent radiation shielding capabilities and outstanding corrosion resistance, and A6061-RAM2 aluminum alloy with improved strength, ductility, and surface finish vs. traditional casting alloys for AM.

Booth Highlights - Production Additive Manufacturing Solutions for the Factory Floor

We are transforming the economics of stereolithography (SLA) for the production floor with an integrated, high productivity AM factory-floor solution, built around the new SLA 750. Check it out:

Changing the Traditional Manufacturing Landscape with Titan Robotics Ltd., a 3D Systems Company

The leader in pellet extrusion 3D printing technology, Titan Robotics Ltd., a 3D Systems Company joined us at the event, and Applications Engineer, Nabi Ajoff walked through their solutions and capabilities.

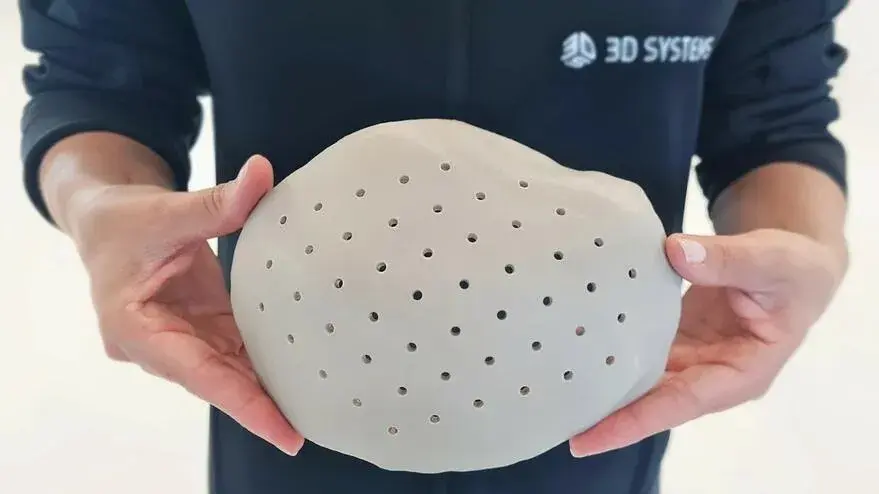

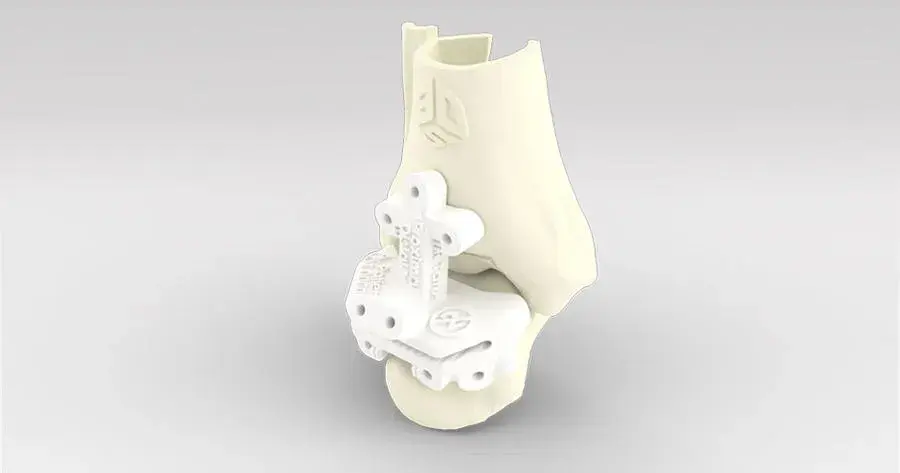

Expertise & Technology with Kumovis’ PEEK Printing Solutions

Kumovis Co-founder and Co-CEO, Stefan Leonhardt, introduced newcomers to the PEEK printing technology which focuses on decentralizing the production of medical implants and more.

NextDent by 3D Systems

3D Systems’ Application & Business Development Director of Dental, Stijn Hanssen walked through our NextDent by 3D Systems materials and solutions.

3D Systems’ Additive Manufacturing Innovations

AM Challenges that Persist: 100+ years of Additive Manufacturing Expertise and Insights

During the event, our Chief Technology Officer, Dr. David Leigh joined the panel of AM experts moderated by Sheku Kamara and Carolyn Conner Seepersad, PhD. The team of experts identified with today’s persistent technical and adoption challenges that are critical to AM advancement and engaged in a conversation on past experiences sharing how they broke barriers into innovative technology and identifying what’s to come for the next major breakthrough.

3D Systems’ Chief Technology Officer for Additive Manufacturing, Dr. David Leigh, is joined by other industry experts sharing insights on challenges, experiences, and key opportunities for the next major breakthrough in AM.

Current State of 3D Printing at Point-of-Care Future Outlook: Implementation, Optimization, and Challenges Town Hall

In a Town Hall event during Rapid + TCT, 3D Systems’ Vice President, Portfolio and Regulatory, Ben Johnson participated in a panel discussion covering the current and future state of 3D printing at the point-of-care. Ricoh’s Sarah Rimini was the panel moderator and Ben joined other industry experts Matthew Di Prima, PhD of the FDA, and Justin Ryan, PhD of Rady Children’s Hospital San Diego.

3D Systems’ Vice Presidents, Portfolio and Regulatory, is joined by other industry experts at RAPID + TCT 2022.

Bridging the Biomaterial & Bioprinting Gaps Facing the Industry

3D Systems’ Vice President, of Regenerative Medicine, Katie Weimer was a panelist among other industry experts during a fascinating industry partner presentation at the SME Zone Theater. Katie highlighted the techniques 3D Systems is using to advance biomaterials and bioprinting solutions, addressing our broad spectrum of bioprinting applications and how we are accelerating growth into biomedical and pharmaceutical research labs.

Jared Matthews of Advanced Regenerative Manufacturing Institute (ARMI), moderated the panel discussion among industry leaders Brian J. Hawkins PhD from Pluristyx Inc., Henry Kim from Dimension Inx, and Adam Feinberg PhD from FluidForm Inc.

Driving Speed and Efficiency in Industrial and Healthcare Applications

During the trade show, our team of application engineers shared a variety of on-site application demonstrations ranging from aerospace, automotive, semiconductor, turbomachinery, healthcare, dental, and bioprinting. Other notable panel presentations that took place during the event were with Oral Surgeon Dr. Daniel B. Spagnoli and Chief Dental Technician of Centric Dental Lab, Tyler Britt on digital dental implantology highlighting our NextDent 5100 dental technology. And last but not least 3D Systems' Vice President, Aerospace & Defense Segment, Dr. Mike Shepard, joined Newport News Shipbuilding's Manager Principal Engineer & Deputy Chief Engineer, Additive Manufacturing, John W. Ralls, Ph.D., PE, for a discussion on The Role of Additive Manufacturing in Heavy Industry. We encourage you to visit our Instagram and LinkedIn pages to view snippets of these demonstrations.

We want to extend a huge thank you to all of the attendees, exhibitors, panelists, partners, and customers that were able to attend this year’s event. Not able to attend? We invite you to contact our team for more information or meet with us at one of our upcoming events.