Inside the Future of Orthopaedic Innovation: A Conversation with 3D Systems’ Ben Johnson

To watch now click on your platform: YouTube | Spotify | Apple

In this podcast episode, TJ Halvorson of Orthopedics this Week (OTW) sits down with Ben Johnson, Senior Vice President MedTech at 3D Systems. His journey from chemical engineering into advanced additive manufacturing offers a compelling look at how innovation happens at the intersection of materials science, clinical need, and cutting‑edge 3D printing.

Ben began his career developing drug‑eluting stents and transcatheter heart valves, where he first encountered the limitations of traditional testing tools and the need for patient‑specific solutions That experience ultimately introduced him to the transformative capabilities of 3D printing, bringing him to 3D Systems in 2014, where he now helps shape the future of medical devices.

The Evolution of Additive Manufacturing in Orthopedics

The conversation traces the arc of additive manufacturing back to 3D Systems’ foundational invention of stereolithography in 1983, a milestone still central to its innovation DNA. Today, the company's healthcare portfolio spans advanced materials including titanium, PEEK, and cobalt chrome, each supported by end‑to‑end medical device manufacturing workflows.

Learn more about 3D Systems’ medical manufacturing capabilities.

Ben highlights a key market shift: titanium has moved from being overshadowed by PEEK to now capturing roughly 50% of the spine market, driven by its strong osseointegration when 3D printed into porous, bone‑like structures. This mirrors broader industry trends toward materials that improve fixation, healing, and long‑term outcomes.

Emerging Technology: HA‑Coated PEEK and Next‑Generation Osseointegration

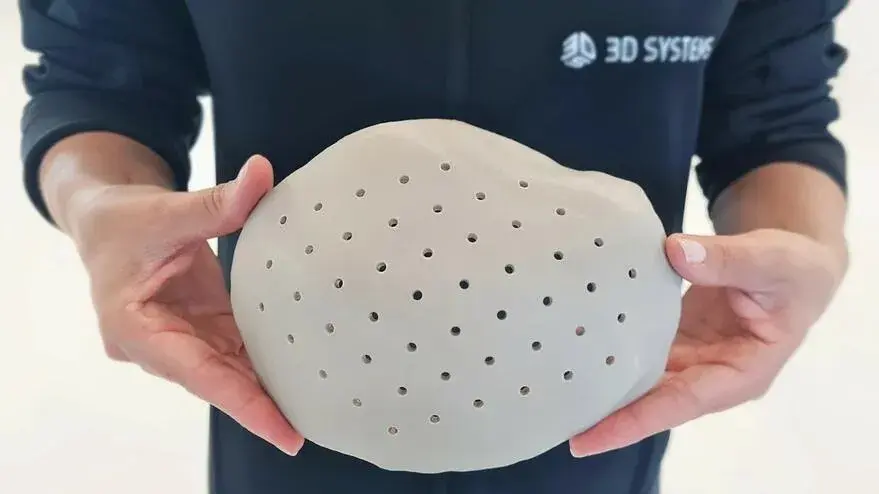

A major focus of the discussion is the rapid advancement of hydroxyapatite (HA) enhanced PEEK implants, which blend PEEK’s mechanical benefits and radiolucency with biologically active surfaces that promote bone bonding.

Ben references a recent 3D Systems white paper, Redefining Osseointegration: How Additive Manufacturing Unlocks Osseointegration with PEEK Architectures and companion The Future of Implants: 3D Printed Porous HA PEEK Cages showing promising osseointegration in both cortical and cancellous bone, signaling a strong trajectory for this technology in the next decade.The Reality of Personalization and Point‑of‑Care Manufacturing

Ben offers a candid perspective on point‑of‑care 3D printing, noting that while the concept is appealing, hospitals face significant regulatory, cost, and workflow challenges. Instead, hybrid models, where certain activities remain centralized while hospitals perform last‑mile customization are gaining traction.

Partnering From Concept to Commercialization

One of the most valuable insights Ben shares is how 3D Systems partners with companies at every stage, from early‑stage startups with only a sketch, to global OEMs with complex product portfolios. Their support spans:

- Concept development & design for additive manufacturing

- Prototyping and clinical evaluation

- Regulatory guidance

- Full‑scale manufacturing at ISO facilities

- Technology transfer for companies ready to bring production in‑house

Explore 3D Systems’ full healthcare ecosystem.

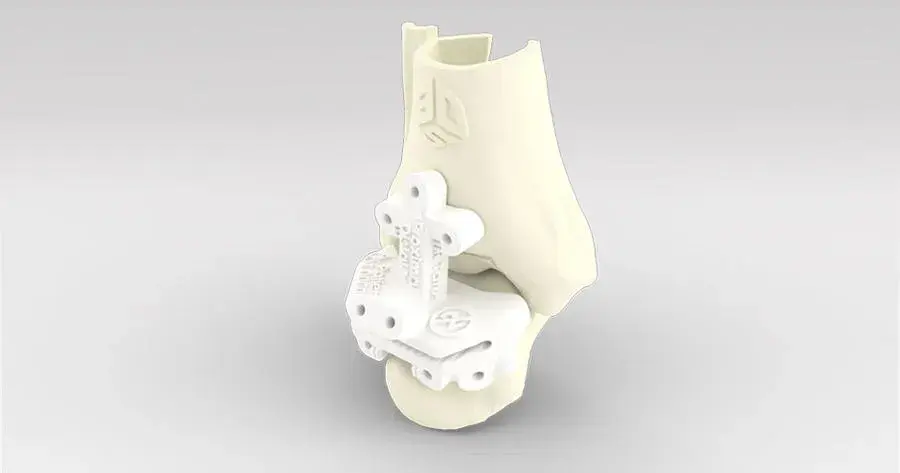

Ben emphasizes that the mission isn’t just to print parts, it’s to solve unmet clinical needs. Whether improving osseointegration, supporting oncology reconstruction, enabling faster virtual surgical planning, or building resilient supply chains, 3D Systems acts as an innovation partner helping bring devices from concept to commercialization.

Why This Matters for the Future of Orthopedics

As orthopedic companies race to meet surgeon expectations for better outcomes and more personalized treatment pathways, additive manufacturing is becoming a strategic advantage, one that requires deep expertise in materials, design, workflow, regulation, and clinical integration.

This episode offers a rare look inside that ecosystem and the pivotal role a partner like 3D Systems plays in accelerating next‑generation medical device innovation.

If you’d like help transforming your orthopaedic ideas into scalable, regulatory‑ready solutions, contact us here.

To watch now click on your platform: YouTube | Spotify | Apple

Heading to American Academy of Orthopaedic Surgeons (AAOS) 2026 in New Orleans? Schedule time with one of our specialists at booth 2539.