As part of the NextDent® Jetted Denture Solution, 3D Sprint® is an easy-to-use software solution designed for preparing and optimizing CAD and polygon data. Built with affordability, seamless integration, and an intuitive interface in mind, 3D Sprint plays an integral part in helping dental labs bring digital denture production to the next level as part of the NextDent Jetted Denture workflow.

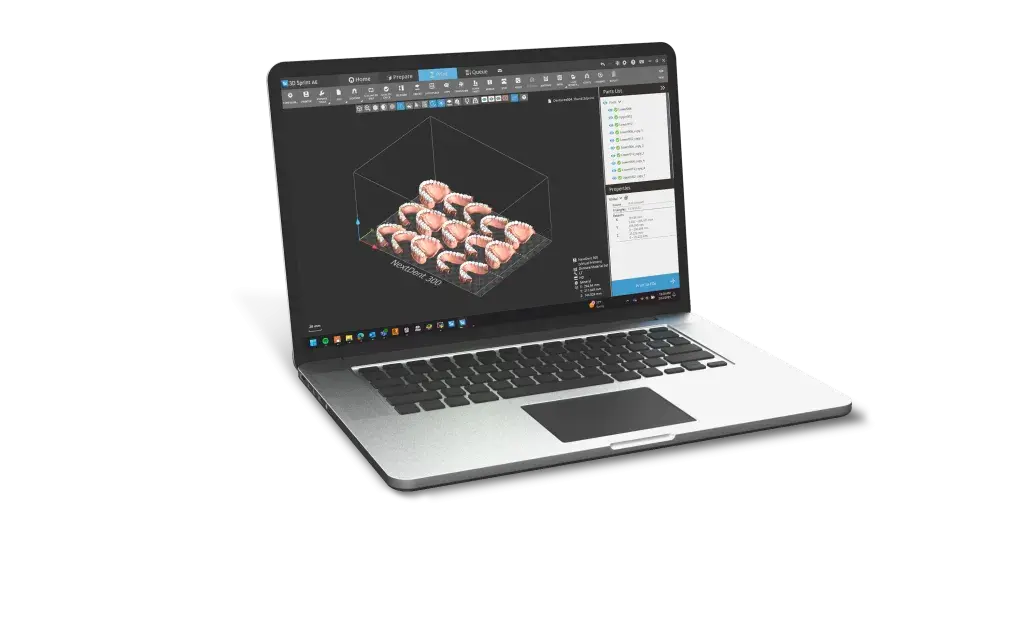

With 3D Sprint, dental lab technicians can prepare both teeth and gum design files to print as one seamless, monolithic denture. Further reduce labor time with one-touch, precise nesting for optimized positioning of parts to maximize parts per print. Precise nesting ensures each print is efficient, accurate, and ready for production with minimal adjustments.

A new feature of 3D Sprint, specific to the NextDent 300 as part of the Jetted Denture Solution, is flush-to-surface engraving. Compared to traditional engraving or labeling methods for patient parts, flush-to-surface engraving saves dental technicians labor time and creates a smooth surface to avoid any irritation to the patient commonly found with traditional engraving methods. Engravings are printed into the gum material of the denture with the teeth material shades for discrete labeling of the dentures.

By helping streamline the digital denture workflow, 3D Sprint helps labs save time and reduce labor costs. Its optimized data management, integration with CAD systems, and powerful slicing engine make production more predictable and scalable. When paired with the NextDent 300 for Jetted Dentures, the software ensures optimized print runs and smoother workflows.

Beyond dentures, 3D Sprint also integrates seamlessly with the NextDent 5100 and other 3D Systems printers, supporting a wide range of dental applications including models, splints, and surgical guides.

Take the next step in transforming your digital dental production with 3D Sprint.