-

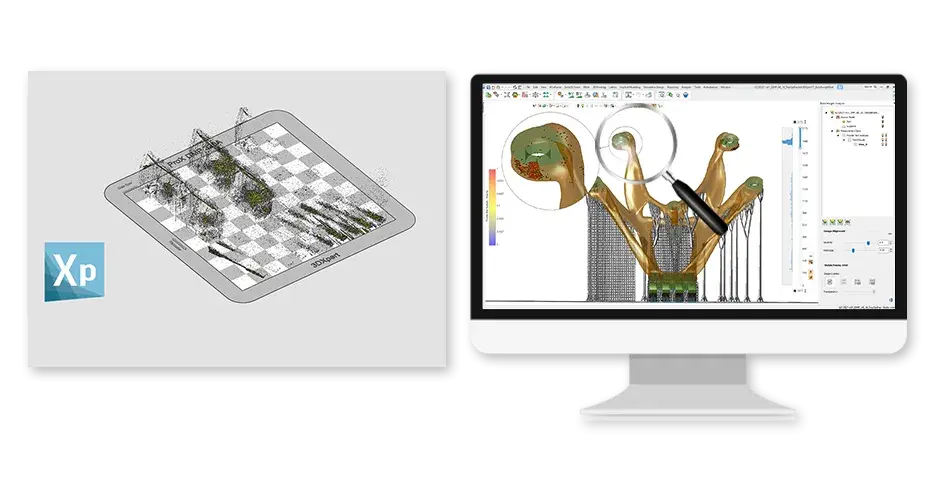

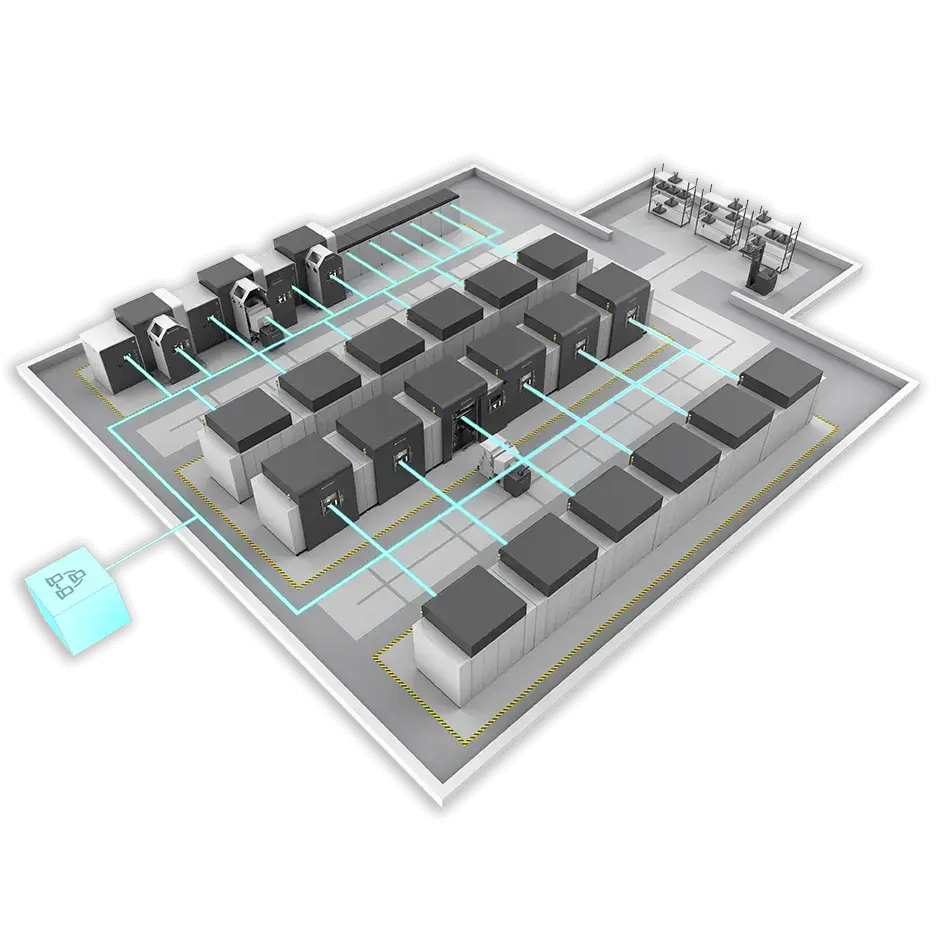

Design

The 3DXpert all-in-one software solution to design and prepare the build file

-

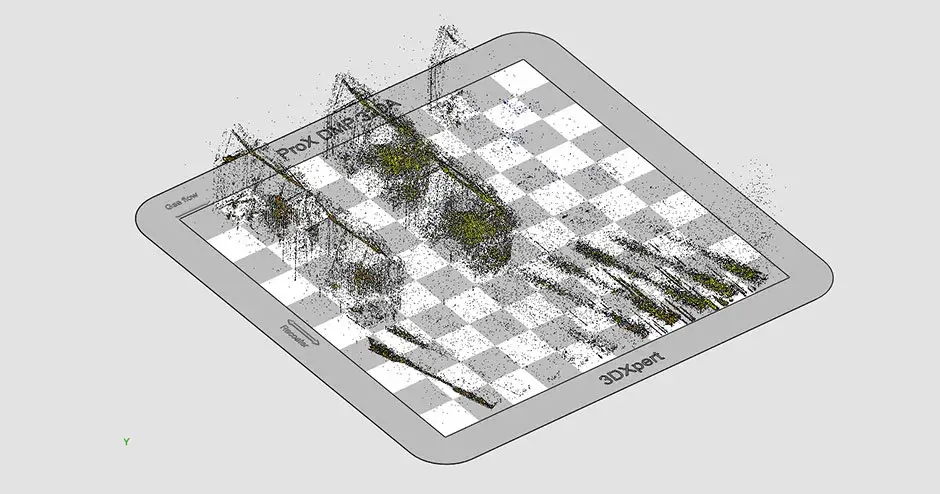

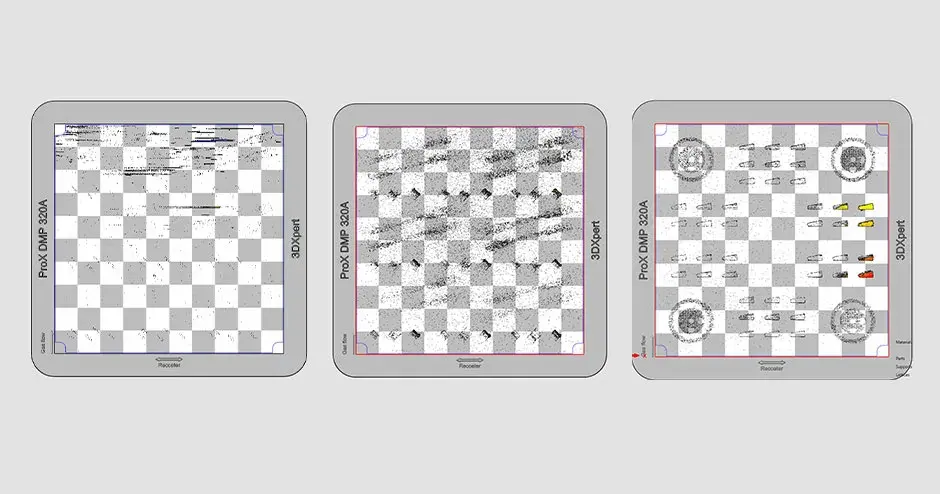

Simulate, Optimize

The Build Simulation module to simulate & optimize design before printing

-

Print

-

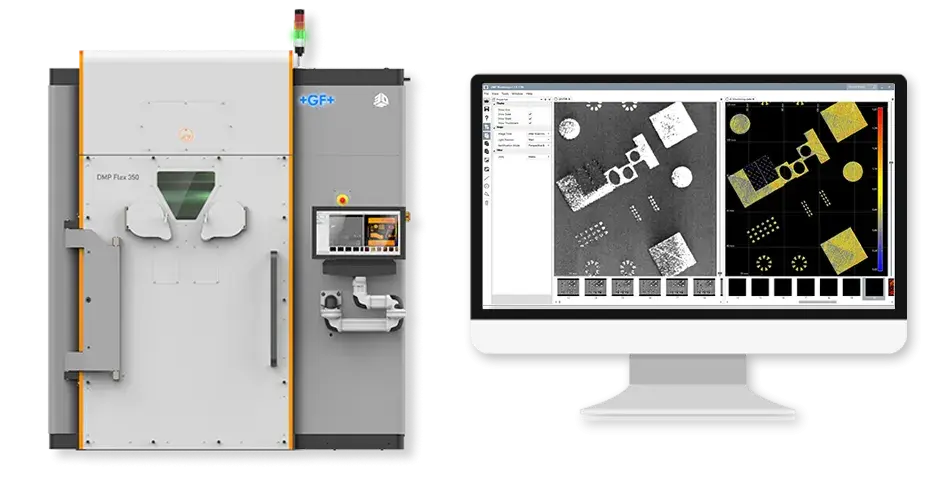

Diagnose

The Build Insight module for advanced diagnosis of the build process for build design optimization and printer health monitoring

-

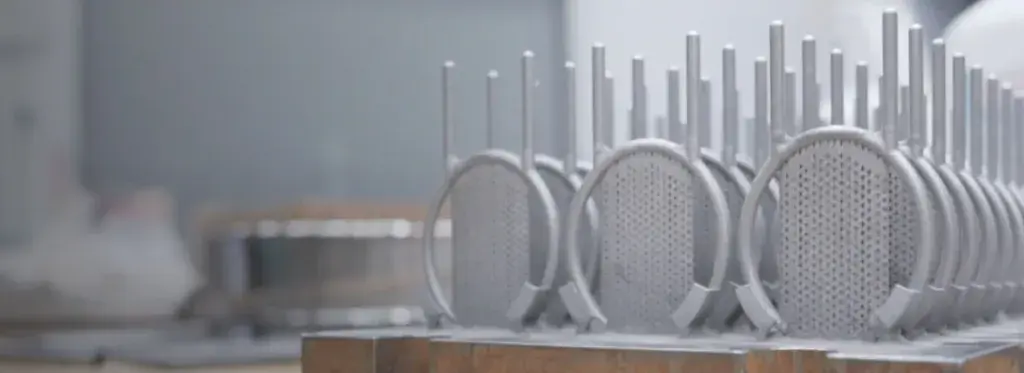

Post-processing

Powder removal, heat treatment, HIP, EDM, support removal, machining

-

Standard Quality Assurance