Please submit this form to watch the recording:

Save production time and deliver designs with extended geometric freedom

Successful jewelry design requires creativity, quality, and the ability to produce high-fidelity patterns. 3D Systems’ advanced 3D printing solutions accelerate your time-to-market and give you a competitive advantage in high-volume production and mass-custom jewelry making.

Fitting into your standard manufacturing workflow - from finely detailed prototypes, to lost wax casting and mold making, our wide range of 3D printing solutions addresses all jewelry design styles and production challenges.

Join our experts to explore how our next generation 3D printing solutions ensure perfect quality and reliability every time, reduce cost and time-to-market, and help you achieve new levels of jewelry design and productivity.

Topics covered in this webinar:

- Insights into jewelry making challenges

- Benefits of 3D printing within the jewelry design to manufacturing workflow

- Focus on new capabilities with the MJP 300W next generation wax patterns 3D printer and expended range of wax materials with for direct jewelry casting

- Examples of jewelry casting use cases

Register to participate in this expert-led webinar, covering all the key success factors for advancing jewelry manufacturing with 3D printing.

About Our Experts

|  |

| Michael Simmons | Rob Noce |

| Manager, Application Innovation Group – Berkeley 3D Systems | Product Manager, Jetting Technologies 3D Systems |

| Michael Simmons is an advanced application engineer at 3D Systems and manages the Application Development Lab in Berkeley, CA, as part of the broader Application Innovation Group. Michael has extensive experience in expanding the use of 3D printing to a wide range of markets, including, healthcare, consumer technology, and lifestyle applications. In recent years, his focus has been on developing, and scaling mass complex manufacturing workflows in collaboration with industry leaders including Meta and TE Connectivity. | Rob Noce is the Product Manager for Jetting Technologies at 3D Systems. He is responsible for driving product strategy in our MultiJet printing (MJP) portfolio. He has been with 3D Systems for eight years, serving as Director of Product Development in MJP and CJP technologies prior to his role as Product Manager. |

Featured Products

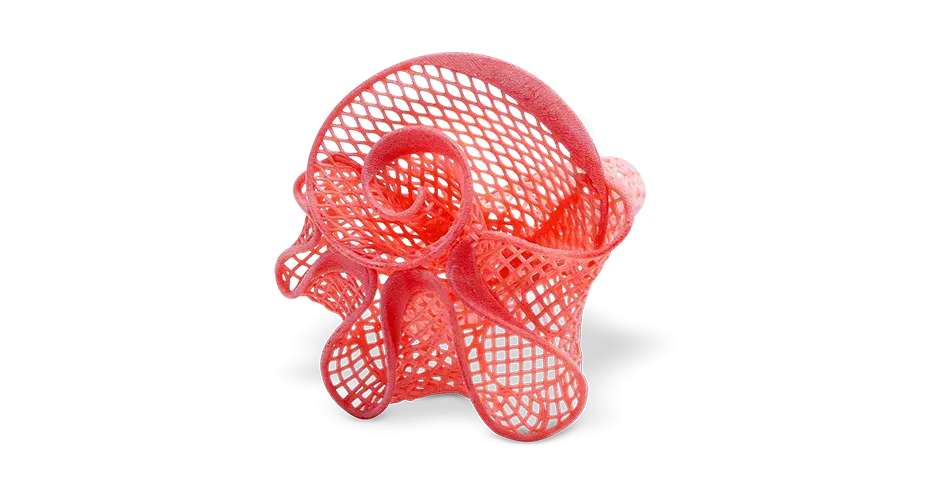

VisiJet Wax Jewel Ruby (MJP)

Durable, flexible, and dimensionally stable 3D printed pure wax casting patterns

VisiJet Wax Jewel Red (MJP)

Durable and flexible, 100% wax for intricate jewelry casting patterns

VisiJet M2 CAST (MJP)

Durable, 100% wax for precision jewelry metal casting patterns