About Medical Device Solutions

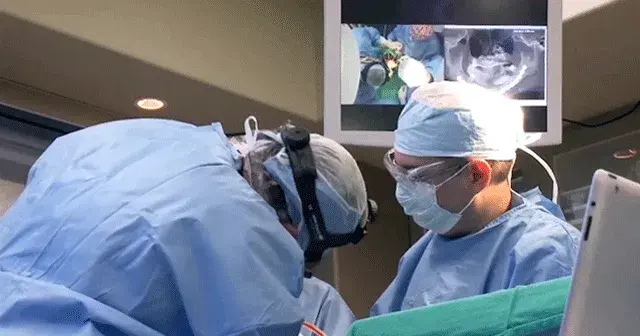

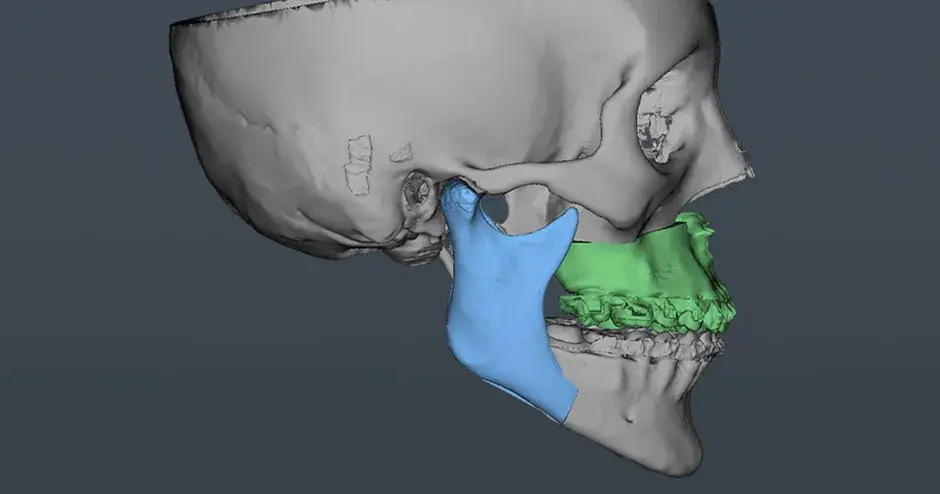

The innovative spirit that began when our founder and CTO Chuck Hull invented 3D printing in 1983 continues to be the common thread in everything we do in healthcare. Since we began collaborating with medical device manufacturers to use additive manufacturing to help transform healthcare, we have pioneered virtual surgical planning solutions. In the last 10 years, we have worked with surgeons to plan over 140,000 patient-specific cases. Plus, we were the first to introduce full procedure simulation and patient-specific summation.

We have also manufactured more than two million implants and instruments for 100+ CE-marked and FDA-cleared devices. With world-class, FDA registered, ISO 13485-certified facilities—located in both North America and Europe—we offer unparalleled expertise in 3D printing, engineering, quality control, and healthcare regulatory requirements. Our experience in designing and developing new products, ensuring precision production, and navigating commercialization processes enable our partners to bring revolutionary medical devices to market faster than ever before.

"3D Systems helped educate us on the additive process and worked with us to iron out our process beyond just the printing. We had a lot of open dialogue, and that communication was key to our success."— Director of Product Development at NuVasive