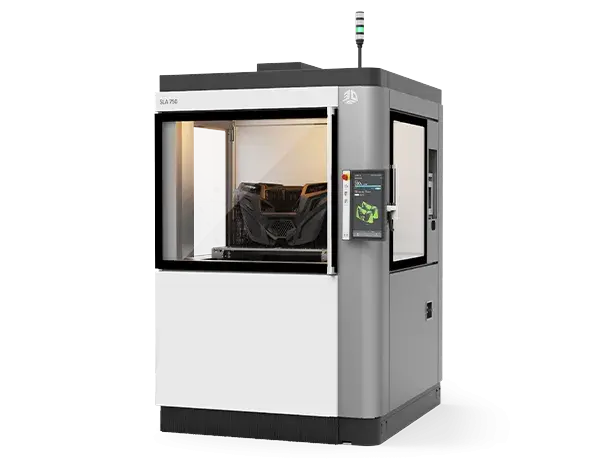

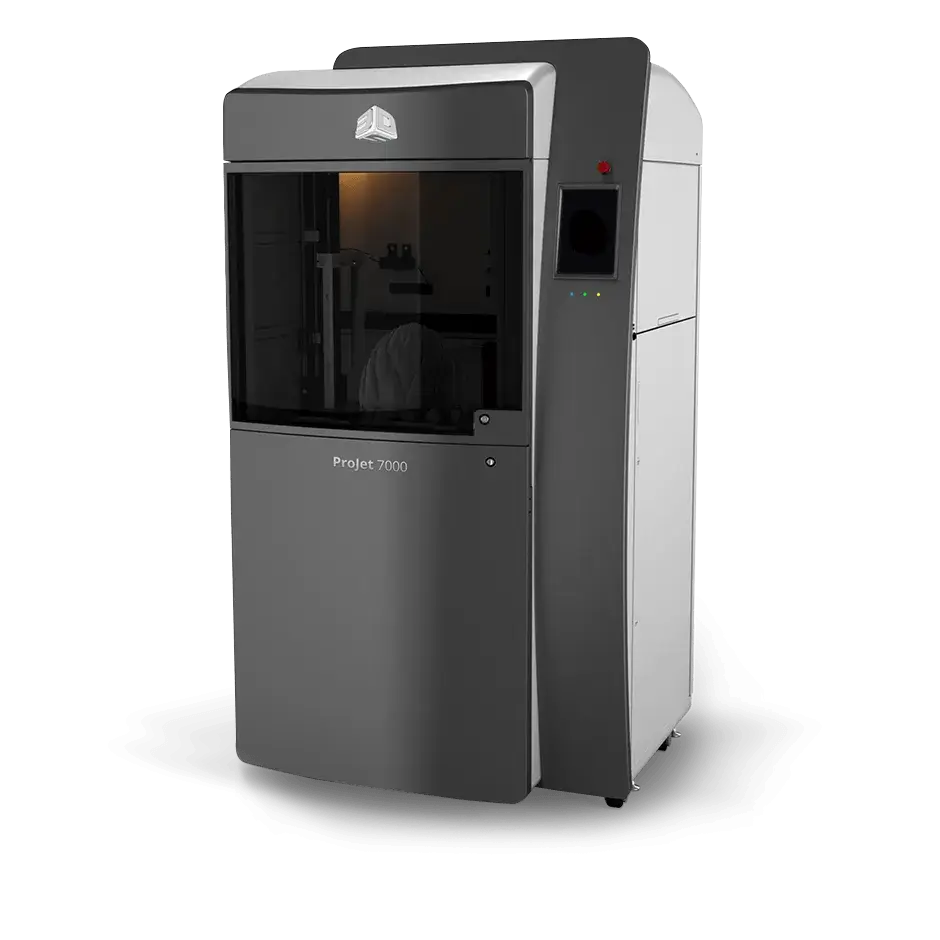

Production-Grade SLA Workflow Solution

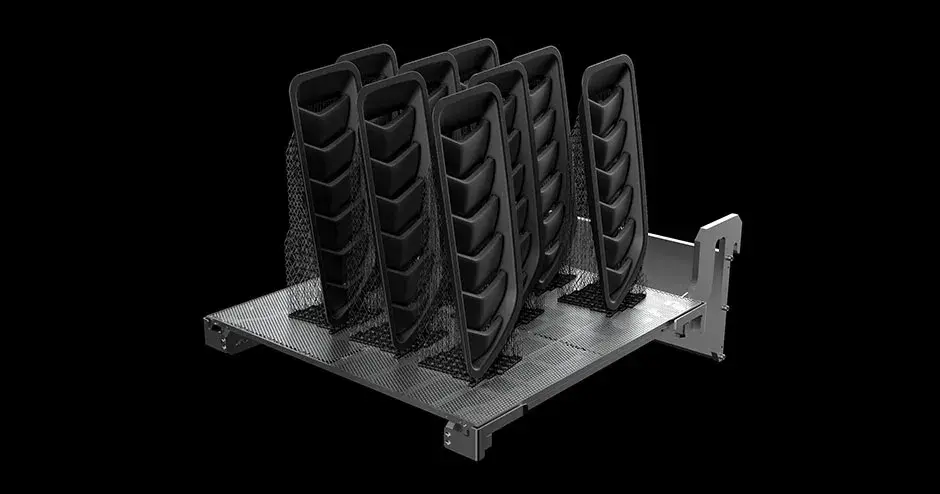

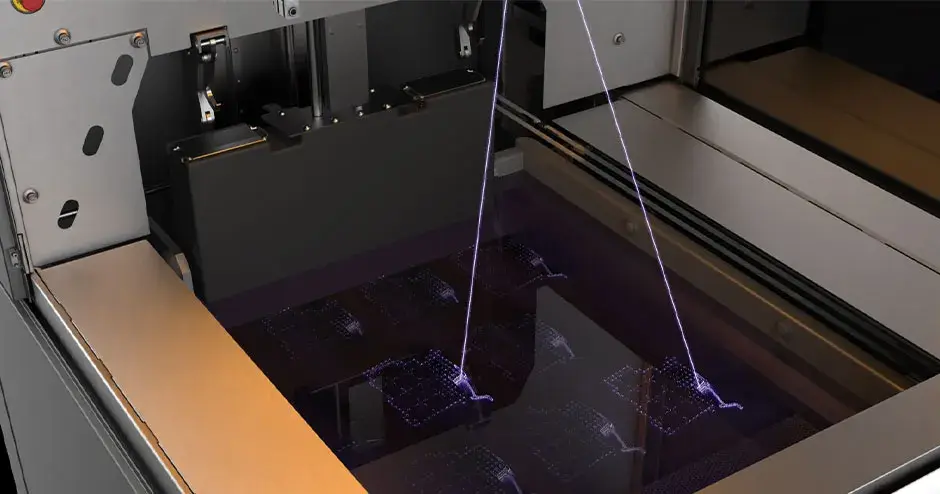

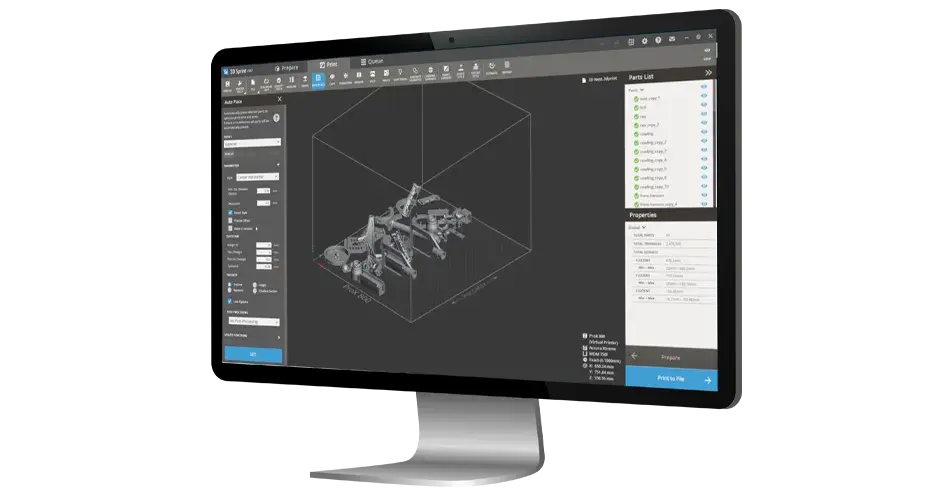

The SLA 750 solution delivers a breakthrough in additive manufacturing productivity, speed, reliability, and automation from the leading innovator in stereolithography (SLA) 3D printing. A full solution is comprised of the SLA 750 family of large-format 3D printing systems, advanced production-grade photopolymer materials, the PostCure 1050 post-processing system, and the Oqton cloud-based, end-to-end manufacturing operation system.