By: Scott Turner

Welcome to part two of the “Material Information” blog series. If you missed part one by David Cullen, it is a great resource on SLS production materials. Today’s topic takes a look at another versatile technology in 3D Systems’ portfolio: stereolithography (SLA), and the unique materials and methodologies that are available for production applications.

I have been part of the 3D printing industry since the very early days, and now have over 30 years of firsthand experience using and developing this technology. I consider myself in good company at 3D Systems, where I have had the privilege of spending my career alongside Chuck Hull, also known as the man who started it all with the invention of 3D printing (specifically stereolithography (SLA), the subject of this blog) in 1983.

Since its introduction, SLA has been considered a gold standard for accuracy in 3D printing, and remains such to this day. In addition to system and software improvements that have been implemented over the years, a major capability shift has occurred in the realm of materials. The growth in the range of SLA material options has arguably played the biggest role in expanding the range of addressable applications, and the material portfolio continues to grow.

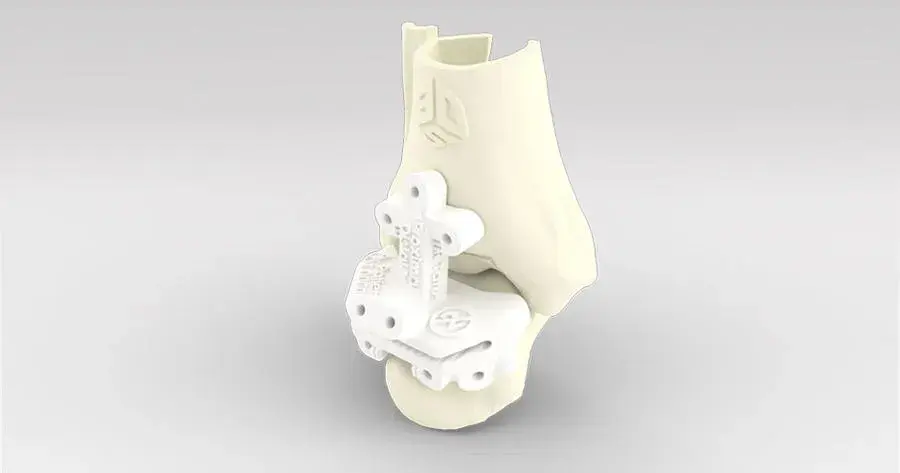

SLA has found loyal users within the healthcare market, due to its precision and the biocompatibility of select materials, as well as in the automotive market, due to its stiffness and large build sizes, among other properties. The volume of SLA print platforms is also attractive to aerospace and energy customers, who are drawn to the casting capability enabled by our SLA QuickCast methodology.

Before I throw too many things at you at once, let’s take a step back and look at what’s possible with SLA materials today that makes it a good match for production, and then shift gears to discuss a few specific options. If you have questions at any point, please don’t hesitate to reach out. We are here to be a resource for you and love doing it, so please don’t be shy.

Why is stereolithography a good choice for production applications?

With the recent advancements in materials science, photopolymer mechanical properties have improved dramatically. What this means in plain language is “photopolymers can now do the work” for production applications. Using 3D printing (AKA additive manufacturing (AM) or digital production), it is now possible to manufacture complex plastic photopolymer parts without time, costs, and design limitations of thermoplastic tooling. These new photopolymers have the same performance and stability through the entire part lifecycle, which has been the exclusive domain of thermoplastics until now.

With the advancements that have been made in materials science, photopolymers are catching up with thermoplastics.

This means you can now go beyond the aesthetic and performance of plastic parts you are accustomed to getting with traditionally molded parts. This is surprising to those who have maintained a head’s down focus on traditional manufacturing methodologies, but it should also signal an amazing opportunity to innovate faster, get to market sooner, and depending on your product and business, even restructure your supply chain for dramatic improvements to your bottom line. If you want to try out AM as a one-off or ad hoc option, 3D Systems On Demand offers parts manufacturing for single parts and volume orders, which is a great way to get your feet wet with additive.

Before I go into the key production materials and methods I recommend for SLA, I’d like to quickly point out that the benefits of digital production span all 3D printing technologies. 3D Systems offers a full suite of print technologies, and we are interested in connecting you with the solution that best matches your application. If that’s SLA, I’ll feel really good about writing this blog. If it’s something else, we’ll help you find it.

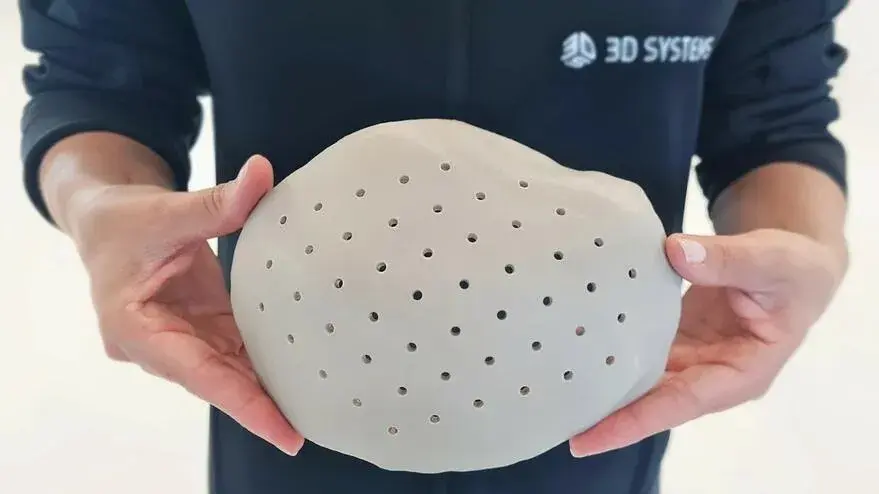

3D printing photopolymer casting patterns for indirect metal part production (QuickCast)

A major value of SLA systems is the build volume they offer, which enable large parts to be built singly, or batched production of small parts. When paired with the QuickCast SLA build style, this build volume and/or capacity offers a new way to achieve cast metal parts that are large, more complex, and require no tooling. QuickCast patterns enable the manufacturing of metal parts with the complexity of computer-generated design. A large share of these new lightweight structures cannot be produced with tooling. QuickCast offers a lower cost option than Direct Metal Printing for many of these advanced structures.

The QuickCast build style was invented in the 1990s, and through continuous improvement is now in its third generation of optimization performance. QuickCast patterns seamlessly integrate into traditional foundry workflows to produce cast metal parts. If this is your first time hearing about QuickCast or the idea of using 3D photopolymer printing for complex investment casting patterns, I am honored to be the one to introduce you to this world of opportunity.

The QuickCast methodology is good for multiple reasons, not the least of which is the huge cost savings realized from not building a tool. Beyond the economic impact, 3D printing investment casting patterns allows the final part to be more complex than tooling would otherwise allow, which invites greater innovation to improve performance of the part or system. The result of these improvements typically also offers an economic gain over the lifetime of the part.

There will of course be times where a project’s scale validates the expense of tooling, but QuickCast makes tooling optional and production quantities flexible, which is a wonderful freedom to have. In aerospace, many customers have used the complexity allowances of SLA casting patterns to create lighter weight parts that contribute to increased fuel efficiency, and have proven time and again the value of bringing an open mind not only to design, but to execution.

We offer several different material options optimized for QuickCast pattern production, including our popular Accura® CastPro and Accura® CastPro Free. These materials produce highly accurate and stable casting patterns with easy post-curing to minimize part finishing time. They are also compatible with both ferrous and non-ferrous metal types.

Clear 3D printing options

SLA offers a number of clear 3D printing materials with various properties, including options with high temperature resistance, biocompatible formulations, and even ones clear enough to replace glass or polycarbonate parts.

Clear 3D printing materials are amazing for visualization models, prototypes, and assemblies, and they have also proven to be beneficial in eggshell molding applications. The reasoning is intuitive enough: seeing into the volume you are filling gives you a visual confirmation of production quality, and allows you to identify and correct any gaps or bubbles that may form within the mold. Accura® 60 is a multi-purpose resin that works well in this capacity, and is capable of printing thinly walled cavities. When it comes to clarity, however, Accura® ClearVue™ and Accura® ClearVue™ Free are the clearest 3D printing materials in the industry. For more information, feel free to download our white paper on advancements in SLA clear materials.

SLA for pre-production

While the aim of this blog is to familiarize you with production options in SLA, I would be remiss if I did not at least acknowledge the prototyping value of this technology. After all, SLA got its start as the original rapid prototyping tech, and prototyping remains a key application that shows no signs of slowing down.

Perhaps it is better left as a topic for another time, but suffice it to say the diversity of material options for SLA does not stop with production. From materials which span a broad range of thermoplastics to exceptionally stiff nanocomposites and high temperature options (including one of my favorites, Accura® Bluestone), the world of SLA has changed substantially over the course of my career, and it continues to evolve in new and exciting directions.

What kinds of applications is SLA good for?

The accuracy and material versatility of SLA have made it a valuable tool across industries, from medical and dental to aviation and consumer goods. As I mentioned in my introduction, the main question you should ask when attempting to match an additive technology to your application, is: What are my application requirements?

SLA can answer a wide range of demands, from large part sizes and high complexity, to accelerated time to part. Clarity, temperature resistance, biocompatibility, and other material features are also available, making SLA a true contender for many projects. If it sounds like it might be a fit for yours, get in touch. We’re happy to weigh-in, answer any questions you may have, and make sure you’re on the right track.