NextDent 300 MultiJet Printer Delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

Josh Jakson - President, Evolve Dentistry

Digital dentistry has been in development for more than three decades, but only started to come into its own around 2012. Since then, advances in materials and technologies have steadily improved 3D capture, design, and output from digital dental workflows.

Evolution Dental Solutions in Buffalo, NY, has a 31-year history in digital dentistry with principals that were central to the pioneering development of automation of denture design and manufacturing at Avadent® Digital Dentures in 2013. In addition, the company has advised and consulted with companies including Exocad, University of Buffalo Dental School, 3M, and Clear Choice, among others. With a successful lab operation, and a sister company, Evolve Technology, involved in reselling of digital dentistry equipment, Evolution Dental Solutions (EDS) provides expert lab services for crowns, bridges, implants, removables, and more.

The company started out developing and using 3D CAD alongside precision milling machines for the creation of dentures and other removables and was an early adopter of 3D printing systems. Josh Jakson, Chief Case Designer at EDS, and President of Evolve Technology, joined EDS in 2013 and leads the CAD/CAM team in digital workflows.

“Digital dentistry workflows continue to accelerate,” he said. “Creating dentures using 3D printing is the emerging new standard for the industry, away from milling technology.”

He says he has watched materials for 3D printed dentures evolve well but has been testing and using 3D printers for over a decade, waiting for them to deliver output that not just matches but exceeds milling quality and precision.

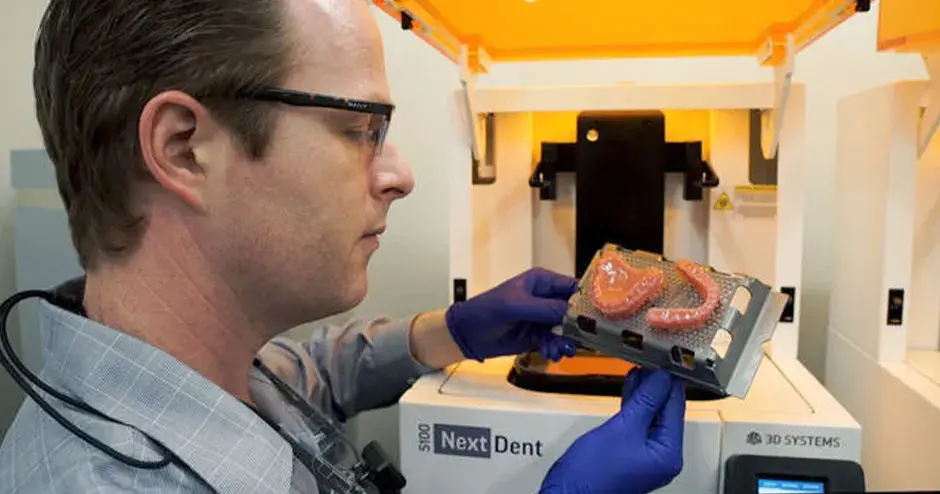

According to Jakson, the NextDent® 300 MultiJet 3D printer and its latest NextDent materials, are the evolution he has been waiting for.

“It is important that we have a consistent output, every time,” he said. “The NextDent 300 is delivering a 3D printing process that we can truly scale with.”

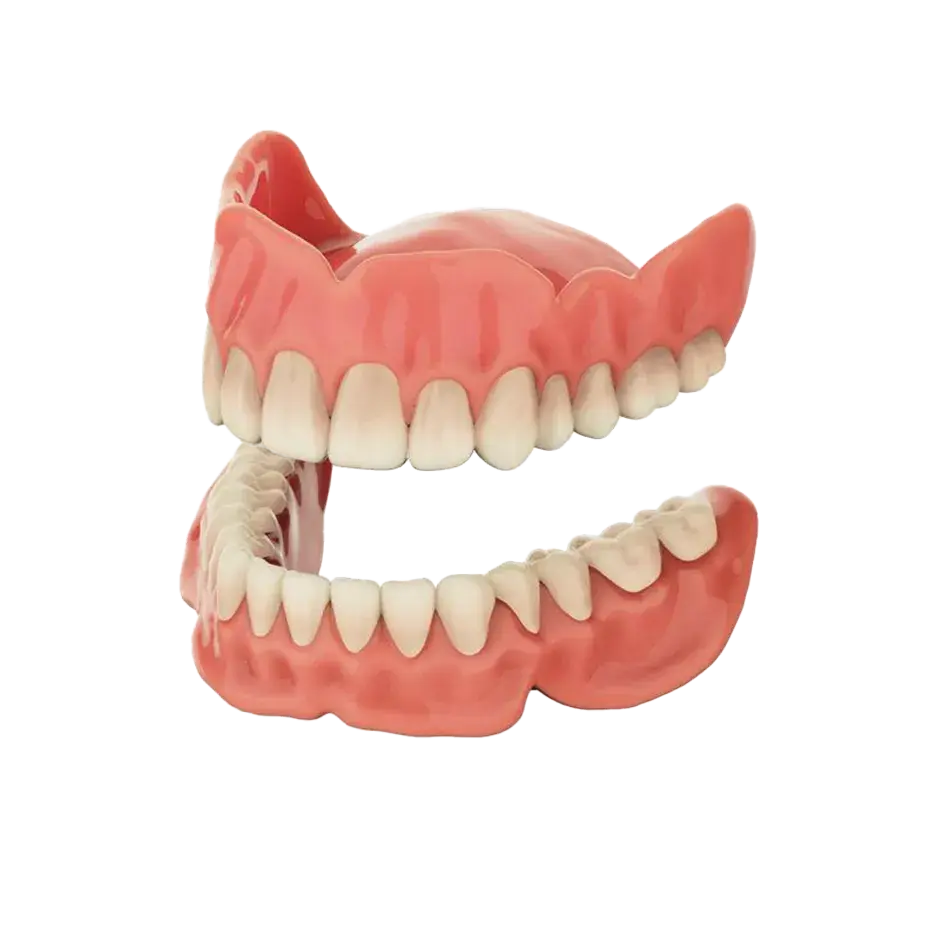

The NextDent 300 is a multi-material 3D printer from 3D Systems developed for the creation of accurate and highly aesthetic monolithic dentures. It produces patient-ready, highly realistic dentures using FDA-cleared bio-compatible materials.

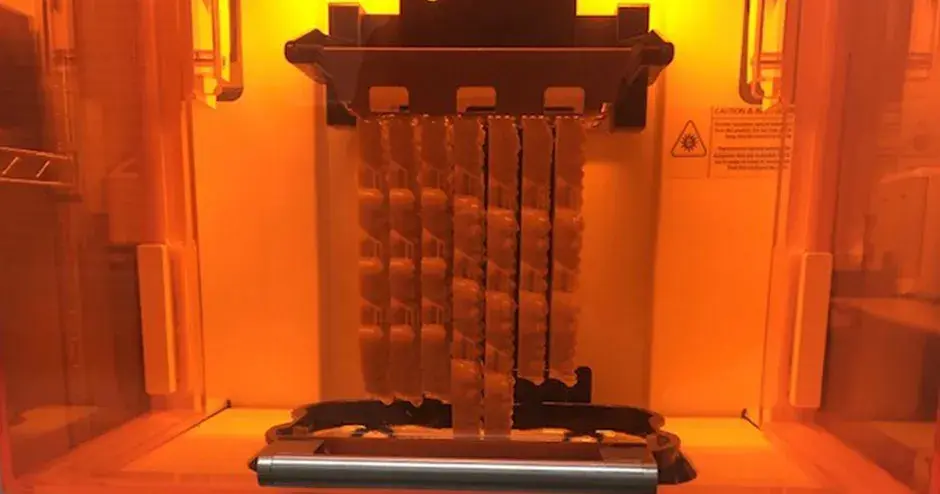

The team at EDS runs lights-out production on the NextDent 300, producing about 20-30 dentures a day and is planning to scale with an additional machine shortly.

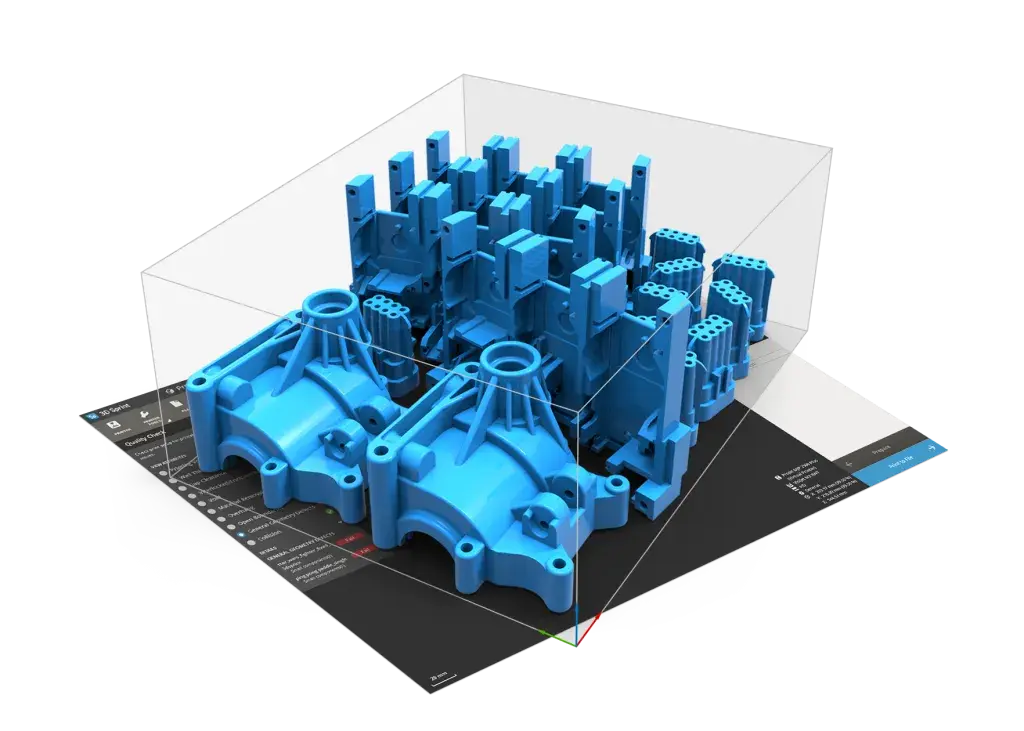

The multi-material capability of the NextDent 300 allows both the teeth and gum models to be created as a single part. With a print build area of 294 x 211 x 50 mm (11.6 x 8.3 x 2.0 in) it has enough space for an average of 15 dentures in each run. Materials used in the NextDent 300 include: NextDent Jet Base, NextDent Jet Teeth, and Wax support material. The machine is operated by 3D Sprint software from 3D Systems, which Jakson says is easy to use and accelerates the production speed.

“It is not just the printer accuracy that is impressive,” said Jakson. “You can see the difference in the material itself. They are cured 100% on the build plate which is faster, and we are getting better results than ever before. The materials don’t discolor and the dentures exceed the benchmark standard.”

Jakson points out that the true test of new dentures, regardless of production method, is if there are complaints from customers.

“We have had no failed builds so far and have had zero customer complaints, which speaks volumes,” he said “The materials are next-level compared to other materials on the market, and I think the NextDent 300 is the ‘coming of age’ for digital dentistry.”