GPS Digital RPD is a Florida-based dental lab specializing in high quality partial frameworks and flexible partial dentures. Working with a wide range of dental labs and dentist practitioners, the company has developed a reputation of quality through utilizing the most advanced 3D printing technologies to improve denture output and accelerate throughput for clients.

Removable Partial dentures (RPDs) have grown in popularity as digital technologies have improved. Using a digital workflow, 3D scan data of a patient’s mouth or of a traditional impression, is uploaded to the company’s online portal. From there, the GPS team, led by General Manager, Josh Williams, creates a CAD/CAM model ready for printing on the company’s two DMP Flex 200 metal 3D printers and the new NextDent® 300 MultiJet 3D printer – both from 3D Systems.

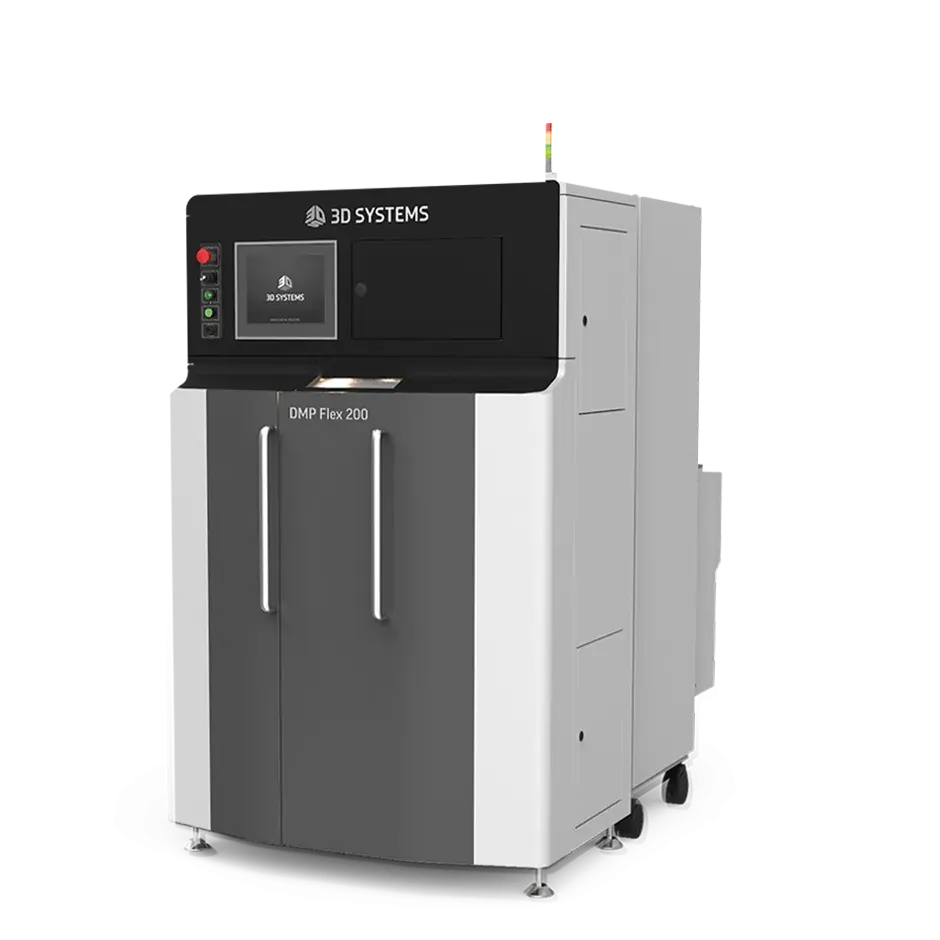

About the DMP Flex 200

With a build volume of 140 x 140 x 115 mm (5.51 x 4.53 in) and 500W laser source, this metal 3D printer leads to reduced cost per part and faster delivery times.

The DMP Flex 200 is designed for professional 3D printed metal manufacturing of small, complex, fine-detail metal parts at high quality. The typical accuracy on small metal parts is +/-50 up (+/-0.002 inches), on large parts +/_0.2%. Repeatablity from part to part is approximately 20 up (0.0008 inches). Materials used in the DSMP Flex 200 include: Cobalt Chrome, Titanium, and 316 L Stainless Steel.

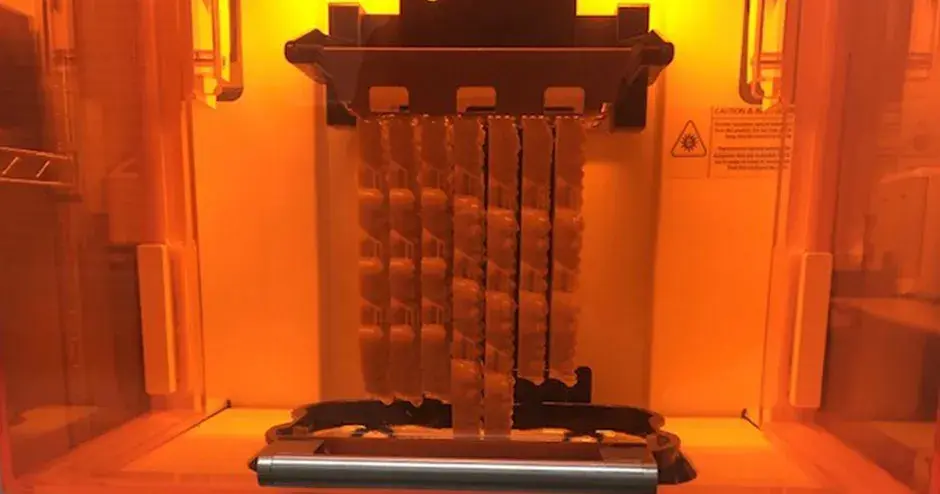

"We are producing about 130 metal frameworks a day now,” said Williams. “Our two DMP Flex 200 systems can keep up with that rate, whereas older machines could not. We do ‘lights out’ production, so the team has a whole new set of frames to work on every morning.”

Williams is keen to point out that the DMP Flex 200 systems are reliable enough to leave running overnight, and, barring an unanticipated event such as a power outage, deliver very precise parts output every time.

“The output of the DMP Flex 200 is flawless every time,” he says. “We can’t say enough good things about the machine, the software, and the quality of parts produced.”

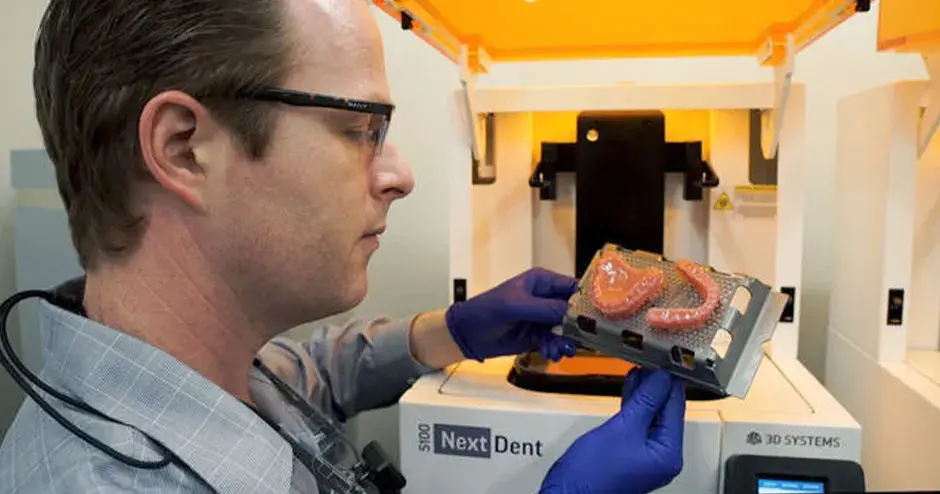

The NextDent 300 is a multi-material 3D printer for the creation of accurate and highly aesthetic monolithic dentures. It produces patient-ready, highly realistic dentures using FDA-approved bio-compatible materials. “The NextDent 300 printer is a night-and-day difference to alternatives,” says Williams. “There are a lot of patient cases that have very limited space or really awkward shapes, where there is only a few millimeters of space. Handling these cases manually is almost impossible. But this printer makes it easy.”

The multi-material capability of the NextDent 300 allows both the teeth and gum models to be created as a single part. With a print build area of 294 x 211 x 50 mm (11.6 x 8.3 x 2.0 in) it has enough space for an average of 15 dentures in each run. Materials used in the NextDent 300 include:

- NextDent Jet Base LT

- NextDent Jet Teeth White

- NextDent Jet Teeth Yellow

- Wax support material

“The two unique materials and the NextDent 300 make incredibly realistic dentures,” says Williams. “This is way above and beyond the accuracy and output of manual processes, the material colors are nearly perfect, and we have zero delamination.”

NextDent 300

The NextDent 300 produces one-piece, removable dental protheses and custom-blended teeth shades. This solution delivers an unparalleled combination of outstanding aesthetics and distinctive fracture resistance. The printer blends polymers on-demand to deliver accurate shade matching.

This system is tuned to save time and build productivity for direct denture production by going from CAD data to a multi-material, monolithic denture without the need for any additional assembly. With a build space of 294 x 211 x 50 mm (11.6 x 8.3 x 2.0 in) and a layer thickness os 32 um, this system delivers minimum post-processing, reduced material waste, lowers costs, and enhances scalability for dental labs.

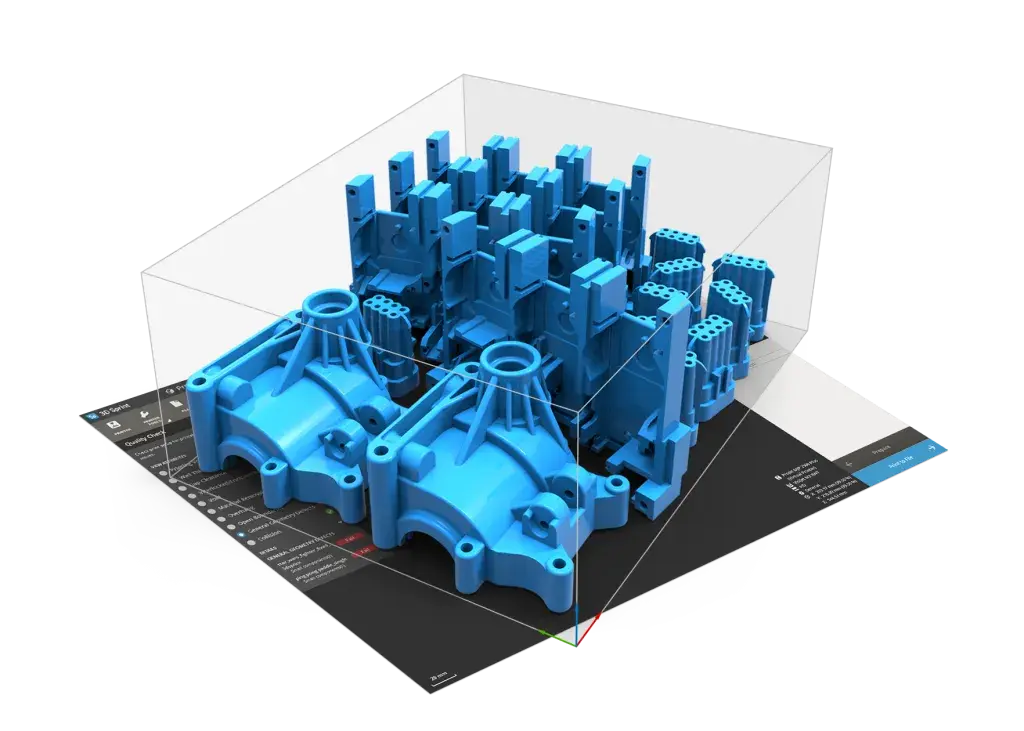

The team at GPS uses a dental CAD/CAM software called 3Shape, as well as 3D Sprint® print management software to support this workflow. 3D Sprint manages the 3D printer setup and operations, with tools for nesting parts, customizing teeth shades, and adding flush-to-surface engraving to each part.

“The 3D Sprint software makes all this absurdly easy,” says Williams. “It’s much easier now that the technician doesn’t have to look at 40 partial pieces and wonder ‘where do these go?’ Now the labels are added digitally and match to the client reference.”

3D Sprint

3D Sprint is exclusive software from 3D Systems for preparing and optimizing CAD and polygon data and managing the additive manufacturing (AM) process for 3D Systems plastic printers.

3D Sprint enables seamless 3D data import, preparation, part nesting, job monitoring, as well as digital labelling of parts.

Once both the frames and dentures are matched, the team at GPS use a piece of wax to temporarily combine both pieces and these are sent back to the client for testing and checking.

“We send these back to test in the patient’s mouth,” says Williams. “Once they are approved, they come back to us and we affix them permanently with acrylic and send them back out. It’s really that easy.”

According to Williams, the metal and plastic parts are designed to snap together “like a Lego” but the dimples in the metal frame allow for a more permanent attachment with the acrylic.

“The holes for retention on the frame act as the alignment for the finished piece,” he says. “There’s no questioning whether it’s lined up, it just fits right in.”

Although GPS has been using digital workflows for RPDs with their small fleet of DMP Flex 200s for nearly 3 years, the addition of the NextDent 300 is signaling a new level of productivity for the company.

“Our team is far more productive now and this is giving them an opportunity to extend their digital dental skills,” says Williams. “We are always busy but we encourage the team to cross-train into more digital technologies so they become even more productive.”

In terms of productivity, Wiliams maintains that with this new digital workflow, they can produce the first finished RPD to send to the client within nine days, often less.

“I could do it within four days, easily, but we always have to factor in Florida storms, power outages and such, so we have to set expectations,” says Williams. “Previously, even with a digital workflow and older 3D printers, the turn-around time was 15 working days, easily. So this is a huge improvement, not only in production time but with visibly improved quality and fit.”