From manufacturing to e-commerce, effective conveyor systems make the pace of modern life possible. Founded in 1989, Span Tech is recognized as a global leader in unique and customizable conveyor systems that are used in a wide range of industries, from food and beverage production to packaging distribution, cosmetics, pharmaceuticals, and more. Span Tech has built and sustained its reputation through constant innovation and a dedicated team of engineers who are committed to introducing meaningful improvements to conveyor capabilities.

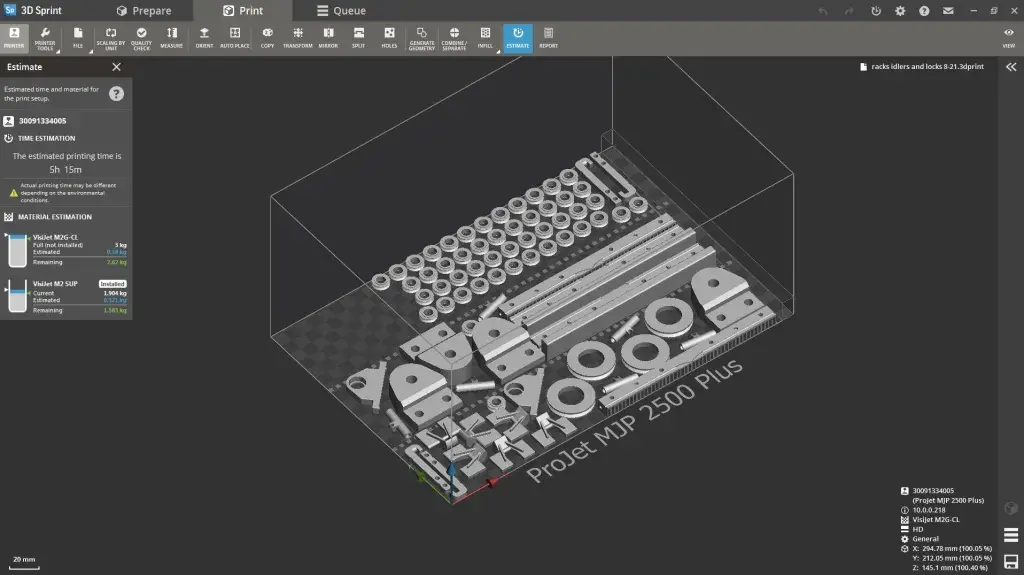

Span Tech designs and manufactures modular conveyors made with durable plastic chain systems that can meet any size and motion requirement, from inclining, to curving, to helical. In the world of smoothly running high-speed switches, spirals and wedges, prototyping is key for cost-effective development. Always on the lookout for innovative solutions to keep ideas and test systems flowing, Span Tech owner Bud Layne has made 3D printing part of his company’s development process for the past several years. To further increase its in-house capability, Span Tech decided to purchase a 3D Systems ProJet® MJP 2500 Plus and VisiJet® Armor (M2G-CL) and VisiJet® M2R-BK materials. Since installation, Span Tech has used these 3D printed parts to validate designs within a test system to introduce faster and more frequent design cycles, increase innovation, and boost confidence in final tooling investments.

Confidence in final molding investment

Before purchasing its MJP system, Span Tech prototyped using a small desktop 3D printer, occasional one-off 3D printed parts, and traditional machining, but Layne wanted his engineers to have access to a faster and more robust in-house solution to enable more thorough and cost-effective development. The accuracy and material properties of the ProJet MJP 2500 Plus and VisiJet materials answered those requirements and fit seamlessly into Span Tech’s workflow.

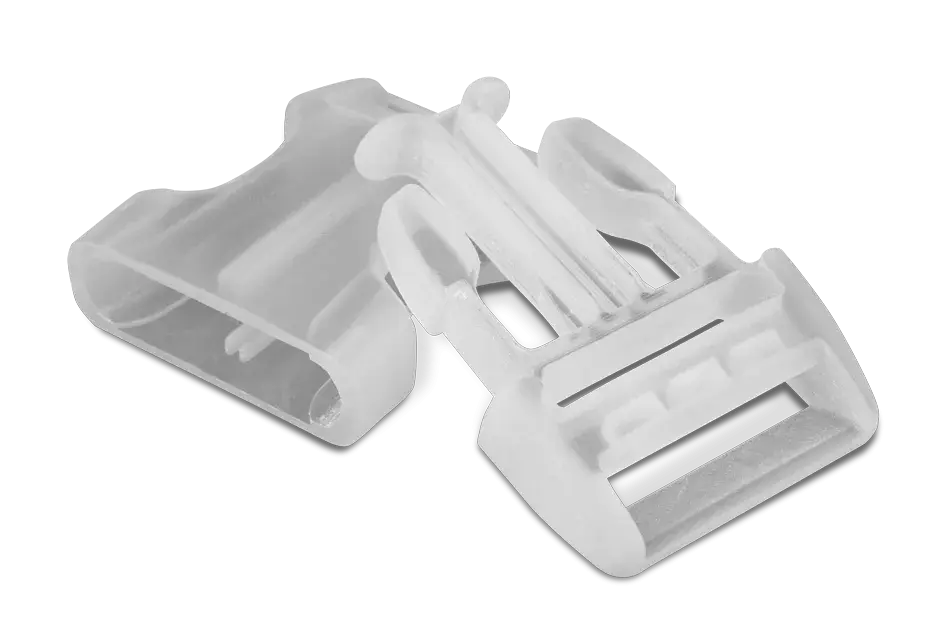

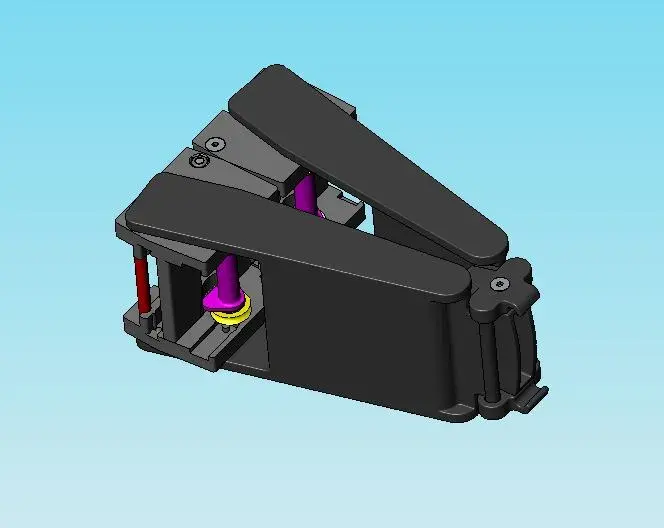

Span Tech’s final conveyor systems are an injection-molded plastic assembly of eleven to twelve parts, depending on the component’s placement within the system. In order to prototype these parts, Span Tech R&D Engineer Scott Barbour prints them in full size on the ProJet MJP 2500 Plus and assembles them just like the final product, with functional features such as snap fits, sliding connectors, and integrated metal pieces including shafts and bearings. Taking advantage of the ProJet’s build platform and accuracy, Span Tech is able to print parts ranging from the largest, which are roughly six inches by four inches, to the smallest, which are less than half an inch in diameter and only a few millimeters thick. (The ProJet MJP 2500 Plus has a build platform of 11.6 x 8.3 x 5.6 in (294 x 211 x 144 mm) and offers resolution of 800 x 900 x 790 DPI, 32µ layers.)

“With the ProJet 2500 we can go through trial and error before we invest in tooling so we don’t have to spend time and money updating the mold,” says Barbour. “The molds for each of these eleven or twelve parts cost thousands of dollars apiece, so getting the part design right before making the molds is a big cost saver.”

Materials that match functional requirements

A big motivation behind Span Tech’s purchase of the ProJet MJP 2500 Plus was to expand in-house material options. According to Barbour, the previous 3D printing solution Span Tech used did not offer the right material properties and produced parts that were brittle and grew fragile over time. With the ProJet MJP printer, Span Tech now uses two different VisiJet materials, capitalizing on the strengths of each to achieve the optimal properties required for its prototypes. These prototypes use both VisiJet Armor (M2G-CL), a tough, ABS-like clear performance plastic, and VisiJet M2R-BK, a high modulus, rigid black plastic.

“VisiJet Armor is a lot stronger than the material we used to use, and it doesn’t break and isn’t brittle,” says Barbour. He also says the rigid black material is durable and good for weight bearing: “All the VisiJet parts print out true to the CAD models and we are able to run them through our test system to evaluate the feasibility of our designs,” Barbour says.

Accelerating development cycles with real world feedback

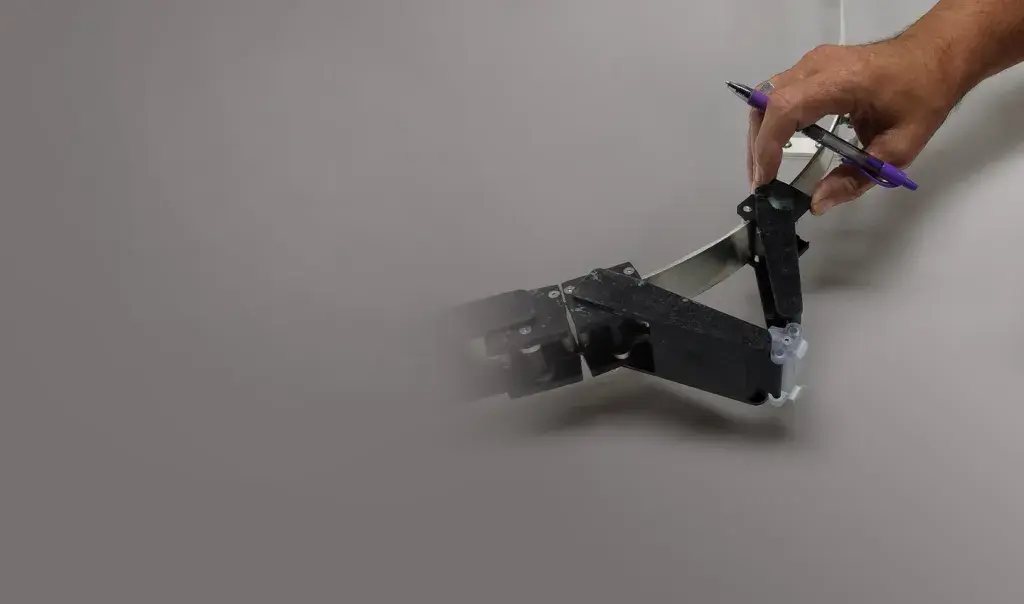

Most recently, Span Tech has been using its ProJet to develop a new guide rail system. According to Barbour, the printer has been invaluable in accelerating design iterations and enabling the company to deliver consistent improvements. The Span Tech bracket is designed to move and can both collapse and extend. To prototype these brackets, Barbour prints each part separately and assembles them to get a sense of how the final product will fit together. When anticipated clearances are not viable once prototyped, updating the design is a simple matter of tweaking the CAD model in SOLIDWORKS® and printing it again. “We’ve gone through several cycles where we’ll set everything up and decide something needs to change, so we update each CAD file, print them out and try again,” says Barbour. For the guide rail system, Barbour says he has printed twenty or thirty test parts to perfect the final performance.

Smooth workflow keeps development in motion

Span Tech reports an easy transition from CAD file to 3D printed part and a more streamlined post-processing operation than previously experienced. Every 3D Systems’ plastic printer comes with 3D Sprint® software for plastic additive manufacturing, which Barbour says is simple to learn and navigate: “3D Sprint is intuitive and easy to use. I was able to figure it out before anyone even had time to show me, and we were able to train our intern on it in no time at all.”

Once parts have been printed, post-processing with the ProJet Finisher takes about an hour of hands-off time to melt the support material, followed by about 20 minutes in the ultrasonic cleaner with oil. The ProJet Finisher is a post-processing accessory offered by 3D Systems that alleviates the need for manual scrubbing of parts. According to Barbour, using oil delivers VisiJet Armor parts that are almost crystal clear, and VisiJet M2R-BK parts that are richly black. “I just take them out of the ultrasonic cleaner and wipe them off with paper towels and am good to go,” says Barbour.

Looking for future opportunities

The success Span Tech has had in prototyping its conveyor system assemblies has gotten the company thinking about other opportunities for 3D printing for its product lineup. “Once you get used to working with this capability, you start designing things that would work better for you, but that are only possible with 3D printing,” says Barbour. Although Span Tech is not yet using 3D printing for production, it is interested in expanding the range of its 3D printed applications to extend the time and cost savings it has experienced in prototyping.

For more information about rapid prototyping with 3D printing, download our free eBook.