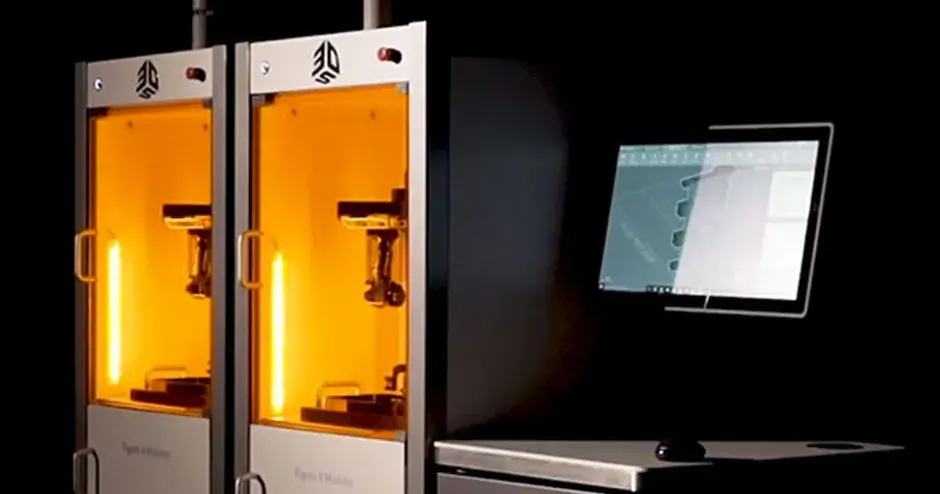

Our Difference

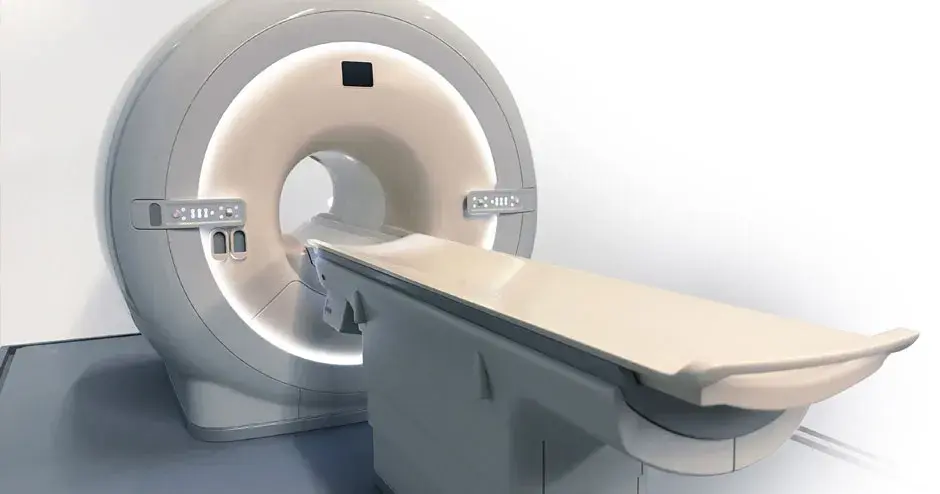

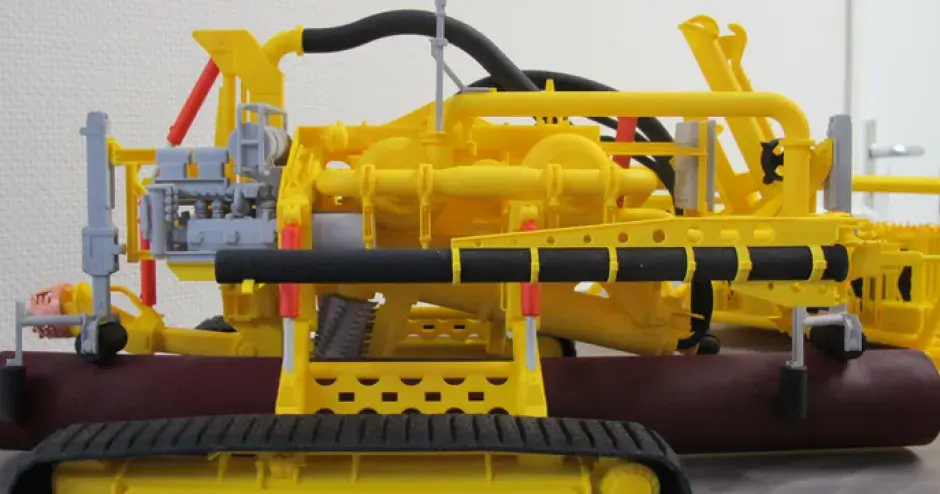

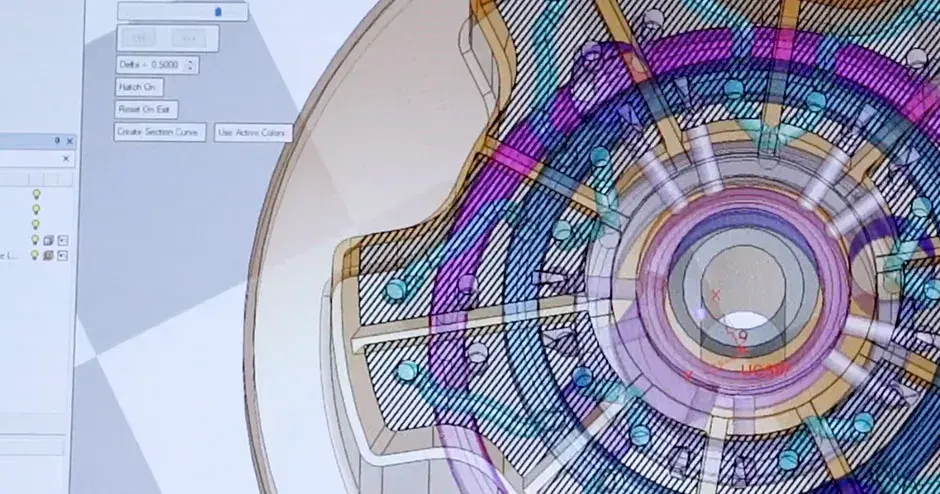

3D Systems' visual and functional prototyping service delivers a unique combination of 3D printing and materials technologies, traditional subtractive production processes, engineering expertise, and artistic finishing skills near you to make your designs come to life early in the product development stage.