Customer Support Documentation

Find safety data sheets, user manuals, order supplies, and more

High contrast gray plastic for long-term use parts with balanced thermal and mechanical properties

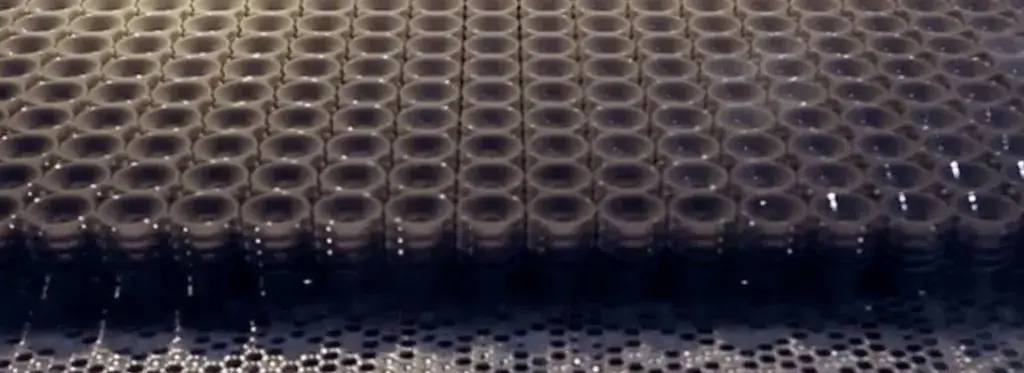

Figure 4® Rigid Gray is a production-grade gray material that delivers a surface finish comparable to injection molding and provides long-term environmental stability. The high contrast gray color is ideal for parts requiring high feature definition like texture and lettering. This material is suitable for painting and plating and is recommended for prototyping and production for consumer products and general use on small parts requiring high detail and accuracy.

This resin exhibits thermoplastic behavior with necking at the break, making it ideal for rigid snap-fit applications such as covers. It also features 72˚C heat deflection temperature and 30% elongation at break. Fast print speeds and simplified post-processing speeds enable exceptional throughput.

Figure 4 Rigid Gray is tested to 8 years of indoor and 1.5 years outdoor mechanical performance per ASTM D4329 and ASTM G194 methods, ensuring that printed parts remain functional and stable for long periods in real-world conditions.

“We are using the Figure 4 Rigid Gray material to rapidly deliver functional parts for our consumer sporting goods lines, including ski helmet accessories, bicycle lighting covers, and sporting shoe soles and components. We are very impressed with the performance of this material and the overall productivity of the Figure 4 solution. Out of the printer, parts display excellent dimensional accuracy and perfect quality, comparable to injection-molded plastics. The attractive gray color of the material is also ideal for highlighting fine surface details and texture-on-part.”— Grégoire Mercusot, Material Engineer, Decathlon

The full suite of mechanical properties is given per ASTM and ISO standards where applicable. All parts are conditioned per ASTM recommended standards for a minimum of 40 hours at 23 °C, 50% RH. Material properties include physical and mechanical properties and thermal, UL flammability, and electrical (dielectric strength, dielectric constant, dissipation factor, and volume resistivity).

Figure 4 technology prints parts that are isotropic in mechanical properties meaning the parts printed along either the XYZ axis will give similar results. Parts do not need to be oriented to get the highest mechanical properties, improving the degree of freedom for part orientation for mechanical properties.

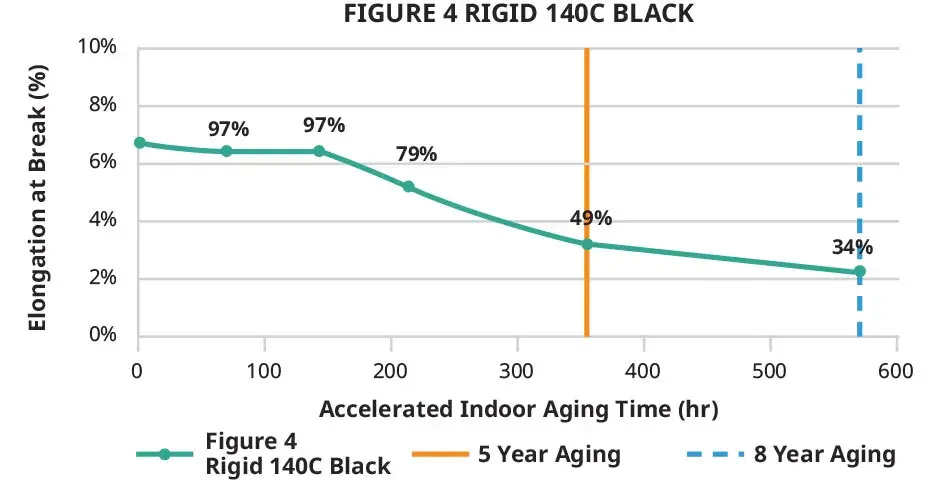

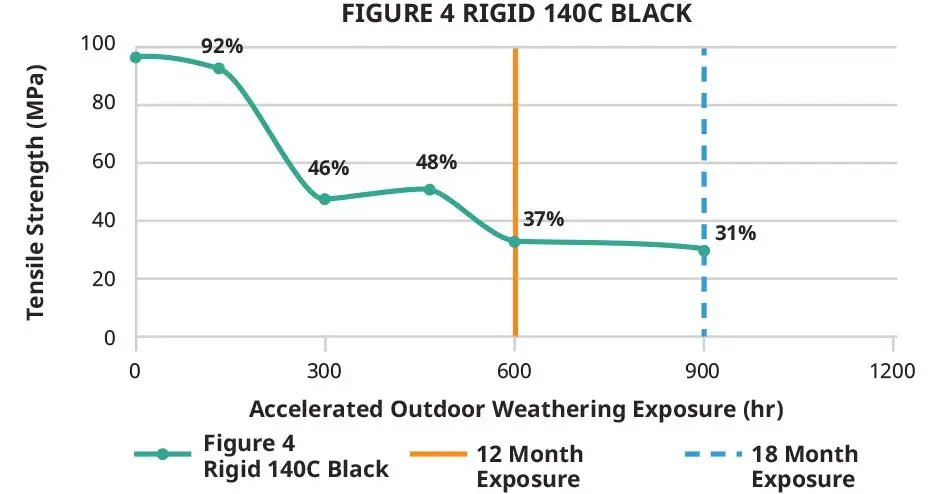

Figure 4 Rigid Gray is engineered to give long-term environmental UV and humidity stability and long-lasting gray color. This material has been tested for its ability to retain a high percentage of its initial mechanical properties over a period of time. This test data provides real performance conditions to consider for the application or part.

The charts show a sampling of the dataset. The full data sheet includes indoor and outdoor stability data for tensile strength, elongation at break, tensile modulus, and impact strength. The actual data value is on the Y-axis, and data points are a % of the initial value.

Tested per ASTM D4329 standard method.

Tested per ASTM G194 standard method.

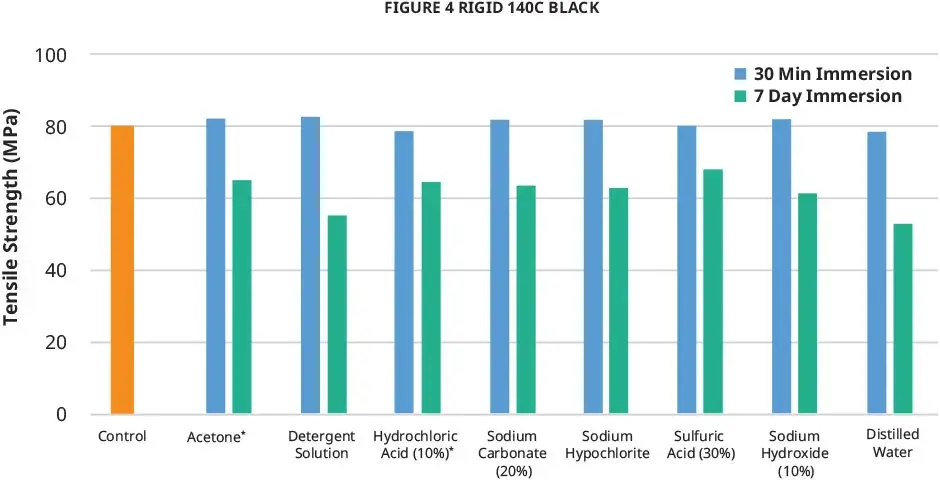

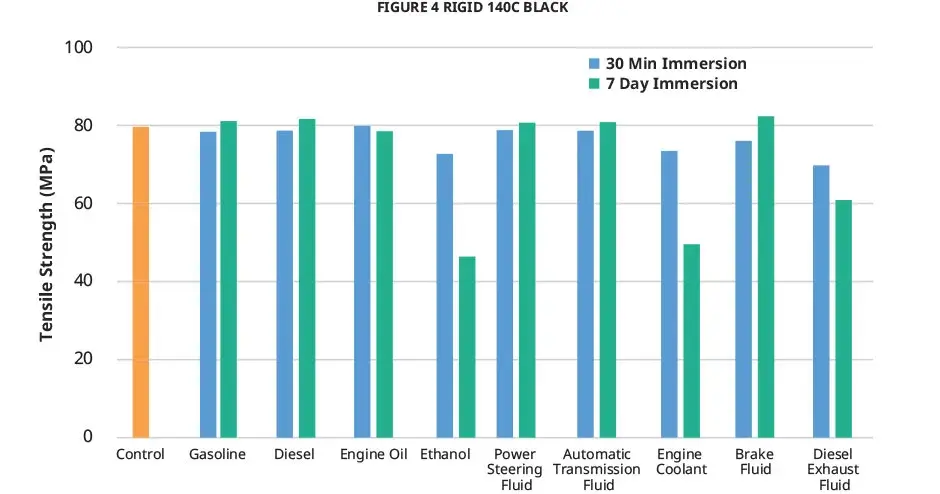

Hydrocarbons and cleaning chemical compatibility can be critical to application compatibility. Figure 4 Rigid Gray parts were tested for sealed and surface contact compatibility per ASTM D543 test conditions and per USCAR2 test conditions. The notched impact strength is shown below. The full data sheet includes additional data tables for tensile strength, tensile modulus, and elongation at break.

* Note: Not all products and materials are available in all countries – please consult your local sales representative for availability.

Learn how to evaluate materials for production AM with mechanical, thermal and electrical properties, isotropic properties, environmental stability, chemical and fluid compatibility and biocompatibility.

Production-grade, rigid material for production parts

High temperature resistant translucent plastic with HDT over 300°C

High stability, durable and flexible plastic

Merges the best of SLA and light projection technologies to deliver superior performance and productivity

Industry’s first customizable, fully-integrated factory solution for direct digital production

Scalable, semi-automated 3D manufacturing solution designed to scale with growth

Ultra-fast and affordable for same day prototyping and low-volume production

High speed, high precision with repeatable accuracy for tool-less manufacturing

Find safety data sheets, user manuals, order supplies, and more

3D print with plastics to build almost anything - used for prototyping, manufacturing, anatomical models and more. Select a plastic material and 3D technology to deliver the characteristics you need.