Figure 4 FLEX-BLK 20 is a durable, flexible material. It is great for enclosures and high impact applications.

Durable, flexible, high impact resistant material with long-term environmental stability.

Figure 4 FLEX-BLK 20 is a durable, flexible material. It is great for enclosures and high impact applications.

Figure 4® FLEX-BLK 20 is a flexible, high impact-resistant material for extremely durable black parts with the look and feel of production polypropylene. Great for functional prototypes, enclosures and assemblies, as well as short-run production parts, this fatigue resistant material provides outstanding flexibility and accuracy, enabling many applications.

The full suite of mechanical properties are given per ASTM and ISO standards where applicable. All parts are conditioned per ASTM recommended standards for a minimum of 40 hours at 23 °C, 50% RH. Material properties include physical and mechanical properties, as well as thermal, UL flammability, and electrical (dielectric strength, dielectric constant, dissipation factor, and volume resistivity).

Figure 4 technology prints parts that are isotropic in mechanical properties meaning the parts printed along either the XYZ axis will give similar results. Parts do not need to be oriented to get the highest mechanical properties, further improving the degree of freedom for part orientation for mechanical properties.

Learn how to evaluate materials for production AM with mechanical, thermal and electrical properties, isotropic properties, environmental stability, chemical and fluid compatibility and biocompatibility.

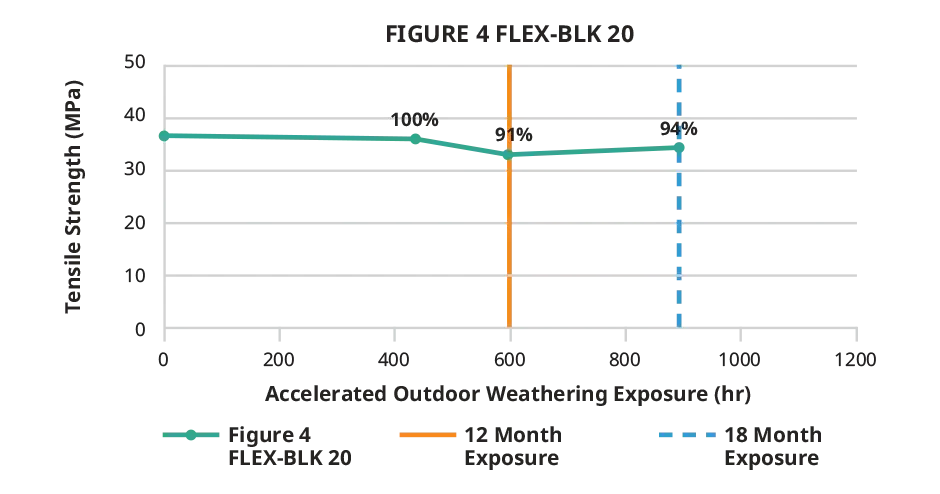

Figure 4 FLEX-BLK 20 is engineered to give long term environmental UV and humidity stability. This means the material is tested for the ability to retain a high percent of the initial mechanical properties over a given period of time. This provides real design conditions to consider for the application or part.

Below is a sampling of the dataset. The full datasheet includes Indoor and Outdoor Stability data for Tensile Strength, Elongation at Break, Tensile Modulus and Impact Strength. Actual data value is on Y-axis, and data points are % of initial value.

Tested per ASTM D4329 standard method.

Tested per ASTM G154 standard method.

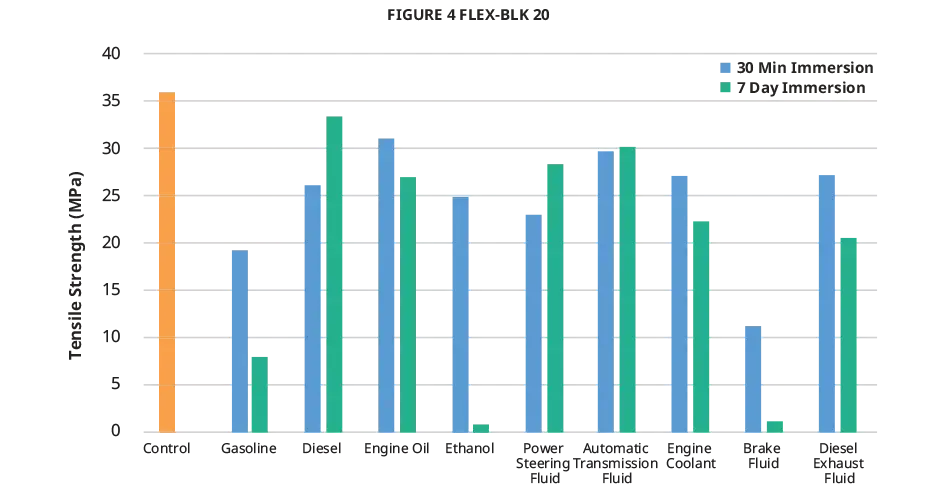

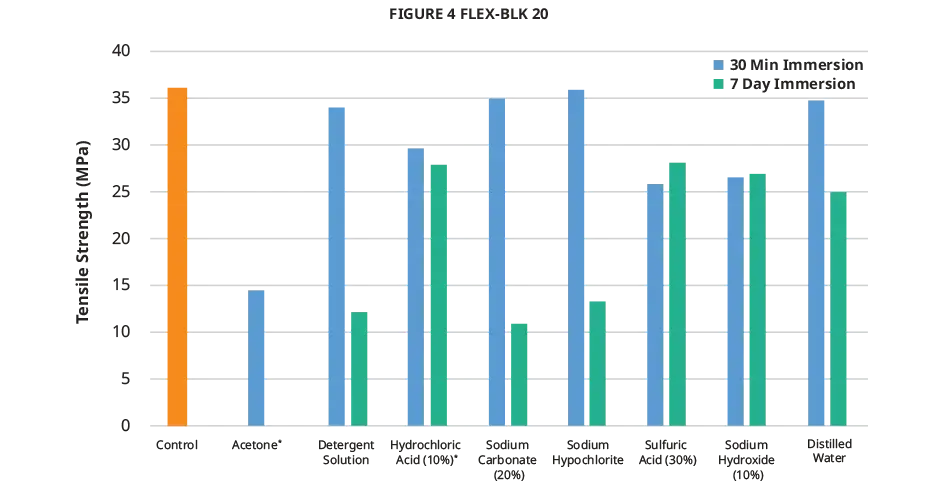

The compatibility of a material with hydrocarbons and cleaning chemicals is critical to part application. Figure 4 PRO-BLK 10 parts were tested for sealed and surface contact compatibility per ASTM D543 test conditions and per USCAR2 test conditions. Tensile Strength (MPa) is shown below. The full datasheet includes additional data tables for Tensile Modulus, Elongation at Break and Notched Impact Strength.

* Note: Not all products and materials are available in all countries – please consult your local sales representative for availability.

Production-grade, rigid material for production parts

Durable, hard rubber-like material

High temperature resistant translucent plastic with HDT over 300°C

Discover new levels of speed, quality and affordability including improvements to toughness, durability, high temperature deflection and elastomeric properties

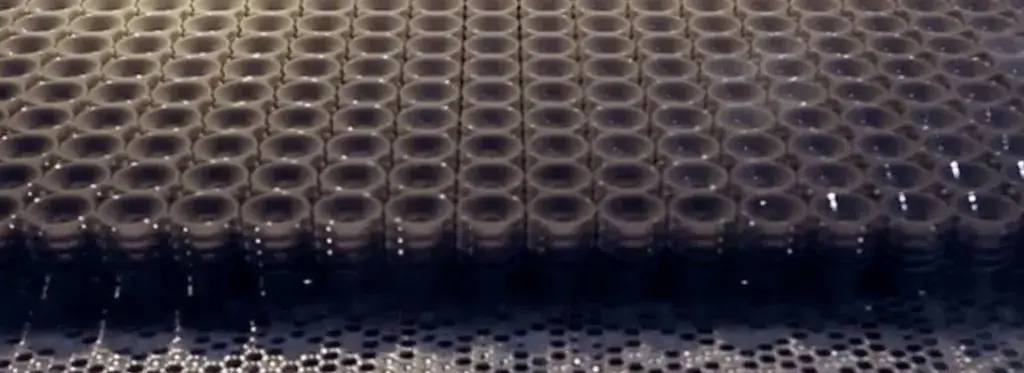

Fatigue resistant window clip in Figure 4 FLEX-BLK 20 for long-term performance.

Industry’s first customizable, fully-integrated factory solution for direct digital production

Scalable, semi-automated 3D manufacturing solution designed to scale with growth

Ultra-fast and affordable for same day prototyping and low-volume production

High speed, high precision with repeatable accuracy for tool-less manufacturing

Merges the best of SLA and light projection technologies to deliver superior performance and productivity

Find safety data sheets, user manuals, order supplies, and more

3D print with plastics to build almost anything - used for prototyping, manufacturing, anatomical models and more. Select a plastic material and 3D technology to deliver the characteristics you need.