High throughput production of pure wax jewelry patterns for lost wax casting

Get high-quality, precision jewelry casting patterns with the MJP 300W 3D printer. This 100% wax printer adjusts to your workflow, delivering several short-run batches a day or larger builds the next day with fast print speeds and large build volume capacity. This printer is perfect for high-volume production of fine jewelry casting patterns with unique productivity, efficiency, quality and design freedom.

Interested in purchasing this printer?

You Might Also Be Interested In

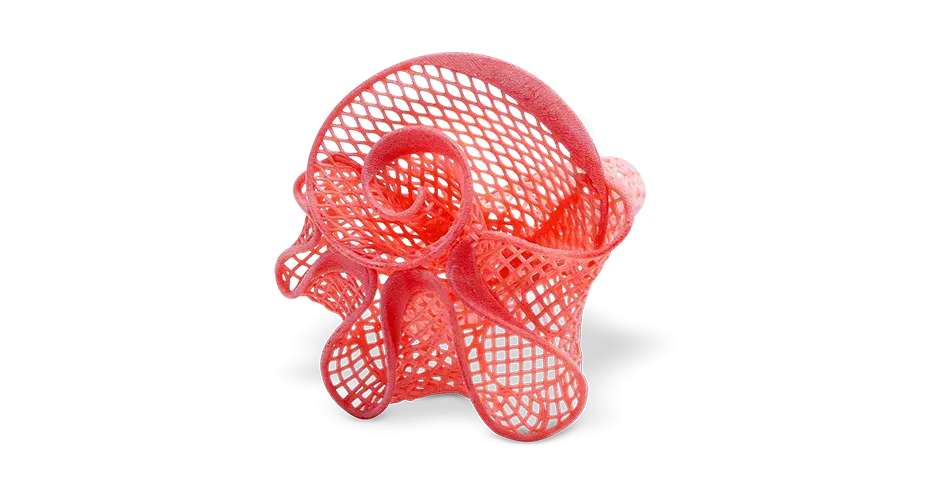

VisiJet Wax Jewel Ruby (MJP)

Durable, flexible, and dimensionally stable 3D printed pure wax casting patterns

VisiJet Wax Jewel Red (MJP)

Durable and flexible, 100% wax for intricate jewelry casting patterns

VisiJet M2 CAST (MJP)

Durable, 100% wax for precision jewelry metal casting patterns

3D Connect

Remote Diagnostics Management Software for 3D Printers